Photo-imaging Hardmask with Negative Tone for Microphotolithography

a microphotolithography and negative tone technology, applied in the field of microphotolithography, can solve the problems of difficult, if not impossible, inability to convert polysiloxane or polysilsesquioxane coatings into dielectric layers with trenches and vias, and achieve the effect of soluble or dispersibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

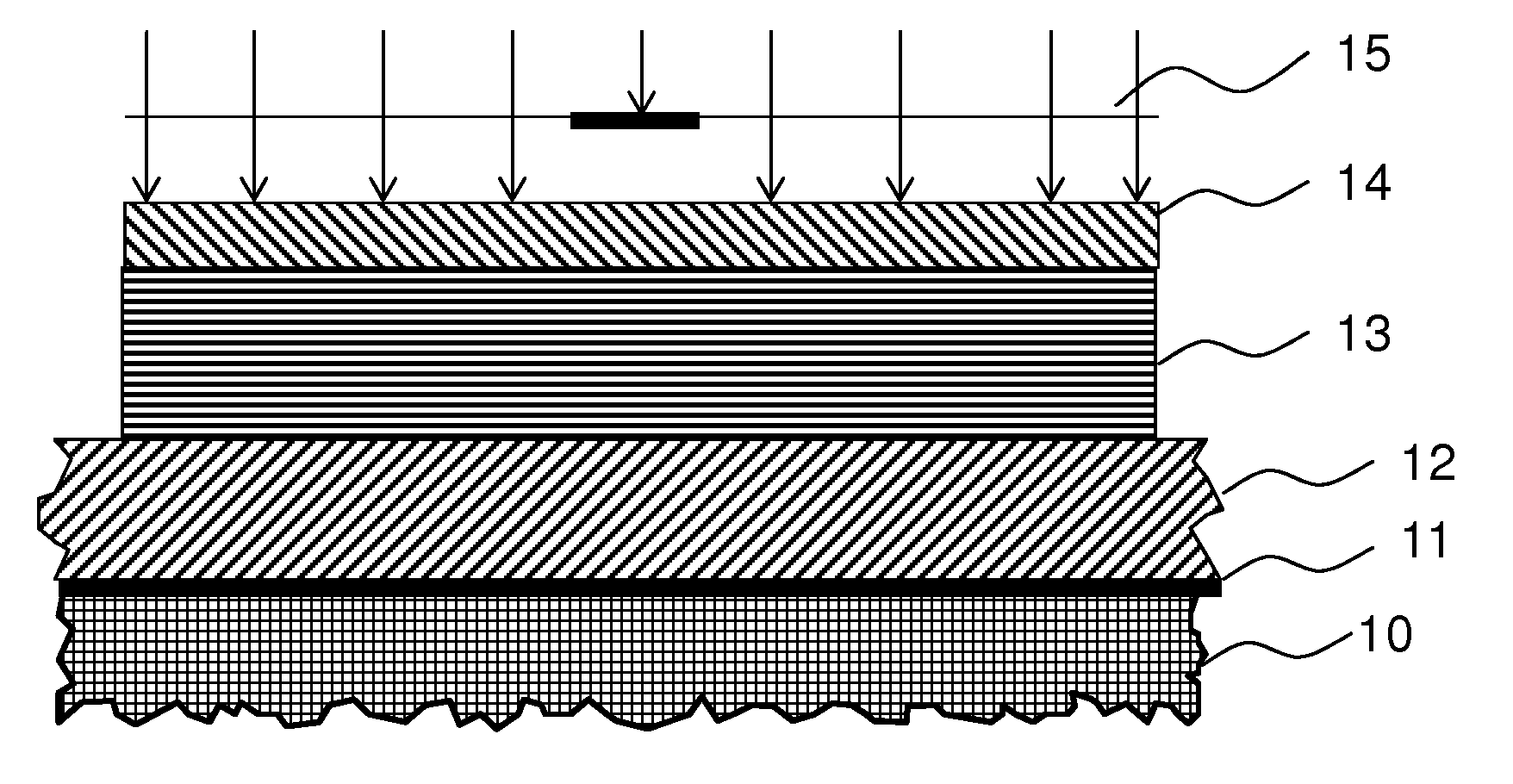

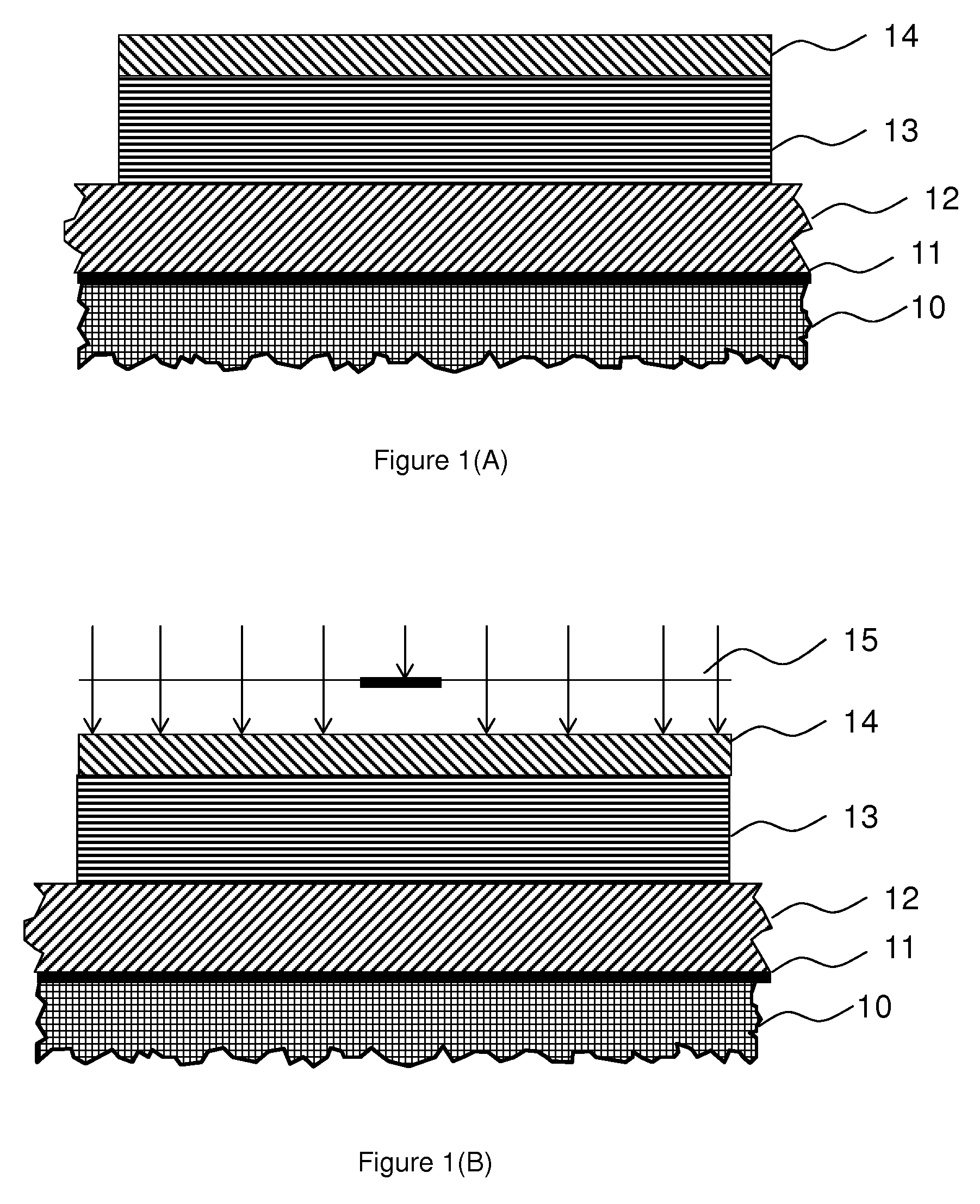

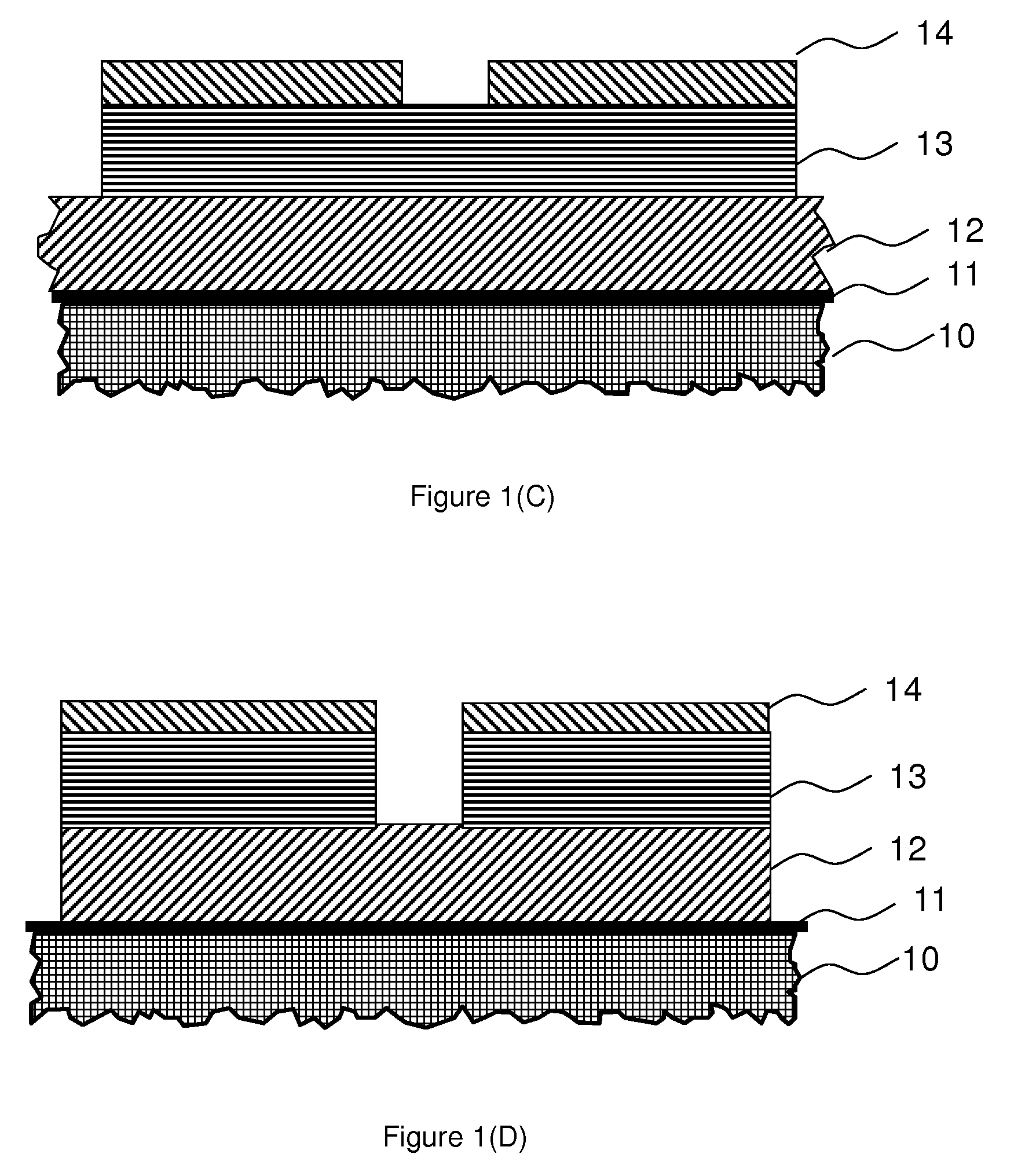

Image

Examples

example 1

Synthesis of Polysiloxane and Polysilsesquioxane Resin I

[0081]

TABLE 1Monomers for Polysiloxane and Polysilsesquioxane Resin I:Methyl trimethoxy silane (Gelest, Morrisville, PA)65.2 gramsTetraethoxy silane (Gelest, Morrisville, PA)26.6 gramsPhenyl trimethoxy silane (Gelest, Morrisville, PA)5.06 grams2-(3,4-Epoxycyclohexyl)ethyl trimethoxy silane1.57 grams(Gelest, Morrisville, PA)

[0082]Monomers in Table 1, together with 80 grams of propylene glycol methyl ether acetate (from Sigma Aldrich (Milwaukee, Wis.)), were mixed in a 500-mL three-neck round-bottom flask. Attached to the flask were distillation condenser, thermometer, and nitrogen inlet. Nitrogen flow was set at 200 milliliters per minute. With stirring, temperature of the mixture in the flask was raised to 95° C. in oil bath. Then, 50 grams of 3-nomal acetic acid were slowly added to the flask. Condensation reactions began. Volatile byproducts were distilled out of the flask and collected. Distillation completed in four hours. Hea

example 2

Synthesis of Polysiloxane and Polysilsesquioxane Resin II

[0083]

TABLE 2Monomers for Polysiloxane and Polysilsesquioxane Resin II:Methyl trimethoxy silane (Gelest, Morrisville, PA)67.8 gramsTetraethoxy silane (Gelest, Morrisville, PA)26.6 grams2-(3,4-Epoxycyclohexyl)ethyl trimethoxy silane3.14 grams(Gelest, Morrisville, PA)

[0084]Monomers in Table 2, together with 80 grams of propylene glycol methyl ether acetate (from Aldrich, Milwaukee, Wis.), were mixed in a 500-mL three-neck round-bottom flask. Attached to the flak were distillation condenser, thermometer, and nitrogen inlet. Nitrogen flow was set at 200 milliliters per minute. With stirring, temperature of the mixture in the flask was raised to 95° C. in oil bath. Then, 50 grams of 3-normal acetic acid were slowly added to the flask. Condensation reactions began. Volatile byproducts were distilled out of the flask and collected. Distillation completed in four hours. Heating stopped immediately after distillation is finished. Totally

example 3

Negative-Tone Photo-Imageable Hardmask Composition I

[0085]

TABLE 3Ingredients of Negative-tone Photo-imageable Hardmask Composition IResin I (from Example 1)38 gDiphenylsilanediol (Gelest, Morrisville, PA)0.2 gTriphenylsulfonium tris(trifluoromethyl)methide0.04 g(Ciba,Basel, Switzerland)Benzyltriethylammonium chloride0.01 g(Aldrich, Milwaukee, WI)Propylene glycol methyl ether acetate100 g

[0086]Composition I was made by mixing the ingredients in Table 3. When all the solids dissolved, the composition was filtered through a membrane with 0.02-micrometer pores. In the composition, film-modifier, that is diphenylsilanediol, is 5% of the resin by weight. Molar ratio of photoacid generator, that is triphenylsulfonium tris(trifluoromethyl)methide, to quencher, that is benzyltriethylammonium chloride, is 4 to 3. Photoacid generator load is 0.029% of total composition weight.

Lithographic Conditions for Composition I:Wafer spin speed for coating1500-3000 revolutions per minute for filmthickness o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap