Device and method for preparing silicon-calcium base material and sulfuric acid from industrial byproduct gypsum

A technology for industrial by-products of gypsum and calcium silicon, which is applied in the field of solid waste recycling, can solve the problems of difficulty in ensuring the atmosphere, reduced processing intensity of the rotary kiln, and easy scarring of materials in the kiln, so as to reduce the decomposition reaction temperature and improve the product quality. Economic value, reducing the effect of the powder homogenization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

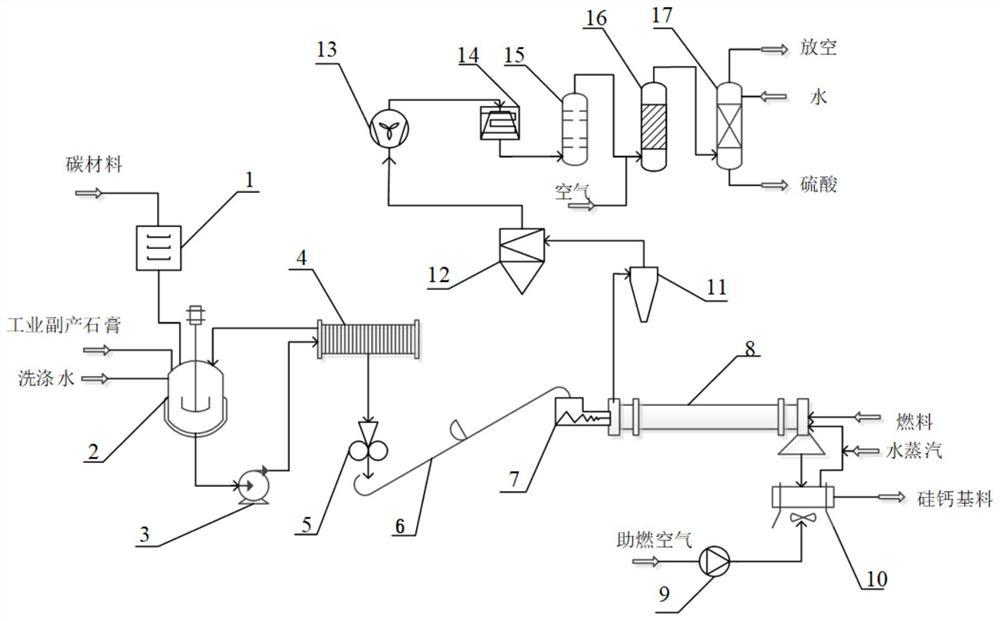

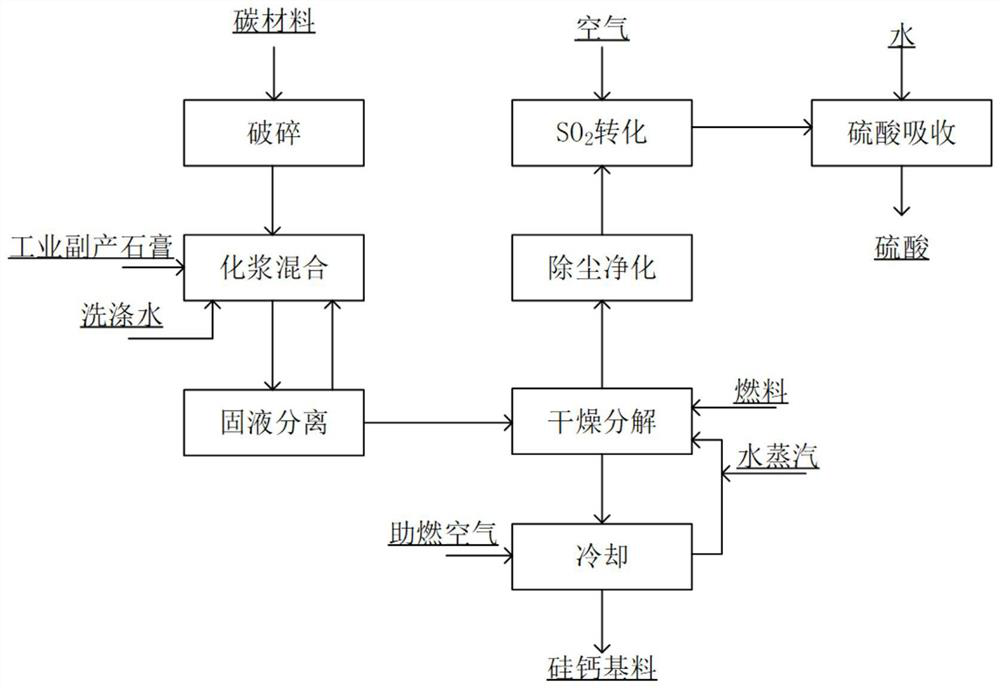

[0078] This embodiment provides a kind of industrial by-product gypsum to prepare the device of silicon-calcium base material and sulfuric acid, such as figure 1 As shown, the device includes a slurry mixer 2, a solid-liquid separator 4, a filter cake breaker 5, and a dry decomposition reactor 8 connected in sequence;

[0079] Wherein, a carbon material inlet, a gypsum inlet, a washing water inlet and a slurry outlet are set on the slurry mixer 2, and the slurry outlet is connected to the inlet of the solid-liquid separator 4, and the slurry outlet is connected to the inlet of the solid-liquid separator 4. A slurry mixing pump 2 is set on the pipeline between the mixer and the solid-liquid separator 4; a carbon material pulverizer 1 is set at the carbon material inlet; the solid outlet of the solid-liquid separator 4 is connected to the filter The inlet of the cake breaker 5 is connected; the circulating water inlet is set on the slurry mixer 2, and the liquid outlet of the solid

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap