Preparation method of 4-hydroxymethyl coumarin compound

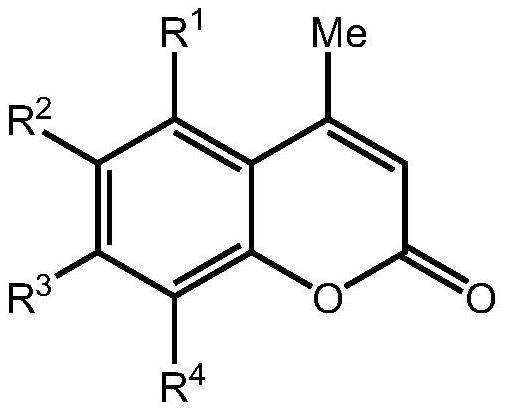

A technology of hydroxymethyl coumarin and methyl coumarin, which is applied in the field of preparation of 4-hydroxymethyl coumarin compounds, can solve the problem of not having industrial production value, practical production value, and reducing production Cost and other issues, to achieve the effect of efficient preparation, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

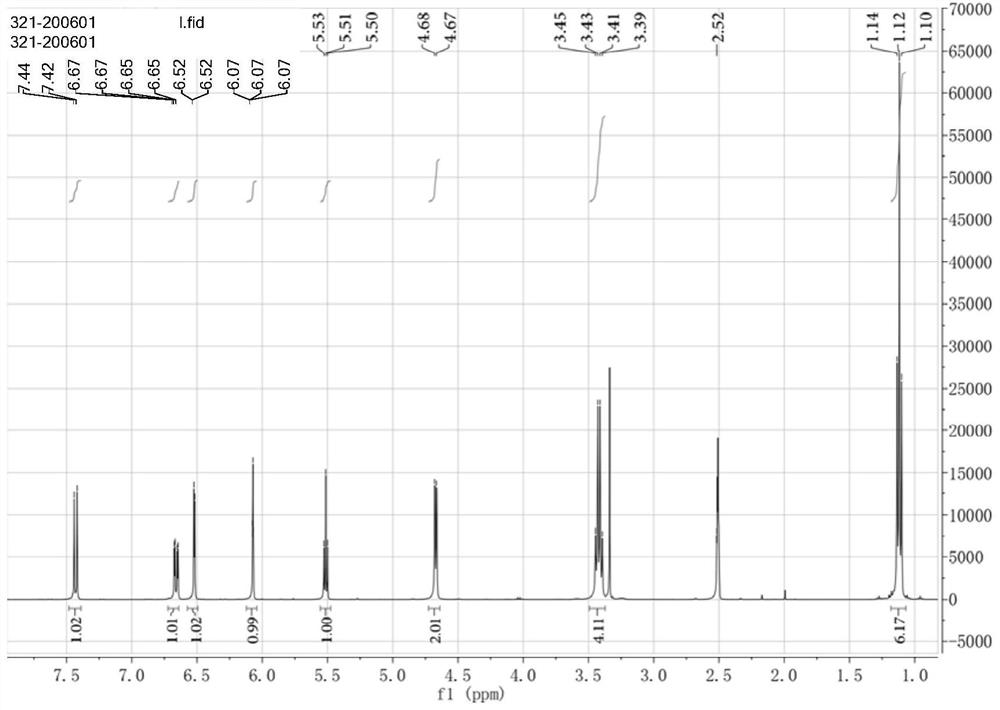

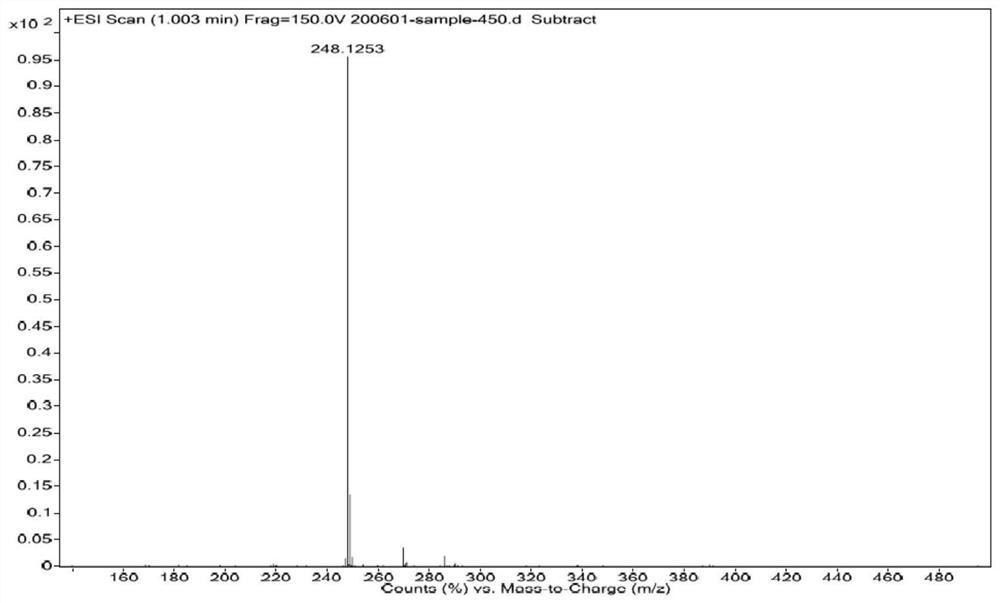

Image

Examples

Embodiment 1

[0031] Disperse 2kg of 7-diethylamino-4-methylcoumarin in 20L of toluene, add 3.2kg of benzoyl peroxide and 0.07kg of sodium acetate, and heat to reflux for 12 hours. After the reaction was finished, cool to room temperature, then filter and separate, and wash with 1 L of water each time for a total of 5 washes to collect the solid material to obtain an intermediate.

[0032] Disperse the obtained intermediate in 30L of water, add 1.8kg of sodium bisulfite, stir at room temperature for 16 hours, filter and separate the solid material and the water phase, disperse the solid material in 4L of ethyl acetate, heat to reflux, and cool to After standing at room temperature for 12 hours, it was separated by filtration again. After drying, 7-diethylamino-4-hydroxymethylcoumarin was obtained, weighing 1.54kg, and the yield was 72%.

[0033]The aqueous phase was extracted with ethyl acetate, 3 L each time, and extracted 4 times in total. The extract was mixed with the filtrate obtained by

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap