Dissolved oxygen electrode

A technology of dissolved oxygen electrode and electrode core, which is applied to electrochemical variables of materials, material analysis by electromagnetic means, measurement devices, etc. Short time, high stability and reproducibility, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

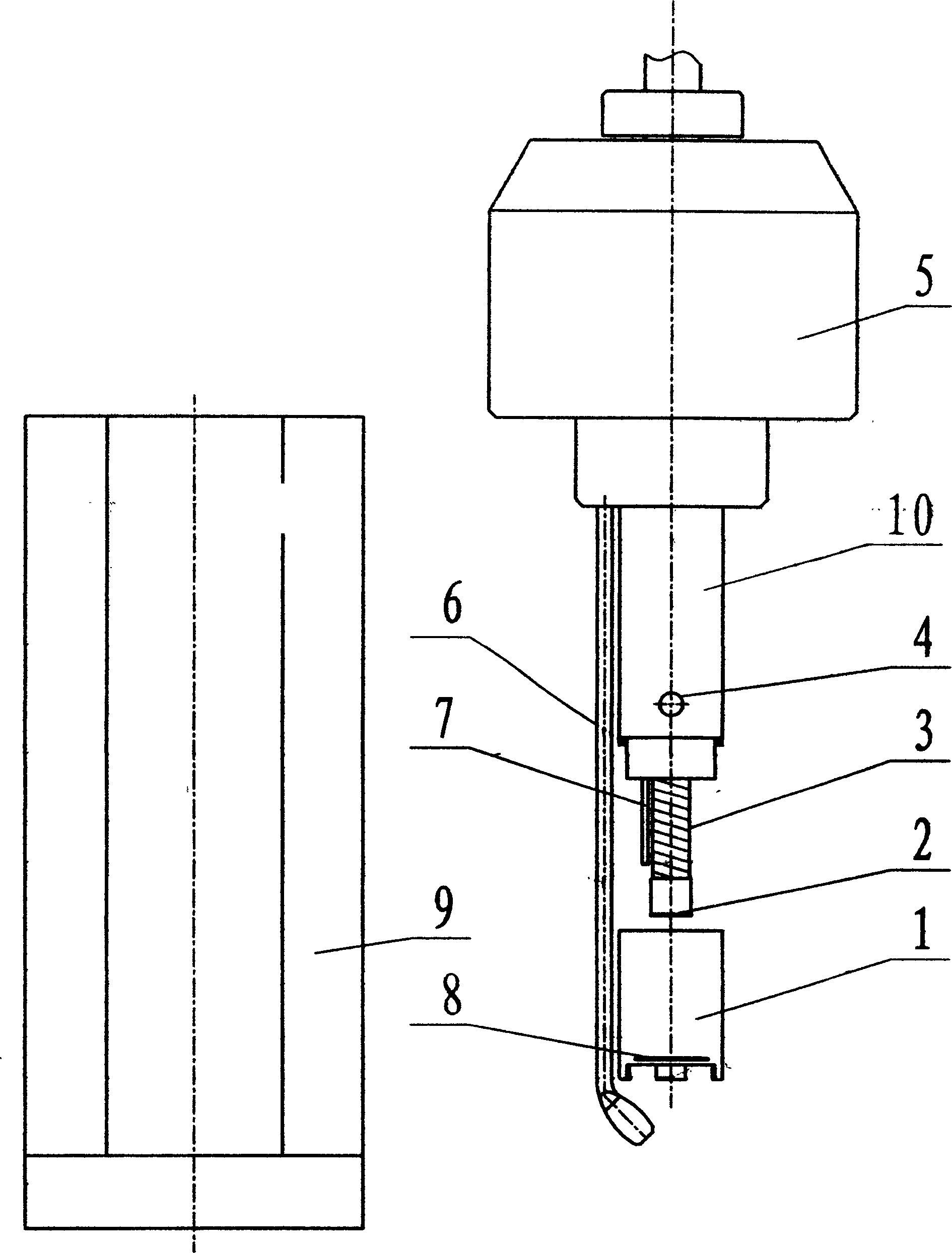

[0009] according to figure 1 As shown, a dissolved oxygen electrode is mainly composed of a working electrode 2, a silver-silver chloride reference electrode 3 and an auxiliary electrode 7. The upper ends of the three electrodes are connected to the electrode lead wires. The working electrode 2 is metallic gold, and the metallic gold is encapsulated by the polyether ether ketone electrode core 10. The electrode core 10 is a stepped cylinder, the lower end is the thinnest, the middle part is slightly thicker, and the upper part is the thickest. The working electrode 2 is wrapped around the thinnest part of the electrode core 10 and a part is exposed outside the electrode core 10. The reference electrode 3 surrounds the surface of the electrode core 10 with the working electrode 2. An auxiliary electrode 7 is installed in the slightly thicker middle of the electrode core 10, and the auxiliary electrode 7 extends out of the electrode core 10 and is arranged in parallel with the working

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap