OLED display substrate and manufacture method thereof

a technology of oled and display substrate, which is applied in the direction of basic electric elements, electrical apparatus, and semiconductor devices, can solve the problems of inability to light oled, and achieve the effect of simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]For better explaining the technical solution and the effect of the present invention, the present invention will be further described in detail with the accompanying drawings and the specific embodiments.

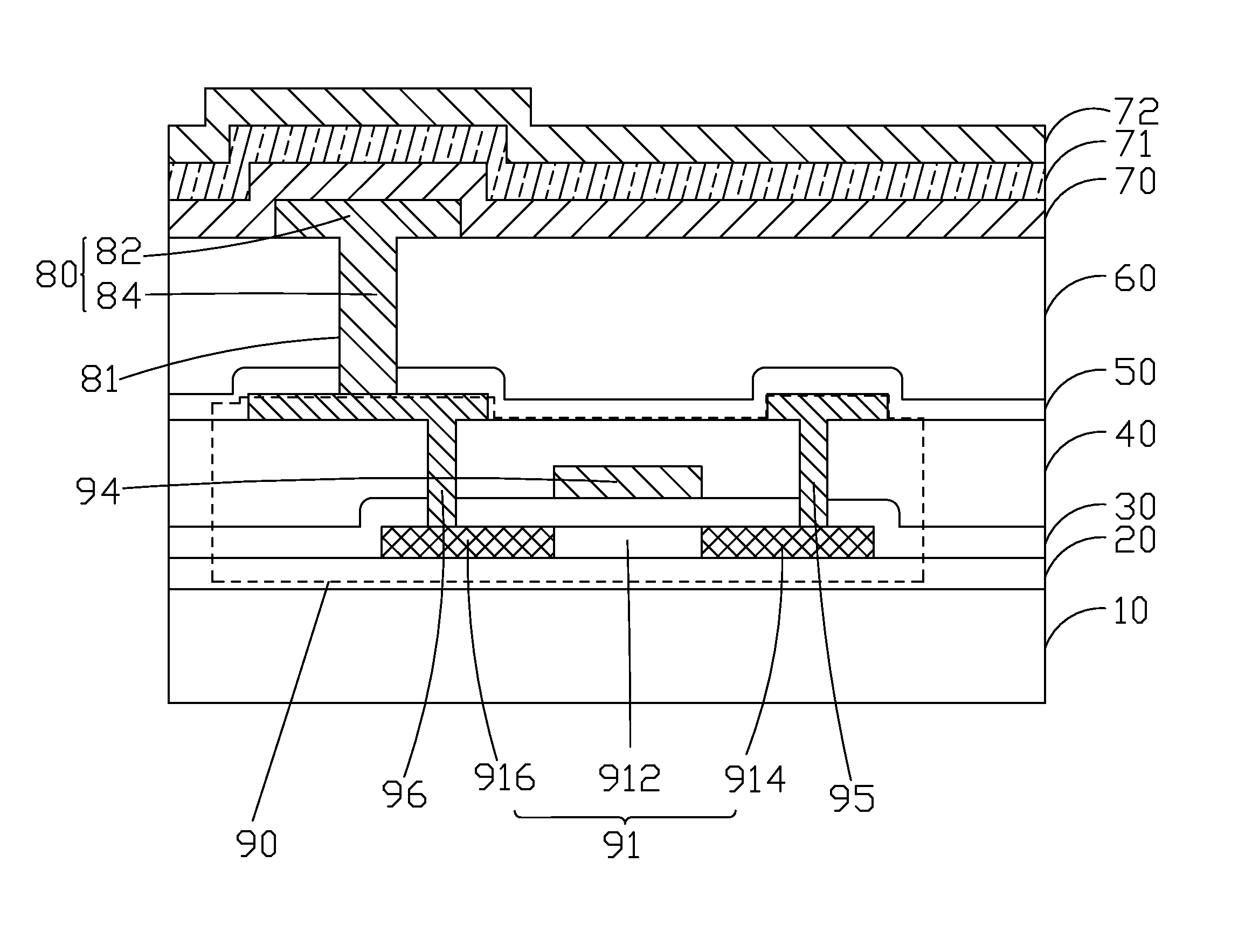

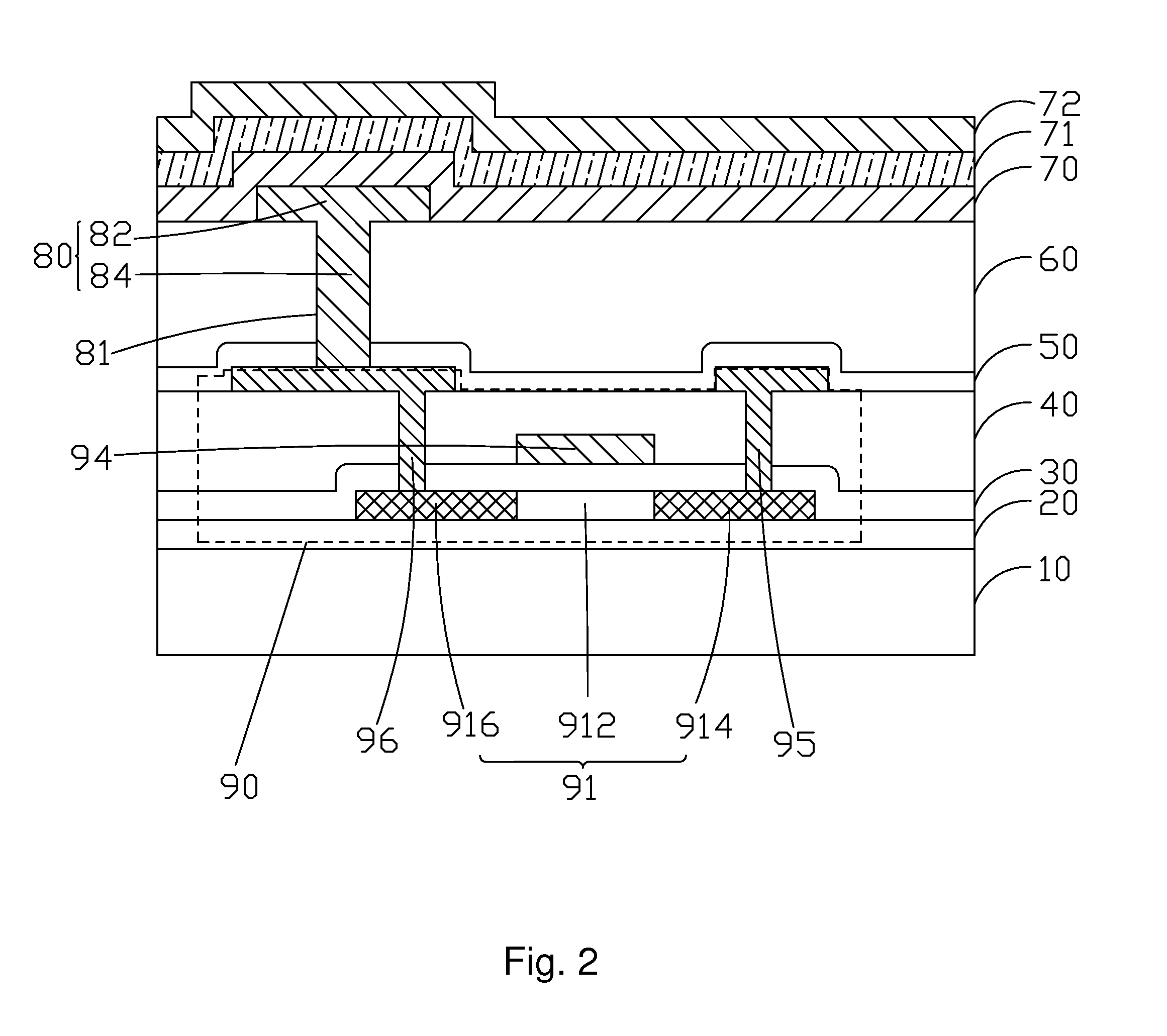

[0042]Please refer to FIG. 2. The present invention first provides an OLED display substrate, comprising:

[0043]a substrate 10, and the substrate 10 is a transparent substrate, and preferably, the substrate 10 is a glass substrate;

[0044]a TFT 90 located on the substrate 10; specifically, the TFT 90 comprises: a buffer layer 20 located on the substrate 10, a channel area 912 and a semiconductor layer 91 located in a source area 912 and a drain area 914 respectively at two sides of the channel area 912 on the buffer layer 20, a gate isolation layer 30 located on the semiconductor layer 91, a gate 94 located above the channel area 912 and on the gate isolation layer 30, an interlayer insulation layer 40 on the gate 94, a source 95 located in the source area 914 and penetrating the ga

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap