High power LED array module

A technology of light-emitting diodes and array modules, which is applied to semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of poor luminous effect, reduced luminous efficiency, and small surface area of array modules, so as to improve heat dissipation efficiency and Optical coupling performance, simplified packaging process, and improved power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

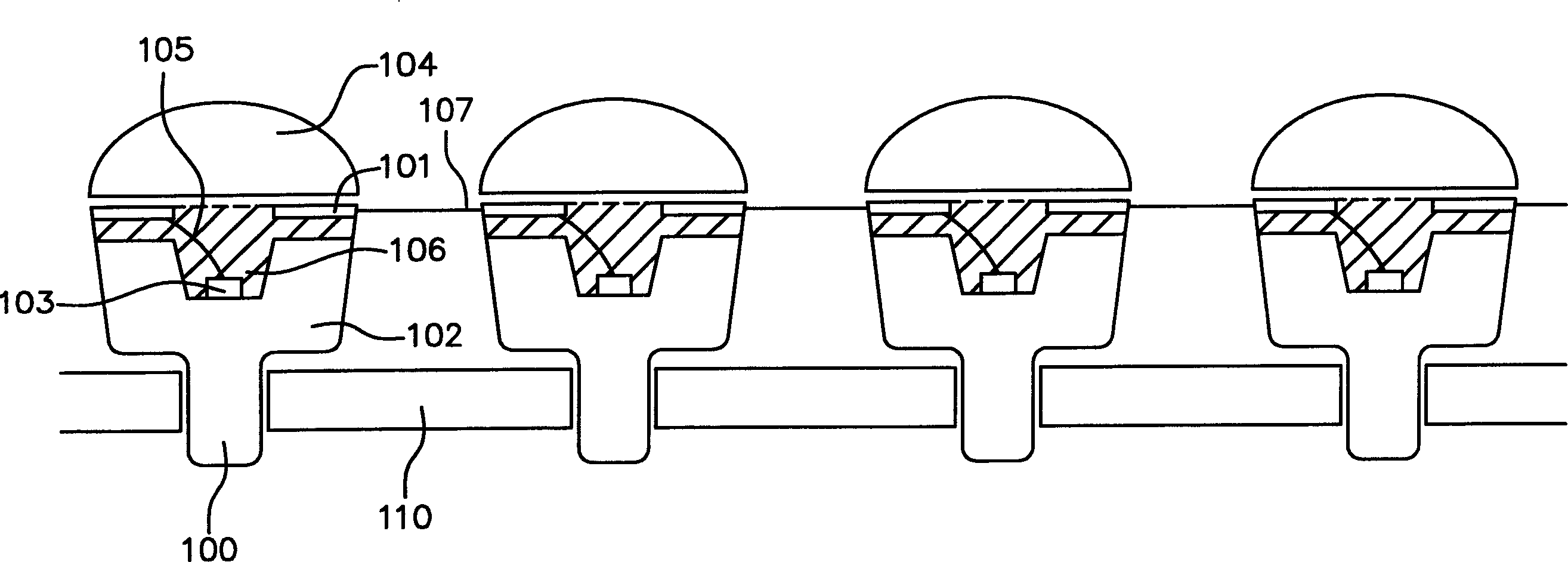

[0036] The high-power light-emitting diode array module of the present invention uses a circuit board with a plurality of placement holes to directly place high-power light-emitting diode chips into the placement holes for packaging. In this way, the volume of the array module can be greatly reduced. By configuring the heat dissipation structure in the circuit board, the heat dissipation efficiency can be significantly improved. Additionally, the lens on each placement hole can be adjusted for the array module to optimize the beam output.

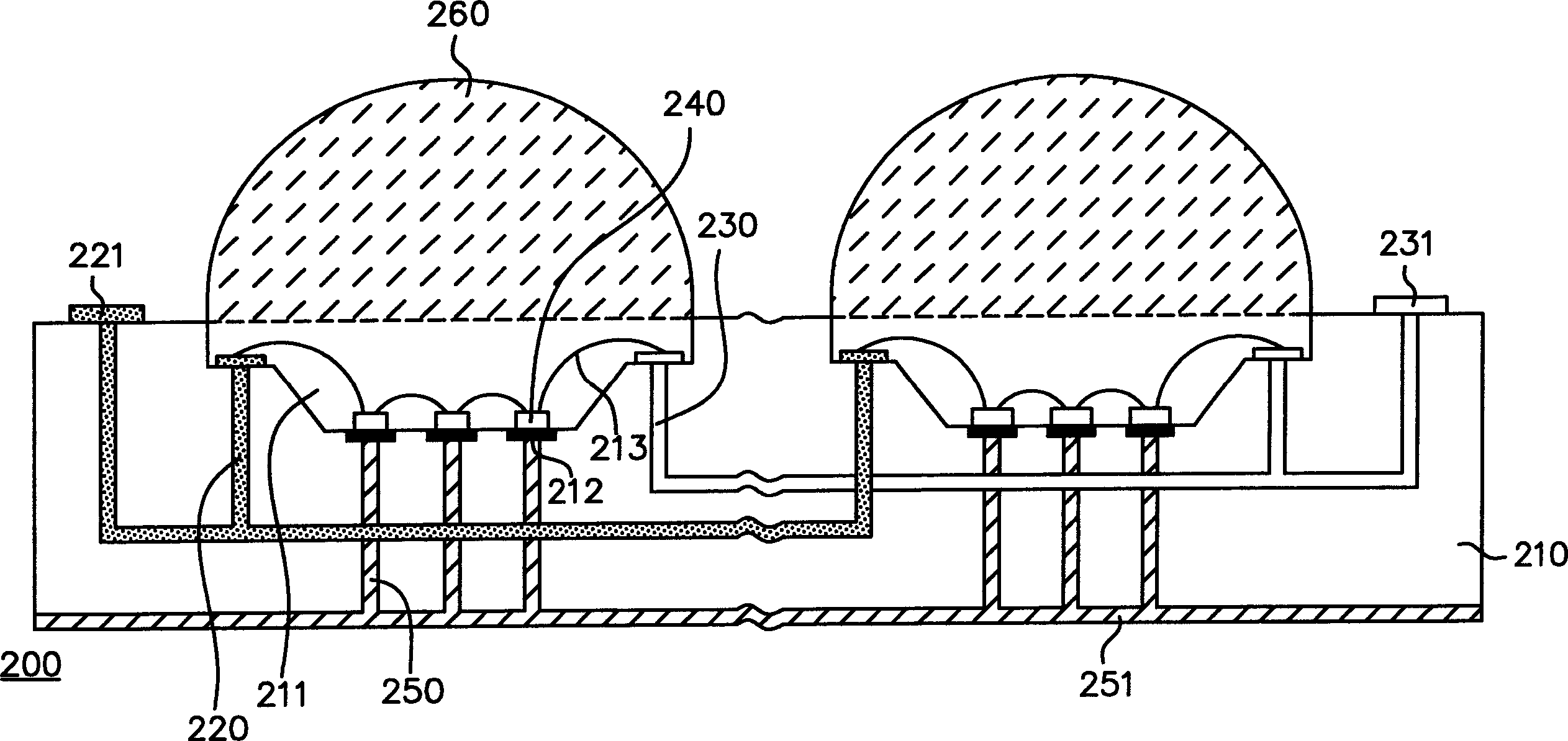

[0037] figure 2 It is a cross-sectional view of the high-power light-emitting diode array module in the first preferred embodiment of the present invention. The high-power LED array module 200 of the present invention includes a circuit board 210 , an anode 220 , a cathode 230 , a high-power LED chip 240 , a heat dissipation structure 250 , and a lens 260 .

[0038] The circuit board 210 has a plurality of placement holes 211 arranged i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap