Load test device and method for test pile

A technology of load test and test device, which is applied in the test of foundation structure, sheet pile wall, building, etc., can solve the problems of time-consuming, labor-intensive and material-consuming to assemble and disassemble steel bars, and achieve flexible and changeable devices and methods, and simple and quick disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

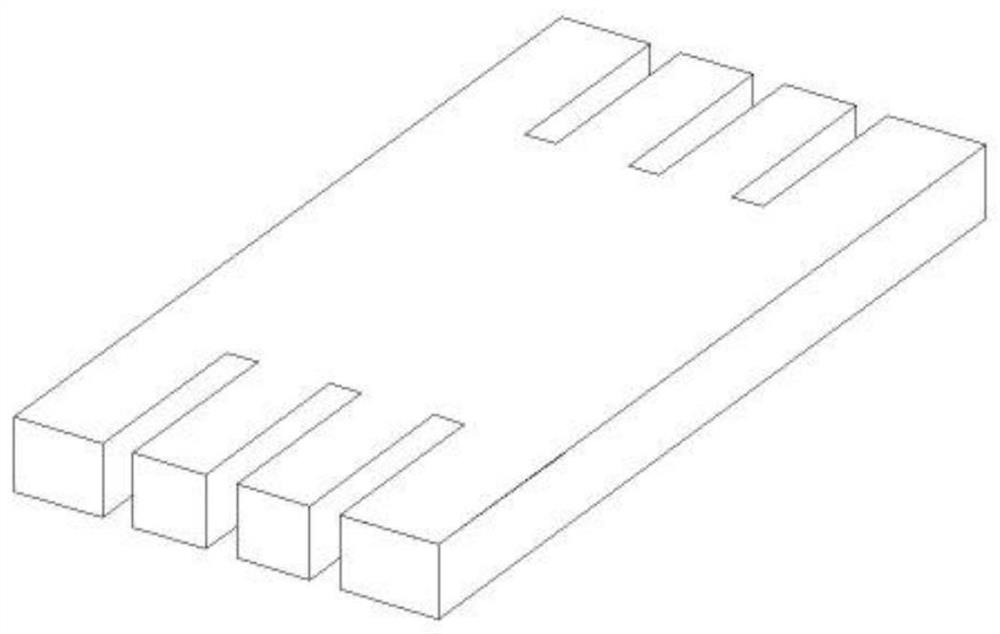

[0031] The invention describes a load test device for a test pile, comprising an anchor pile beam arranged on the test pile, and anchor plates symmetrically placed at both ends of the anchor pile beam, such as figure 1 As shown in the figure, the anchor plate includes a body, and the opposite ends of the body are symmetrically provided with a plurality of limit slots; the test device also includes a plurality of anchors and a plurality of anchor cables, and one end of the anchor cables penetrates the anchors and the limit grooves. Slots are used to fix the anchor to the anchor plate to provide vertical pressure to the test pile. The invention utilizes the anchor plate and the anchor to fix the anchor cable, and provides the vertical pressure to the test pile through the anchor pile beam, thereby

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap