Level bubble grinding machine

A grinding machine and leveling bubble technology, applied in the field of grinding machines, can solve the problems of high skill requirements of workers, low product efficiency, uneven quality, etc., and achieve the effects of low technical requirements of workers, high grinding precision and good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

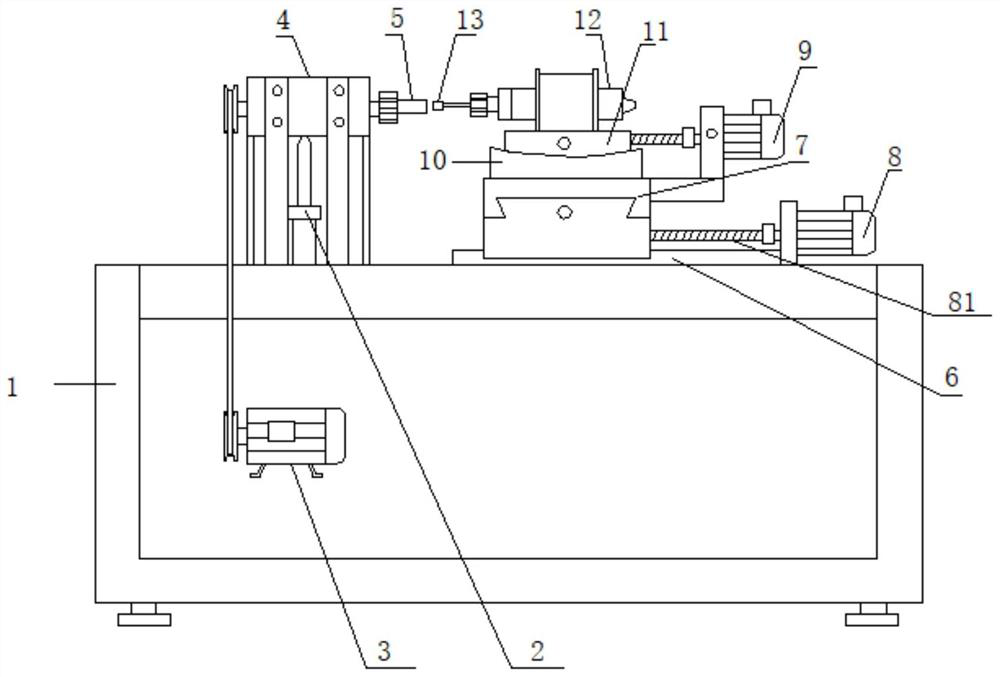

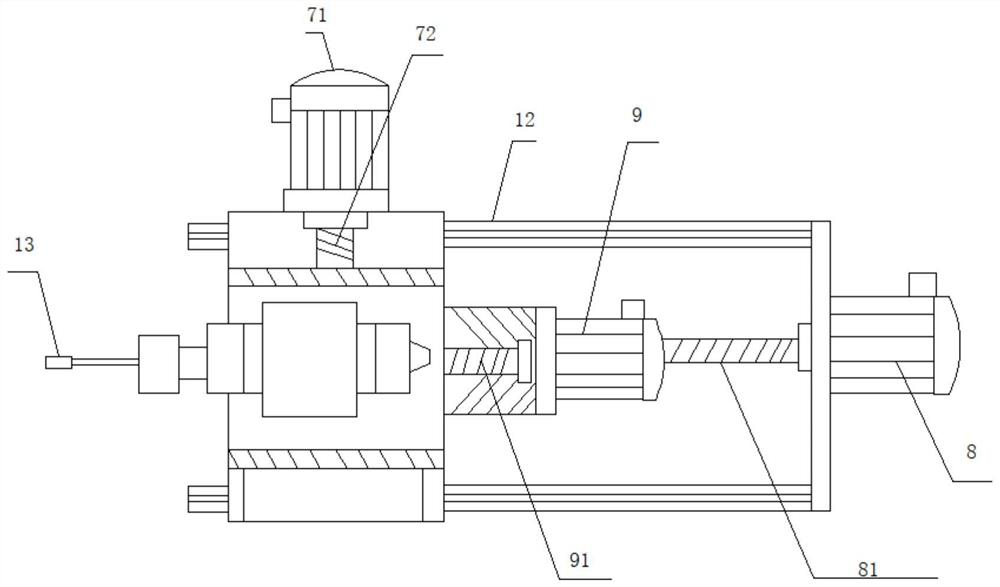

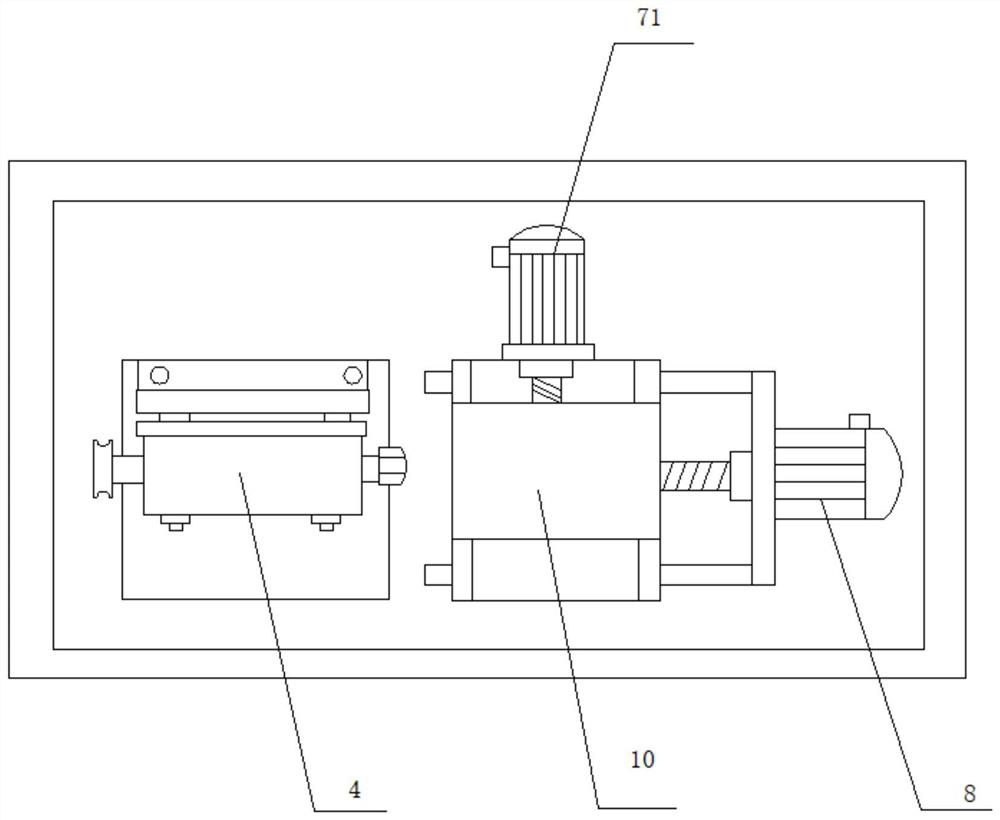

[0026] refer to figure 1 and Figure 5 , a level bubble grinding machine, including a body 1 and a circulating grinding liquid mechanism and a PLC control mechanism arranged on the body 1, the top of the body 1 is rotatably installed with a main shaft 4, the rotational speed of the main shaft 4 is 200r / min, on the body 1 There is a main shaft motor 3, the output shaft of the main shaft motor 3 is connected with the main shaft 4 in a driving manner, a pulley 1 is fixed on the output shaft of the main shaft motor 3, a belt pulley 2 is fixed on the main shaft 4, and the belt pulley 1 and the belt pulley 2 are connected by a belt drive. , start

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap