Novel FeCrMnVSix high-entropy alloy coating and preparation method thereof

A high-entropy alloy and coating technology, applied in the direction of metal material coating process and coating, can solve the problems of uneven composition and structure, uneven structure, cracks and pores, etc., to broaden the application direction and promote the lattice The degree of distortion and the effect of enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The FeCrMnVSix (x=0) high-entropy alloy powder ratio is carried out according to the molar ratio: Fe 25%, Cr 25%, Mn 25%, V 25%, and each metal powder is weighed by an electronic balance.

[0038] The sources of each metal element powder are listed in the table below

[0039]

[0040]

[0041] (2) The pretreatment process of the substrate is as follows: the metallographic grinding and polishing machine grinds the cladding surface of the substrate 410 steel (1Cr13) to 800# to achieve the purpose of removing oxides on the surface of the substrate, and then cleans it with ethanol and puts it into a vacuum oven for use. .

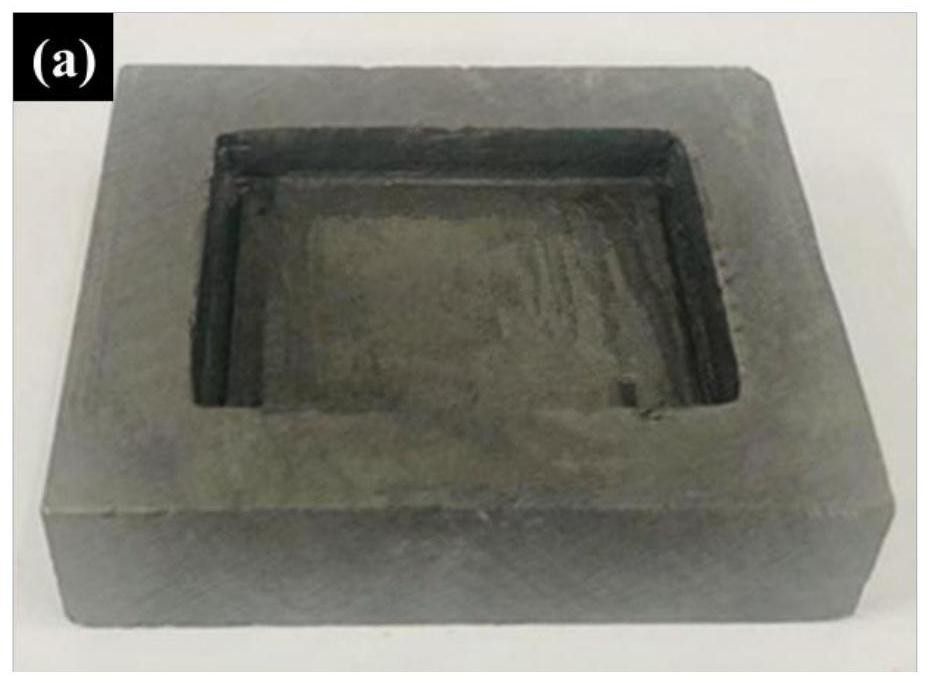

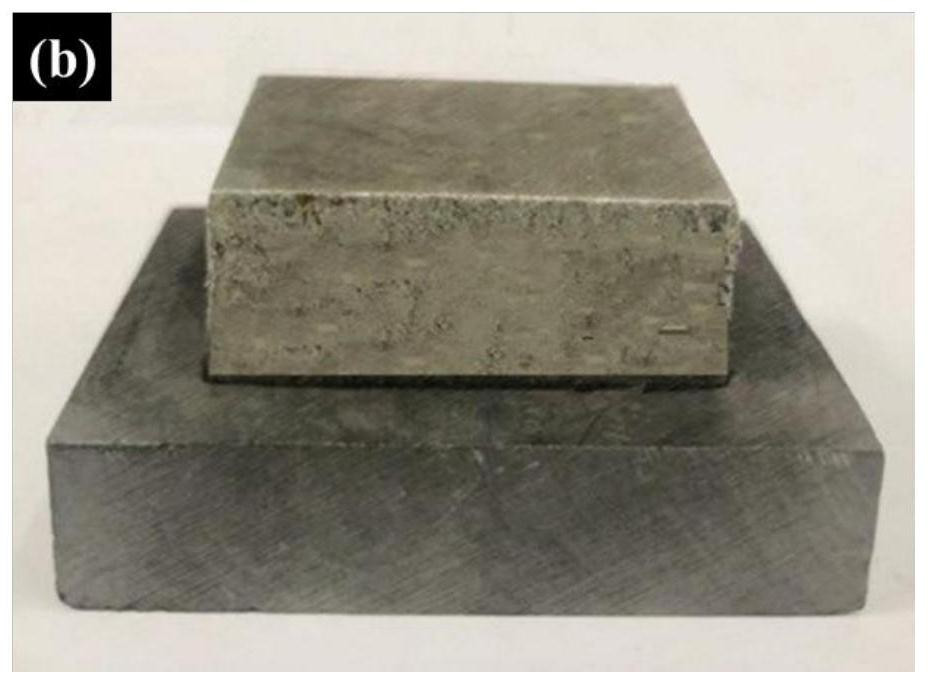

[0042] (3) After drying the metal powder weighed in step (1), spread it on a surface such as figure 1 In the mold, the substrate processed in step (2) is embedded in the mold and compacted, such as figure 2 As shown, a prefabricated high-entropy alloy powder layer is formed on the surface of the substrate, and the thickness of the prefabricated

Embodiment 2

[0050] The difference in this example from Example 1 is: (1) In accordance with the molar ratio, FeCrMnVSix (x=0.5) high-entropy alloy powder ratio: Fe 22.2%, Cr 22.2%, Mn 22.2%, V 22.2%, Si 11.2 %; (4) the scanning speed is 5mm / s. The rest of the operation process and parameter setting are the same as in Example 1, and a FeCrMnVSi x (x=0.5) high-entropy alloy coating is obtained, which is referred to as FeCrMnVSi0.5 for short.

[0051] Characterization and Testing:

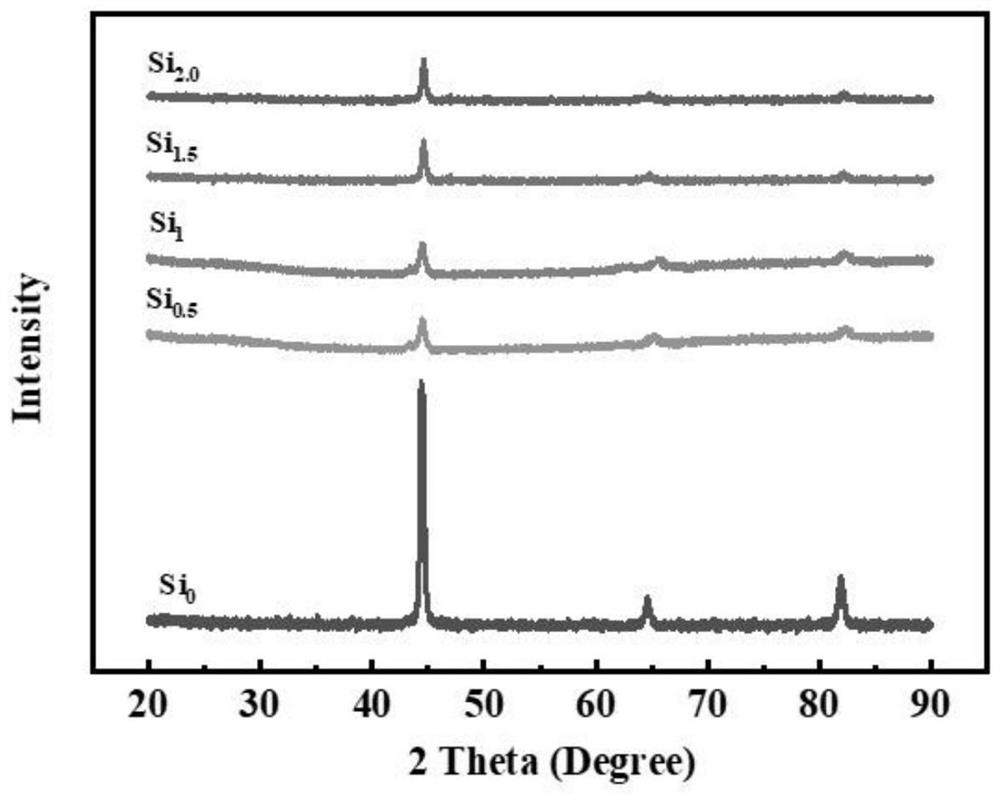

[0052] ①XRD test, the results are as follows image 3 Medium Si 0.5 As shown in the curve, it is proved that the obtained coating is a high-entropy alloy, and the high-entropy alloy coating FeCrMnVSi0.5 is a single solid solution phase.

[0053] ②Hardness test, the microhardness of the laser cladding high-entropy alloy coating was measured by a digital display hardness tester. The results are as follows Figure 5 (a) Si 0.5 curve and Figure 5 As shown in (d), the average hardness of the alloy coating is 329

Embodiment 3

[0056] The difference in this example from Example 1 is: (1) FeCrMnVSi is carried out according to the molar ratio 1 (x=1) High-entropy alloy powder ratio: Fe 20%, Cr 20%, Mn 20%, V 20%, Si 20%; (4) The scanning speed is 5 mm / s. The rest of the operation process and parameter setting are the same as in Example 1, and a FeCrMnVSix (x=1) high-entropy alloy coating is obtained, which is referred to as FeCrMnVSi1 for short.

[0057] Characterization and Testing:

[0058] ①XRD test, the results are as follows image 3 Medium Si 1 As shown in the curve, it is proved that the obtained coating is a high-entropy alloy, and the high-entropy alloy coating FeCrMnVSi1 is a single solid solution phase.

[0059] ②SEM test, results Figure 4 shown, by Figure 4 It can be seen that the high-entropy alloy coating is dense, almost free of cracks and pores, and the alloy is of high quality, and the EDS characterization results show that the distribution of alloy elements is uniform.

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap