Reverse-conducting insulated-gate bipolar transistor structure and corresponding fabrication method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

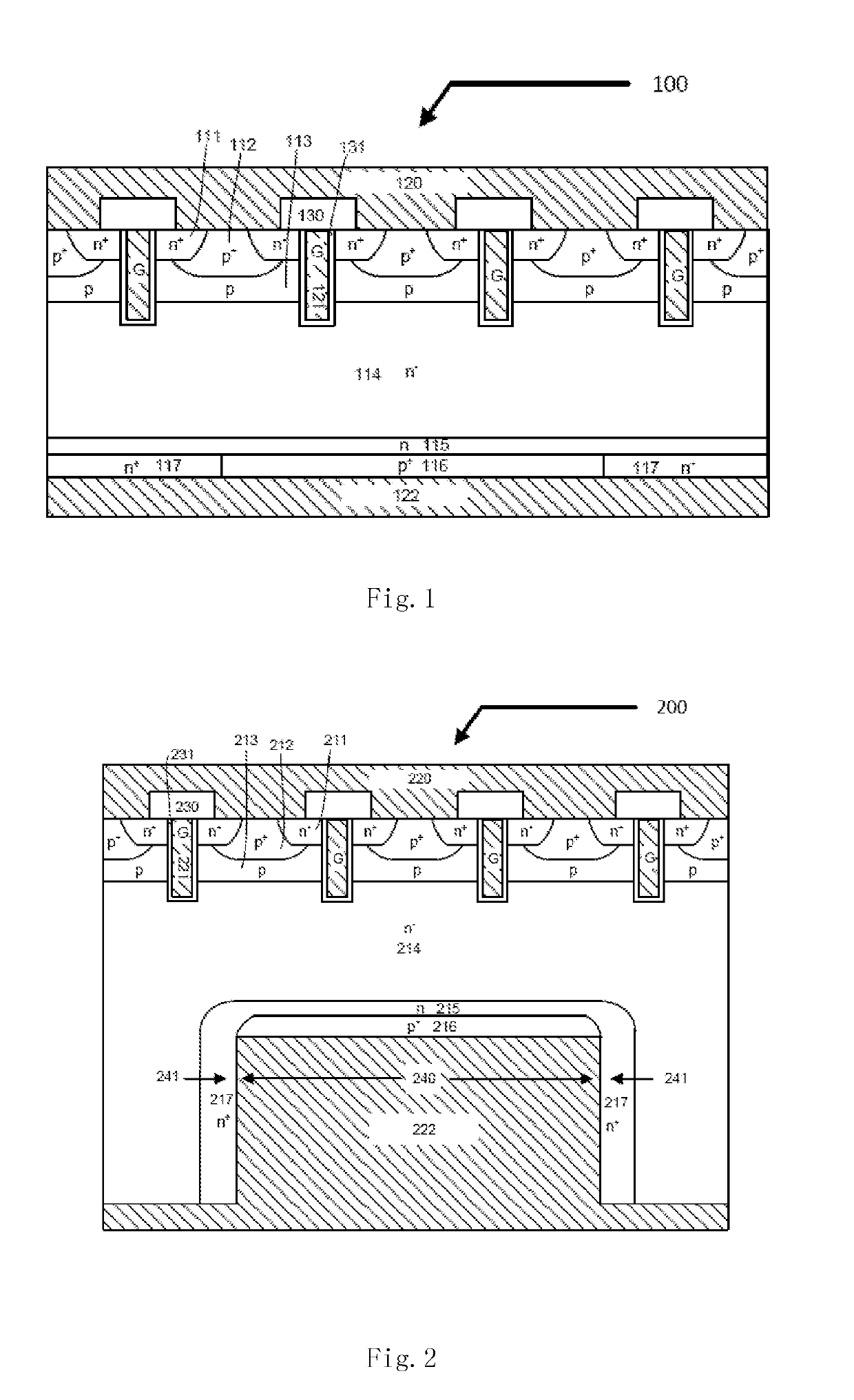

[0059]In the present invention, an n channel device is used to perform description. However, it should be understood that in the following descriptions that the present invention is similarly applicable to a p channel device. In the specification of the present invention, a heavily doped n− type region is marked as n+, and a heavily doped p-type region is marked as p+. Unless otherwise indicated, in silicon, a heavily doped region usually has a doping concentration between 1×1019 cm−3 and 1×1021 cm−3. In the specification of the present invention, a lightly doped n− type region is marked as n−, and a lightly doped p-type region is marked as p−. Unless otherwise indicated, in silicon, a lightly doped region usually has a doping concentration between 1×1013 cm−3 and 1×1017 cm−3.

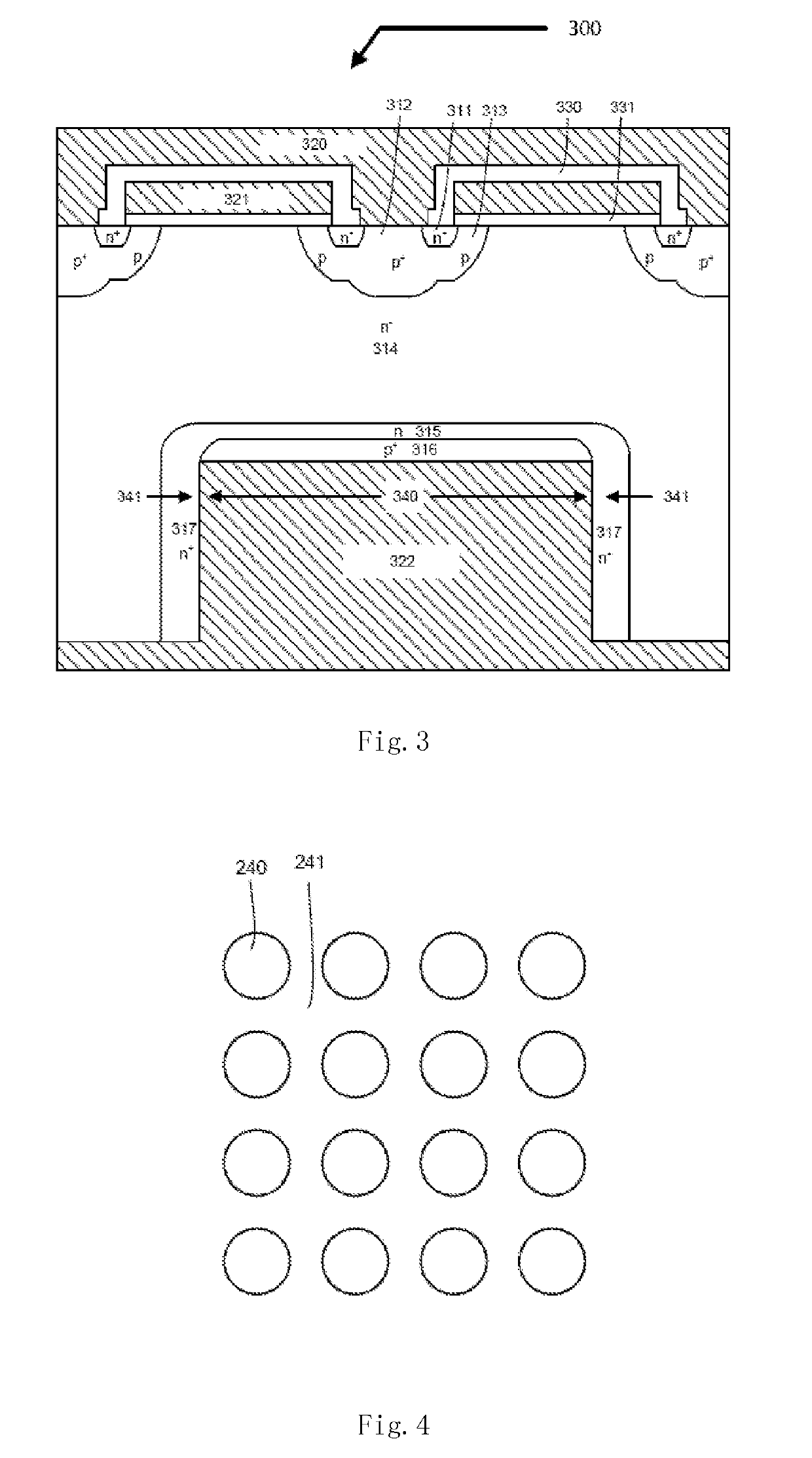

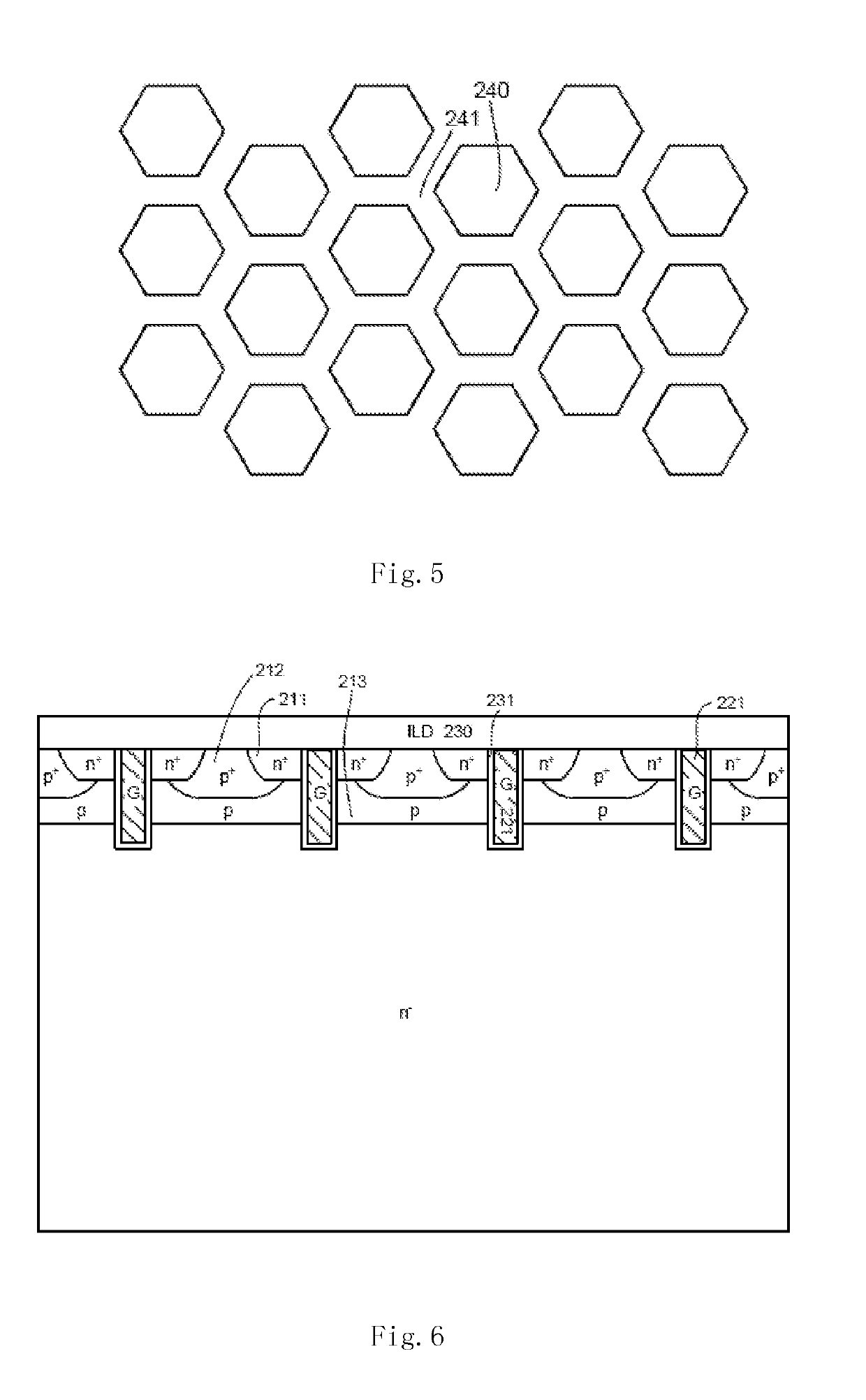

[0060]FIG. 2 is a cross-sectional view of the present invention implemented in a trench gate RC-IGBT device 200. The device 200 includes: an emitter electrode (220) at the front surface; a plurality of cell struct

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap