High-shrinkage biaxially oriented polyamide film as well as preparation method and application thereof

A polyamide film, biaxially oriented technology, applied in the field of high shrinkage biaxially oriented polyamide film and its preparation, can solve problems such as insufficient shrinkage rate of BOPA film, achieve excellent puncture resistance, wide application prospects, high tensile strength the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

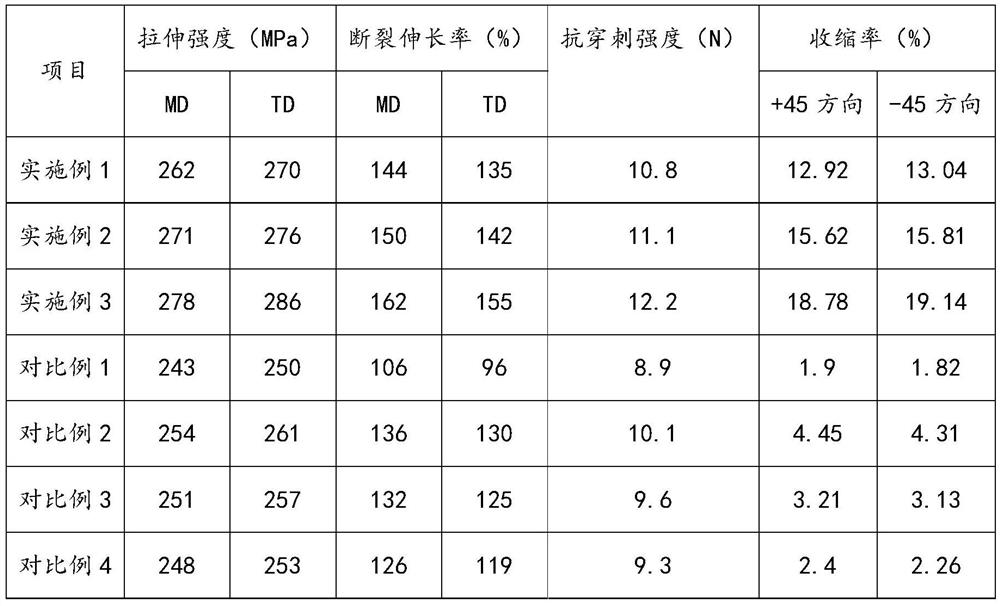

Embodiment 1

[0035] A high-shrinkage biaxially oriented polyamide film with a thickness of 15 μm and a first skin layer and a second skin layer with a thickness of 1.8 μm.

[0036] The first surface layer is composed of 50% nylon 6, 45% nylon composition A and 5% anti-stick nylon masterbatch; the core layer is composed of 41% nylon 6, 54% nylon composition B and 5% nylon secondary material; The second skin consisted of 44% Nylon 6, 55% Nylon Composition A and 1% release nylon masterbatch.

[0037] Nylon composition A is composed of bio-based nylon 56, nylon 66 / 612 and maleic anhydride graft-modified polyether block amide copolymer, and the content ratio is 6:2:0.5.

[0038] Nylon composition B is composed of bio-based nylon 56, nylon 66 / 6, and maleic anhydride graft-modified polyether block amide copolymer, and the content ratio is 6:1.5:0.5.

[0039] Its preparation method is as follows:

[0040] B1. The components in the first surface layer, the core layer and the second surface layer

Embodiment 2

[0044] A high-shrinkage biaxially oriented polyamide film with a thickness of 15 μm and a first skin layer and a second skin layer with a thickness of 1.8 μm.

[0045] The first skin layer consists of 39% nylon 66 / 6, 60% nylon composition A and 1% anti-stick nylon masterbatch; the core layer consists of 37% nylon 6, 60% nylon composition B and 3% nylon secondary material Composition; The second skin consisted of 39% Nylon 6 / 66, 60% Nylon Composition A and 1% anti-stick nylon masterbatch.

[0046]Nylon composition A is composed of bio-based nylon 56, nylon 66 / 612 and maleic anhydride graft-modified polyether block amide copolymer, and the content ratio is 7:2.5:0.5.

[0047] Nylon composition B is composed of bio-based nylon 56, nylon 66 / 6 and glycidyl methacrylate graft-modified polyether block amide copolymer with a content ratio of 7:2:1.

[0048] Its preparation method is identical with embodiment 1.

Embodiment 3

[0050] A high-shrinkage biaxially oriented polyamide film with a thickness of 15 μm and a first skin layer and a second skin layer with a thickness of 1.8 μm.

[0051] The first surface layer is composed of 29% nylon 610, 70% nylon composition A and 1% anti-adhesive nylon masterbatch; the core layer is composed of 24% nylon 610, 75% nylon composition B and 1% nylon secondary material; The second skin layer consisted of 20% Nylon 610, 79% Nylon Composition A, and 1% release nylon masterbatch.

[0052] Nylon composition A is composed of bio-based nylon 56, nylon 66 / 612 and acrylic acid graft-modified polyether block amide copolymer, and the content ratio is 8:2.5:0.5.

[0053] Nylon composition B is composed of bio-based nylon 56, nylon 66 / 6 and glycidyl methacrylate graft-modified polyether block amide copolymer with a content ratio of 8:3:1.

[0054] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap