Application of conductive thermosetting resin composition

A resin composition, thermosetting technology, applied in conductive adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of light-emitting components not emitting light, adhesive discoloration, resistance value changes, etc., Achieve low stress, enhanced adhesion, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

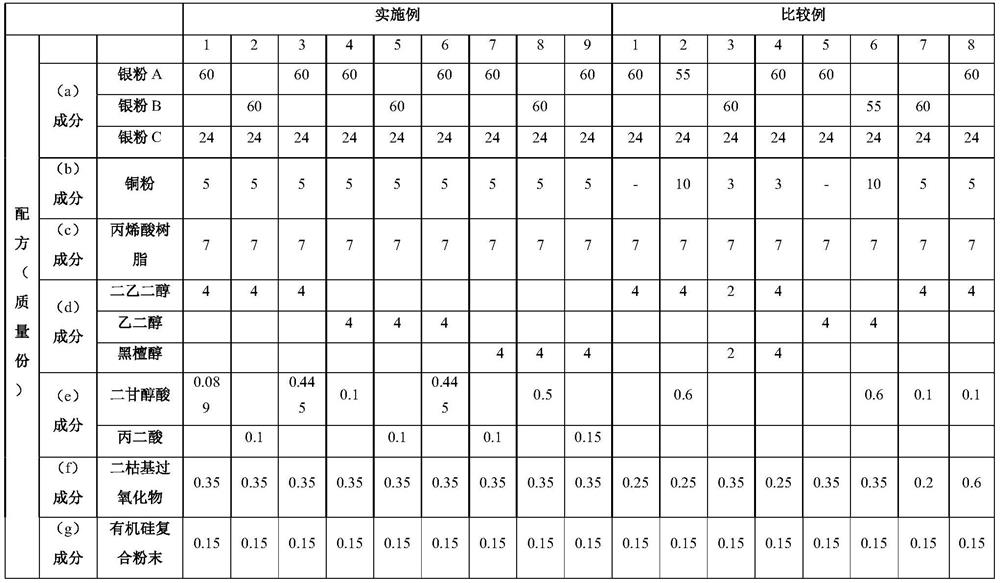

[0043] In the examples and comparative examples involved in the present invention, at first the acrylic resin and (f) free radical initiator were mixed according to the ratios in Table 2, and after the (f) component was completely dissolved, it was marked as XEY for later use, and then the raw material Mix according to the ratio in Table 2, put it on the mixer and stir evenly, use a three-roller machine for mixing or a planetary high-mixer to mix, and after all the raw materials are fully dispersed and uniform, a conductive thermosetting resin composition preform is obtained, referred to as a silver glue preform ;

[0044] Then add the configured XEY to the silver colloidal pre-product for defoaming and viscosity adjustment, adjust the viscosity to 5rpm 8.0-9.0pa·s, and then the finished silver colloid can be obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap