Catalyst and carrier with function of catalyzing alcohol to synthesize organic amine through hydrogen ammoniation and preparation method and application of catalyst and carrier

A hydrogenation ammonia and catalyst technology, applied in the field of ammonification reaction, can solve the problem of low catalytic activity and achieve the effects of accelerating reaction rate, slowing down pore blockage and excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] According to the present invention, the carrier can be prepared by using an existing method that can obtain the ammonia adsorption amount and pore structure and the like that meet the above ranges, and obtaining the carrier with the ammonia adsorption amount and the pore structure meeting the above ranges is a matter for those skilled in the art according to the present invention. implementable. However, according to a preferred embodiment of the present invention, the carrier is prepared by a method comprising the following steps: forming the precursor containing doping elements, the mixture of pseudo-boehmite and optional other carrier sources in sequence; Drying and roasting, the other carrier source is selected from at least one of silicon oxide precursors (such as silica sol), molecular sieve precursors (such as ZSM-5) and diatomite precursors, and the roasting temperature is 800- 1050°C. The molding method can use kneading, rolling, or sheeting.

[0029] In the abo

Example Embodiment

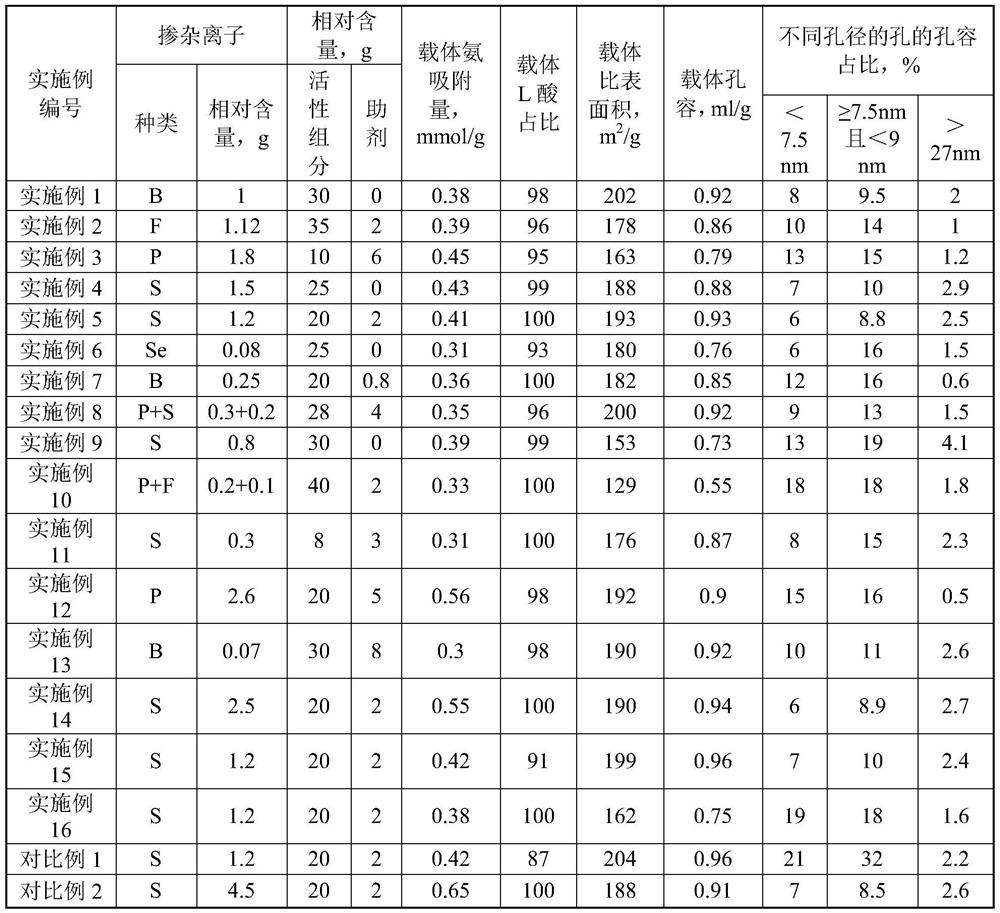

[0056] Example 1

[0057] The pseudo-boehmite powder (specific surface area 315m 2 / g, pore volume 0.91ml / g) kneaded with dilute acid water containing nitric acid and boric acid, extruded into strips with a diameter of 5mm, cut into 4mm lengths, dried at 100 ° C for 10 hours, and then roasted at 850 ° C for 4 hours. The required carrier and the amount of boric acid adjusted to achieve the boron element content in the carrier are shown in Table 1.

[0058] 151.2g of cobalt nitrate hexahydrate (industrial grade, purity 98%) was dissolved in water into 184mL solution, and the solution was loaded on the obtained 100g carrier by spray dipping method in two times, and dried at 120°C after each spray dipping method for 4 hours, then calcined at 400 °C for 4 hours, and then gradually heated and reduced with hydrogen at a rate of 20 °C / hour, and finally reduced at 430 °C for 3 hours to obtain catalyst C-1. The grain size of the loaded component was determined by XRD (see Test Exam

Example Embodiment

[0059] Example 2

[0060] In the kneader, the pseudo-boehmite powder (specific surface area 322m 2 / g, pore volume 0.93ml / g), add silica sol (JN-40, Qingdao Ocean Chemical Co., Ltd.), mix evenly, knead with dilute acid water containing nitric acid and hydrofluoric acid, extrude into a 3mm thick clover shape, in the After drying at 120 °C for 6 h, and then calcining at 820 °C for 3.5 h, the desired carrier was prepared. Adjust the amount of silica sol JN-40 to achieve Al in the carrier 2 O 3 quality with SiO 2 The mass ratio is 9:1.

[0061] Dissolve 177g of nickel nitrate hexahydrate (technical grade, purity 98%) into 172mL solution with water, and dissolve 3.7g of ammonium molybdate tetrahydrate (analytical grade) into 86ml solution with water; the nickel nitrate solution is loaded by spray dipping method in two times. On the obtained 100g carrier; the ammonium molybdate solution was supported on the carrier again by spray dipping method, and after each spray dipping me

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap