Composite manganese oxide catalyst for synchronously removing VOCs (Volatile Organic Compounds) and NOx in medium and low temperature flue gas as well as preparation method and application of composite manganese oxide catalyst

A technology of low-temperature flue gas and manganese oxides, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve problems such as the inability to simultaneously remove VOCs and NOx , to achieve excellent VOCs and NOx simultaneous removal efficiency, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

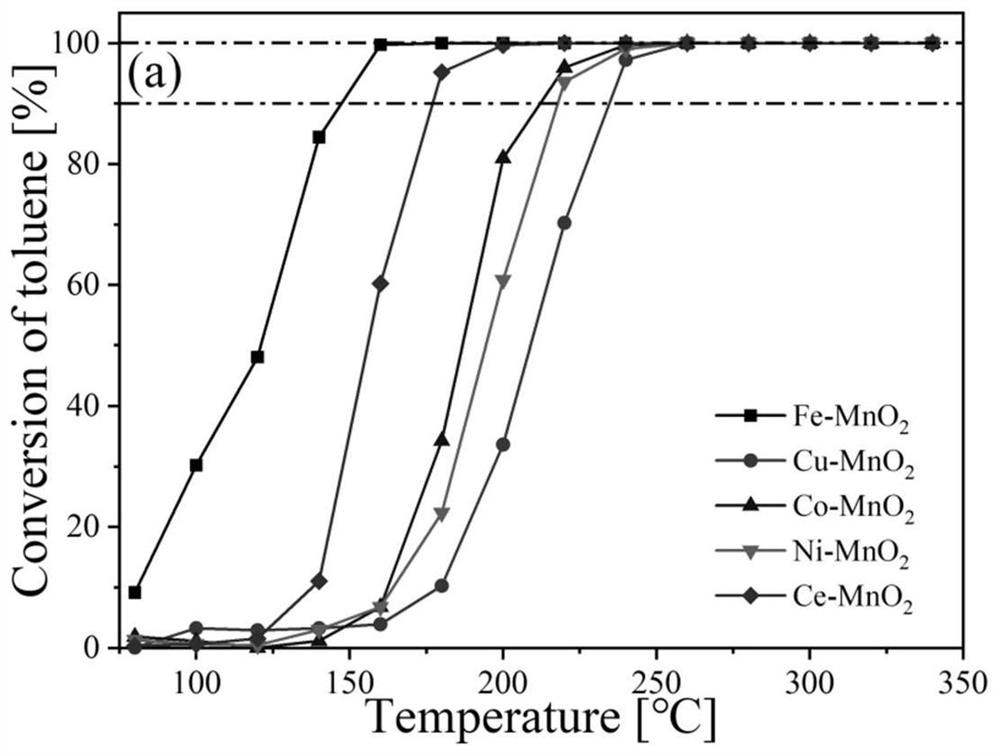

Embodiment 1

[0024] (1) Precursor gel configuration

[0025] According to the molar ratio of n(Fe):n(Mn)=1:2 in the final sample, weigh the iron nitrate (Fe(NO) 3 ) 3 ) was added to deionized water, dispersed with ultrasound and stirred at room temperature for 1 h until fully dissolved to form a precursor solution. Potassium permanganate (KMnO 4 ) was quickly added to the precursor solution with constant stirring to form a uniform and stable compound.

[0026] (2) High pressure crystallization

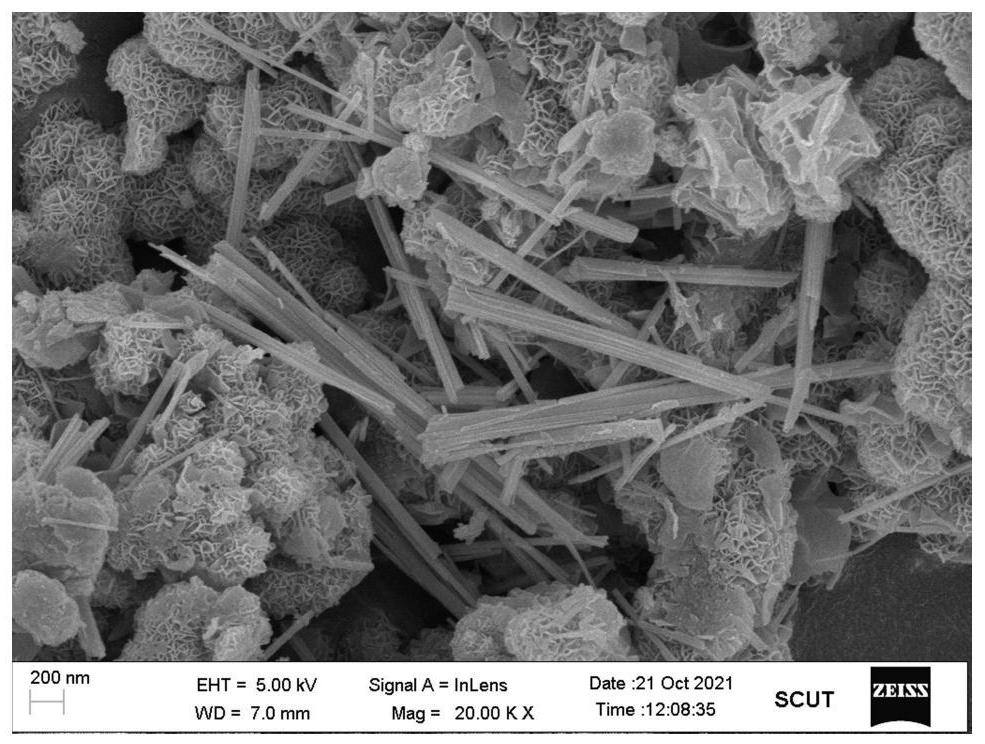

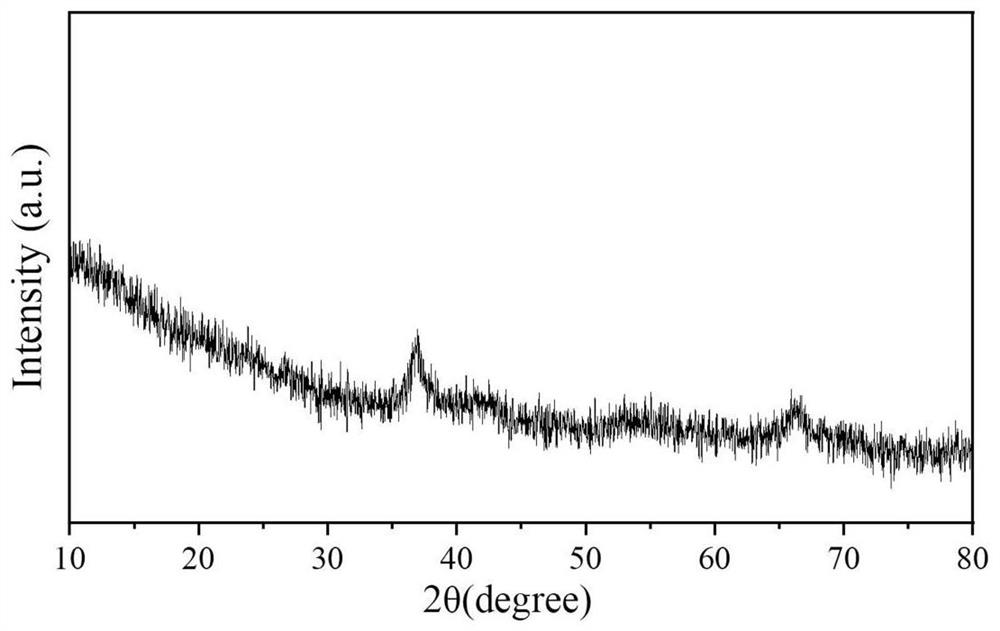

[0027] The obtained solution was transferred to a polytetrafluoroethylene liner, placed in a stainless steel reaction kettle, and left to stand at 120° C. and autogenous pressure for 24 hours to form crystals. After the reaction was completed, the reaction kettle was taken out and cooled at room temperature. The obtained crystalline product was repeatedly washed with deionized water, dried at 80°C overnight, and rolled and screened to obtain the synchronous VOCs and NOx used in medium and low temp

Embodiment 2

[0033] (1) Precursor gel configuration

[0034] According to the molar ratio of n(Cu):n(Mn)=1:2 in the final sample, weigh copper nitrate (Cu(NO) 3 ) 2 ) was added to deionized water, dispersed with ultrasound and stirred at room temperature for 1 h until fully dissolved to form a precursor solution. Potassium permanganate (KMnO 4 ) was quickly added to the precursor solution with constant stirring to form a uniform and stable compound.

[0035] (2) High pressure crystallization

[0036] The obtained solution was transferred into a polytetrafluoroethylene liner, placed in a stainless steel reaction kettle, and allowed to stand at 100° C. and autogenous pressure for 24 hours to form crystals. After the reaction was completed, the reaction kettle was taken out and cooled at room temperature. The obtained crystalline product was repeatedly washed with deionized water, dried at 90°C overnight, and rolled and screened to obtain the synchronous VOCs and NOx used in medium and low t

Embodiment 3

[0040] (1) Precursor gel configuration

[0041] According to the molar ratio of n(Co):n(Mn)=1:2 in the final sample, weigh cobalt nitrate (Co(NO) 3 ) 2 ) was added to deionized water, dispersed with ultrasound and stirred at room temperature for 1 h until fully dissolved to form a precursor solution. Potassium permanganate (KMnO 4 ) was quickly added to the precursor solution with constant stirring to form a uniform and stable compound.

[0042] (2) High pressure crystallization

[0043] The obtained solution was transferred into a polytetrafluoroethylene liner, placed in a stainless steel reaction kettle, and allowed to stand at 100° C. and autogenous pressure for 24 hours to form crystals. After the reaction was completed, the reaction kettle was taken out and cooled at room temperature. The obtained crystalline product was repeatedly washed with deionized water, dried at 90°C overnight, and rolled and screened to obtain the synchronous VOCs and NOx used in medium and low t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap