Polyvinyl alcohol composition, preparation method thereof, and polyvinyl alcohol medical catheter containing thereof

a polyvinyl alcohol and composition technology, applied in the field of macromolecular polymers, can solve the problems of difficult thermoplastic processing, limited application of polyvinyl alcohol, poor processability, etc., and achieve the effect of facilitating melt processing, reducing the melting point of polyethylene alcohol composition, and enhancing the processability of polyvinyl alcohol composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

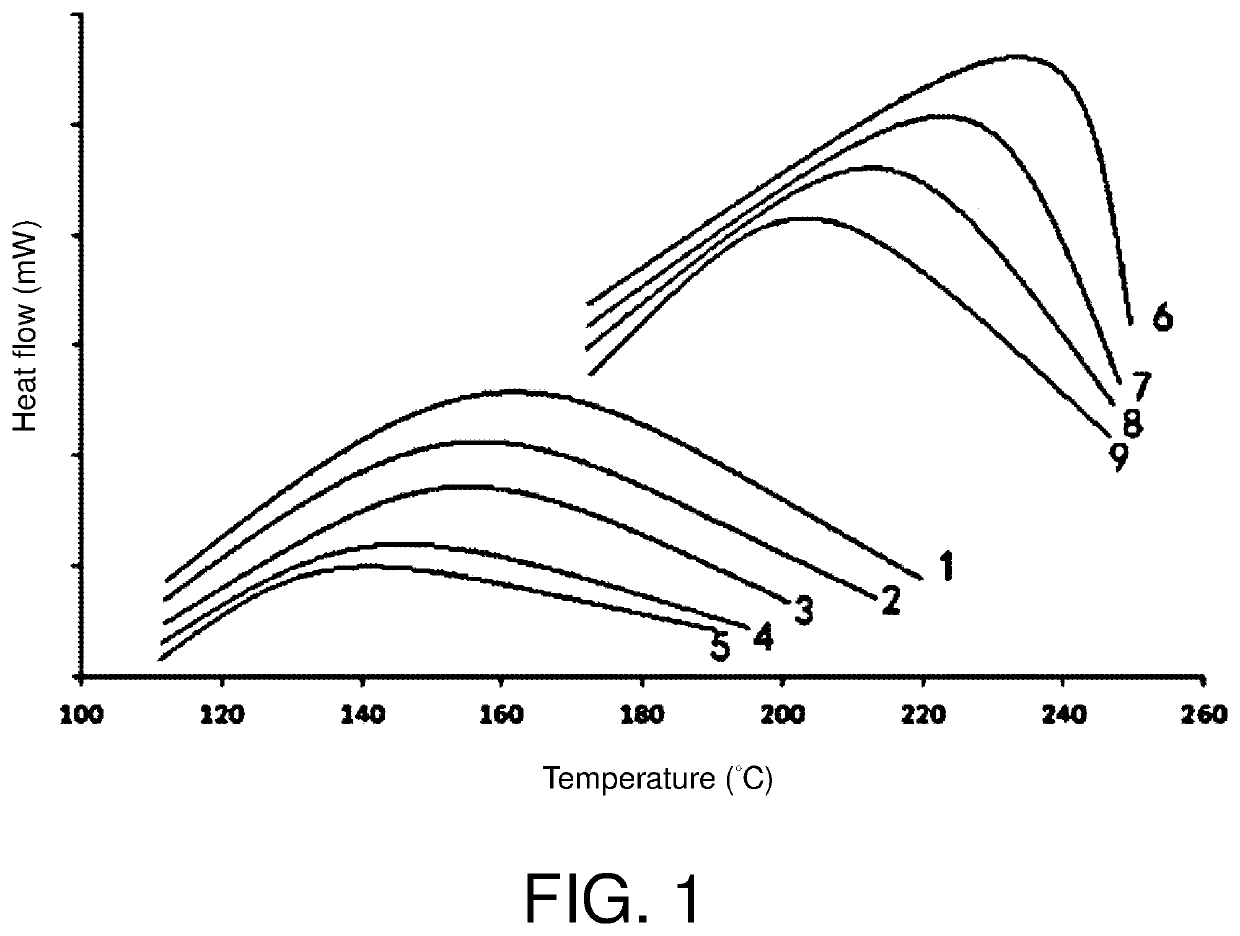

Image

Examples

example 1

[0037]A polyvinyl alcohol composition having the components of the raw materials shown in table 1 was prepared, in which the acid is aliphatic carboxylic acid, the polymerization degree of the polyvinyl alcohol is 7,000, and the alcoholysis degree is 99%.

[0038]The polyvinyl alcohol composition was prepared as follows: step 1: polyvinyl alcohol, glycerol, calcium chloride, and the acid were mixed, extruded with an extruder, and pelletized with a pelletizer to obtain an acidic polyvinyl alcohol material, in which the extruder is a twin screw extruder, the length diameter ratio is 40-60:1, and the temperature inside the extruder is 160-220° C.

[0039]Step 2: glutaraldehyde and the acidic polyvinyl alcohol material obtained in step 1 were mixed and extruded with an extruder to obtain an intermediate material of the polyvinyl alcohol composition, in which the temperature inside the extruder is 160-220° C.

[0040]Step 3: the intermediate material of the polyvinyl alcohol composition from step 2

example 2

[0042]A polyvinyl alcohol composition having the components of the raw materials shown in table 1 was prepared, in which the acid is pyrophosphoric acid, the polymerization degree of the polyvinyl alcohol is 6,000, and the alcoholysis degree is 80%.

[0043]The polyvinyl alcohol composition was prepared as follows: step 1: the polyvinyl alcohol, urea, glycerol, calcium chloride, and the acid were mixed, extruded with an extruder, and pelletized with a pelletizer to obtain an acidic polyvinyl alcohol material, in which the extruder is a twin screw extruder, the length diameter ratio is 40-60:1, and the temperature inside the extruder is 150-180° C.

[0044]Step 2: glutaraldehyde and the acidic polyvinyl alcohol material obtained in step 1 were mixed and extruded with an extruder to obtain an intermediate material of the polyvinyl alcohol composition, in which the temperature inside the extruder is 150-180° C.

[0045]Step 3: the intermediate material of the polyvinyl alcohol composition from ste

example 3

[0047]A polyvinyl alcohol composition having components of the raw materials of the polyvinyl alcohol composition shown in table 1 was prepared, in which the acid is disulfuric acid, the polymerization degree of the polyvinyl alcohol is 4,000, and the alcoholysis degree is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap