Pressure-sensitive adhesive sheet for exterior portion of vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

Example 1

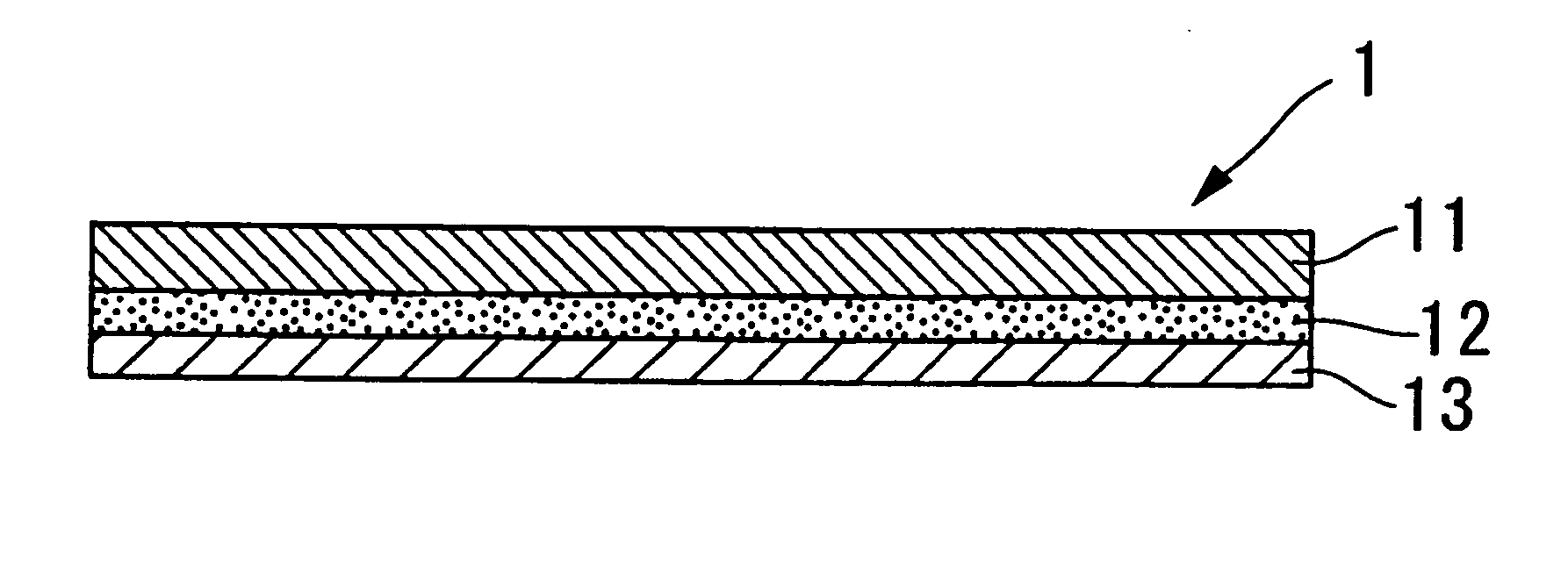

[0042] A solvent type acrylic pressure-sensitive adhesive containing an acrylic acid as a monomer unit (made by LINTEC Corporation, SK) was applied using a knife coater such that the thickness after drying would be 40 μm onto the release treated surface of release paper (made by OJI PAPER CO., LTD., SP-12HL, thickness: 170 μm) obtained by subjecting polyethylene-laminated paper to release treatment with a silicone type release agent, and drying was carried out for 1 minute at 90° C. A 100 μm-thick polyurethane film (made by SEIKOH CHEMICALS CO., LTD., LUCKSKIN FT80-100BK14) as a substrate was superposed onto the pressure-sensitive adhesive layer thus formed, whereby a pressure-sensitive adhesive sheet was obtained.

Example

Example 2

[0043] A pressure-sensitive adhesive sheet was produced as in Example 1, except that the substrate used was one obtained by adding 5 parts by mass of a crosslinking agent (made by NIPPON POLYURETHANE INDUSTRY CO., LTD., Coronate HL, solid content 5 mass %) to 100 parts by mass of a polyurethane resin (made by SEIKOH CHEMICALS CO., LTD., LUCKSKIN U-7480, solid content 15 mass %) to obtain a coating liquid, applying the coating liquid using a bar coater such that the thickness after drying would be 1 μm onto the pressure-sensitive adhesive layer-contacting surface of a 100 μm-thick polyurethane film (made by SEIKOH CHEMICALS CO., LTD., LUCKSKIN FT80-100BK14), and drying for 5 minutes at 80° C. so as to form a primer layer, and the pressure-sensitive adhesive layer was superposed onto the primer layer surface of the substrate.

Example

Example 3

[0044] A pressure-sensitive adhesive sheet was produced as in Example 1, except that a polyolefin type resin laminated film (made by MITSHBISHI CHEMICAL MKV COMPANY, ARTPLY CT030, thickness: 100 μm) having a 2 μm-thick weather-proof colored coating layer on a surface thereof was used as the substrate, and the pressure-sensitive adhesive layer was superposed onto the surface of the substrate on the opposite side to the weather-proof colored coating layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap