Deburring device for wooden pencil production

A technology for pencils and wood, which is applied in the field of deburring devices for the production of wooden pencils. It can solve the problems of inconvenient use, high cost, and inefficient processing methods, and achieve the effects of convenient grinding and avoiding collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

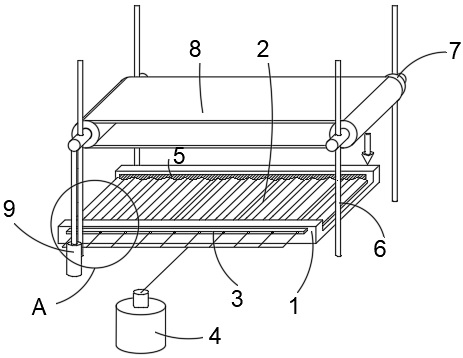

[0037] The present embodiment provides the concrete structure of slideway, as figure 1 As shown, a deburring device for wooden pencil production includes: a slideway 1, a conveyor belt 2 for driving the pencil to move is arranged above it, and an air intake plate 3 is provided on the front side of the slideway 1, and the air intake plate 3 It is connected with the air pump 4 provided outside by a gas pipe;

[0038] In some examples, the section of the slideway 1 is "concave" shape, and the abrasive belt 8 can completely enter the groove of the slideway 1; the conveyor belt 2 is located in the groove of the slideway 1, and the section of the conveyor belt 2 is wavy , wooden pencils can be placed in each groove on the conveyor belt 2; the surface of the air intake plate 3 is provided with several air passages, and the surface formed by blowing out the airflow from the air passages is located above the conveyor belt 2; the surface of the slideway 1 and the air intake plate 3 The op

Embodiment 2

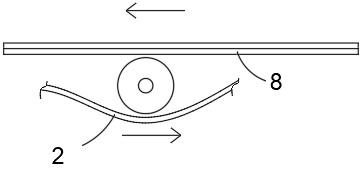

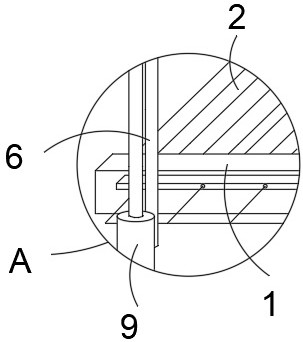

[0044] The present embodiment provides the concrete structure of abrasive belt, as figure 2 and 3 As shown, the frosted belt 8 is distributed directly above the slideway 1, the two ends of the frosted belt 8 are provided with drive rollers, and the two ends of the drive rollers are all penetrated by a slide bar 6, and the surface of any slide bar 6 A telescopic cylinder 9 is installed, and the telescopic cylinder 9 is used to drive the abrasive belt 8 to move up and down.

[0045]In some examples, the outer surface of the abrasive belt 8 is set as a frosted layer, and a drive motor 7 is installed on any group of drive roller ends for driving the abrasive belt 8; several slide bars 6 are distributed in parallel, and the slide bars 6 The plane formed by vertically running through the slideway 1; the outer wall of the telescopic cylinder 9 is fixedly connected with the corresponding slide rod 6, and one end of the supporting piston rod of the telescopic cylinder 9 is fixedly conne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap