Process of producing porous water-permeable construction material using ingredient from matter combustion

A technology for building materials and substances, applied in the removal of solid waste, manufacturing tools, ceramic molding machines, etc., can solve the problems of easily polluted water sources, structural changes in road areas, and urgency, and achieve the effect of reducing manufacturing costs and low costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

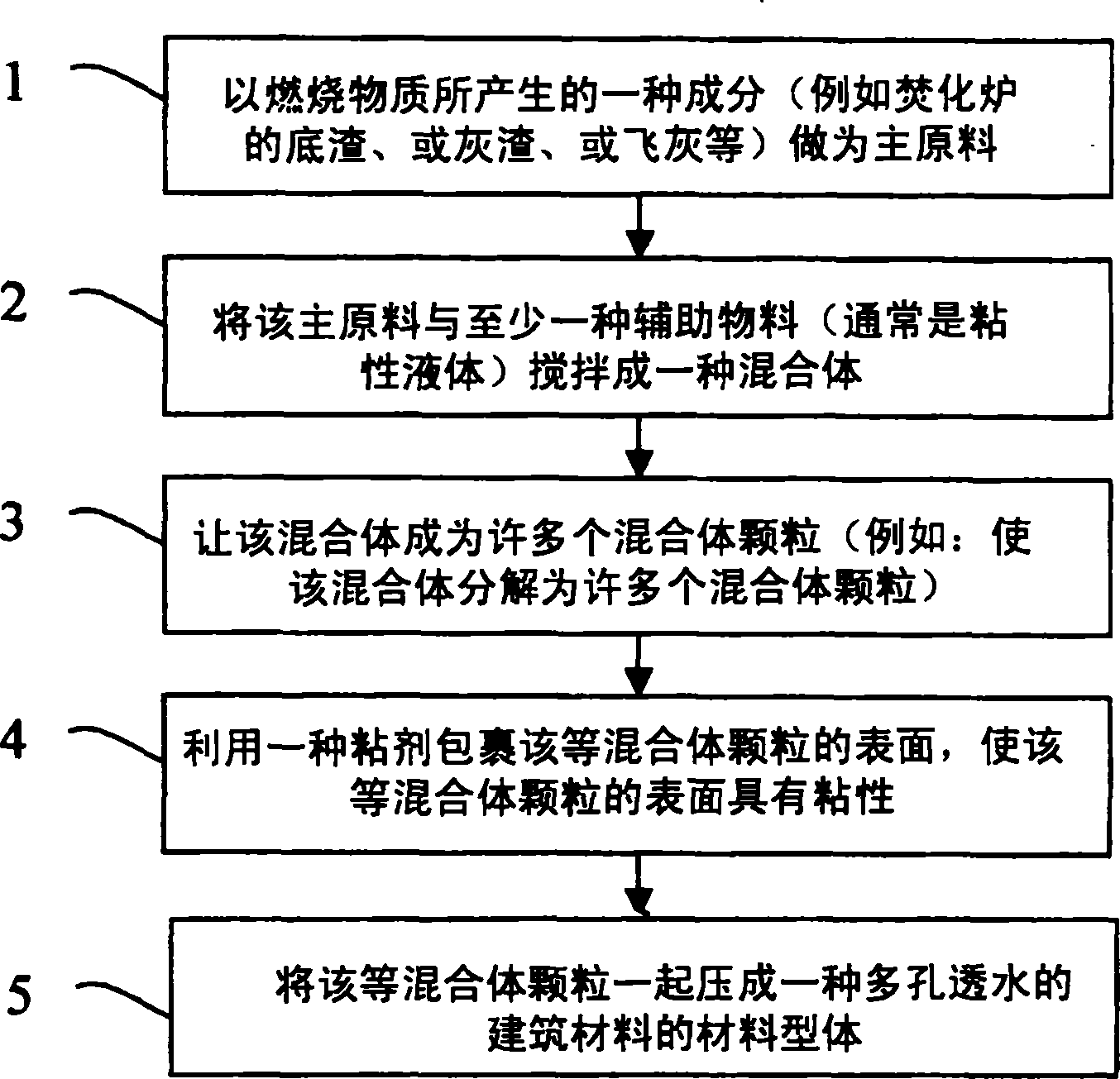

[0056] The process for producing the porous and water-permeable building material by the composition of the combustion substance of the present invention is used to make a porous and water-permeable building material. The porous and water-permeable building material has a material shape. The combustion substance of the present invention A first representative example of a process for producing porous and water permeable building materials from the resulting components is shown in figure 1 shown, including:

[0057] The first step is to use a component produced by burning substances (such as bottom slag, or ash, or fly ash, etc. of an incinerator) as the main raw material;

[0058] Step 2, stirring the main material and at least one auxiliary material (usually a viscous liquid) into a mixture;

[0059] Step 3, let the mixture become many particles (for ease of explanation, the present invention refers to these particles as "mixture particles"), for example: utilize mechanical vib

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap