Power supply device and electric vehicle provided with power supply device

a technology of power supply device and power supply device, which is applied in the direction of vehicle sub-unit features, cell components, batteries, etc., to achieve the effect of preventing lateral displacement of battery cells, preventing rotation of bent pieces, and preventing displacement of bind bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

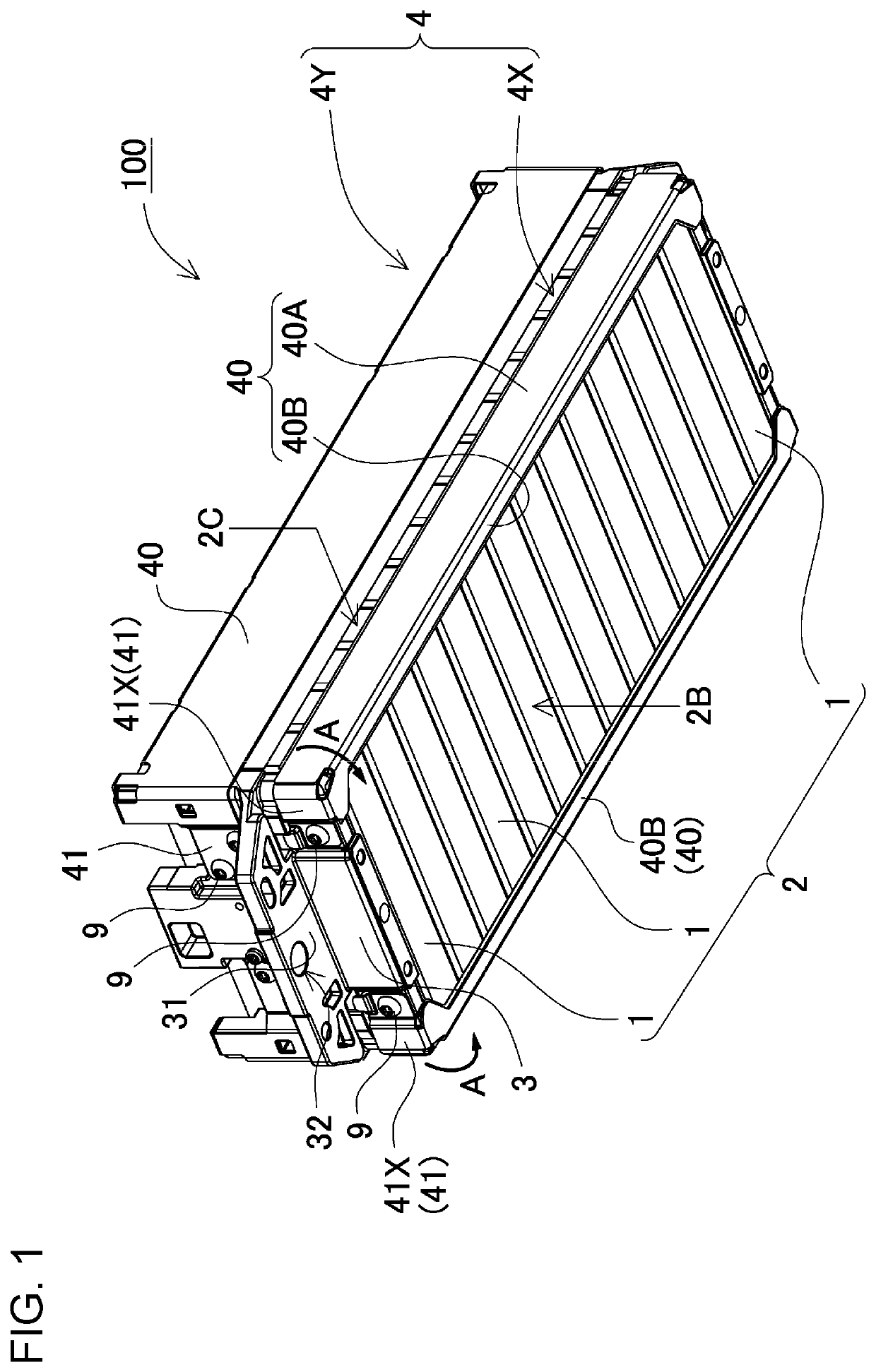

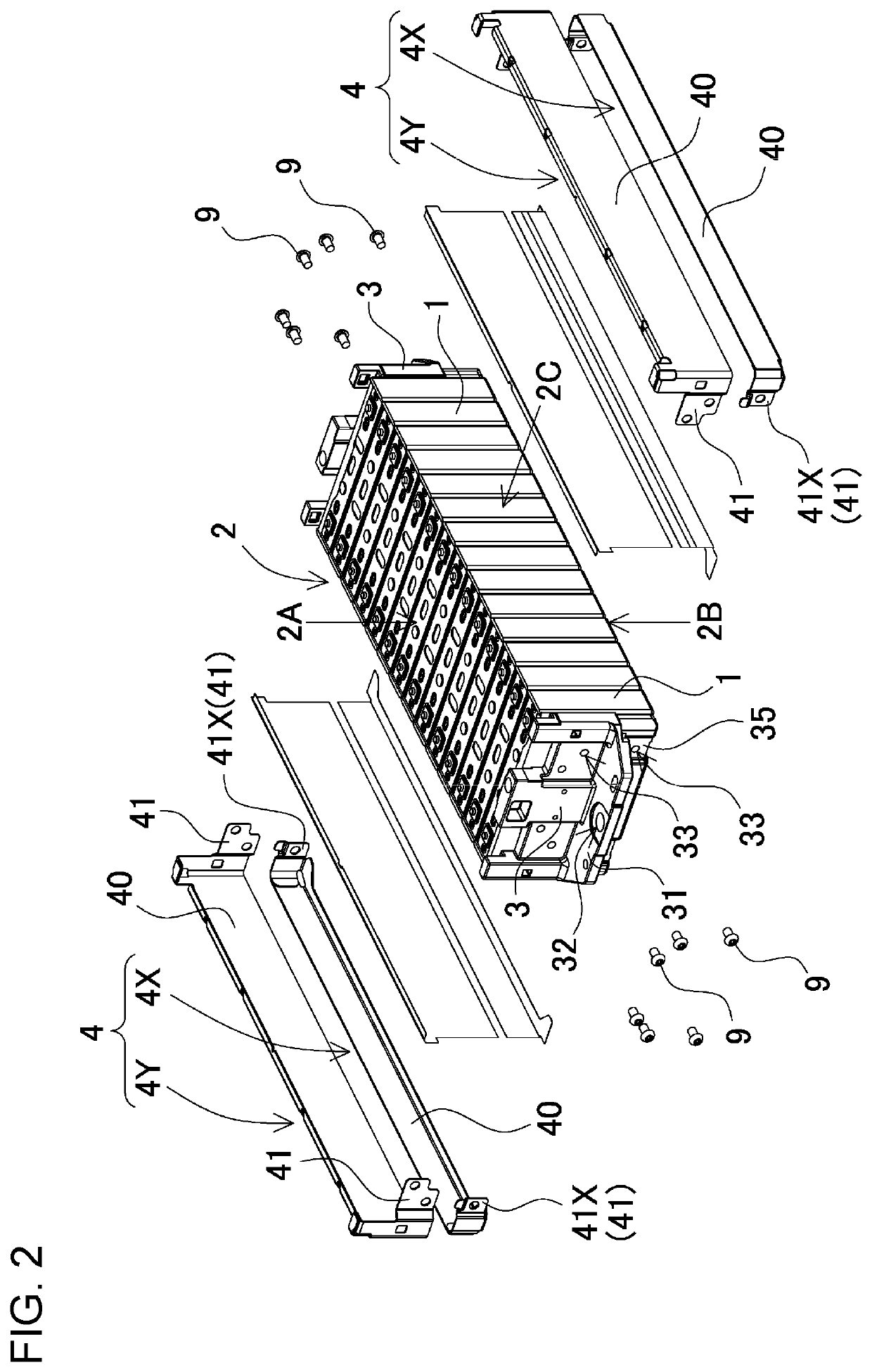

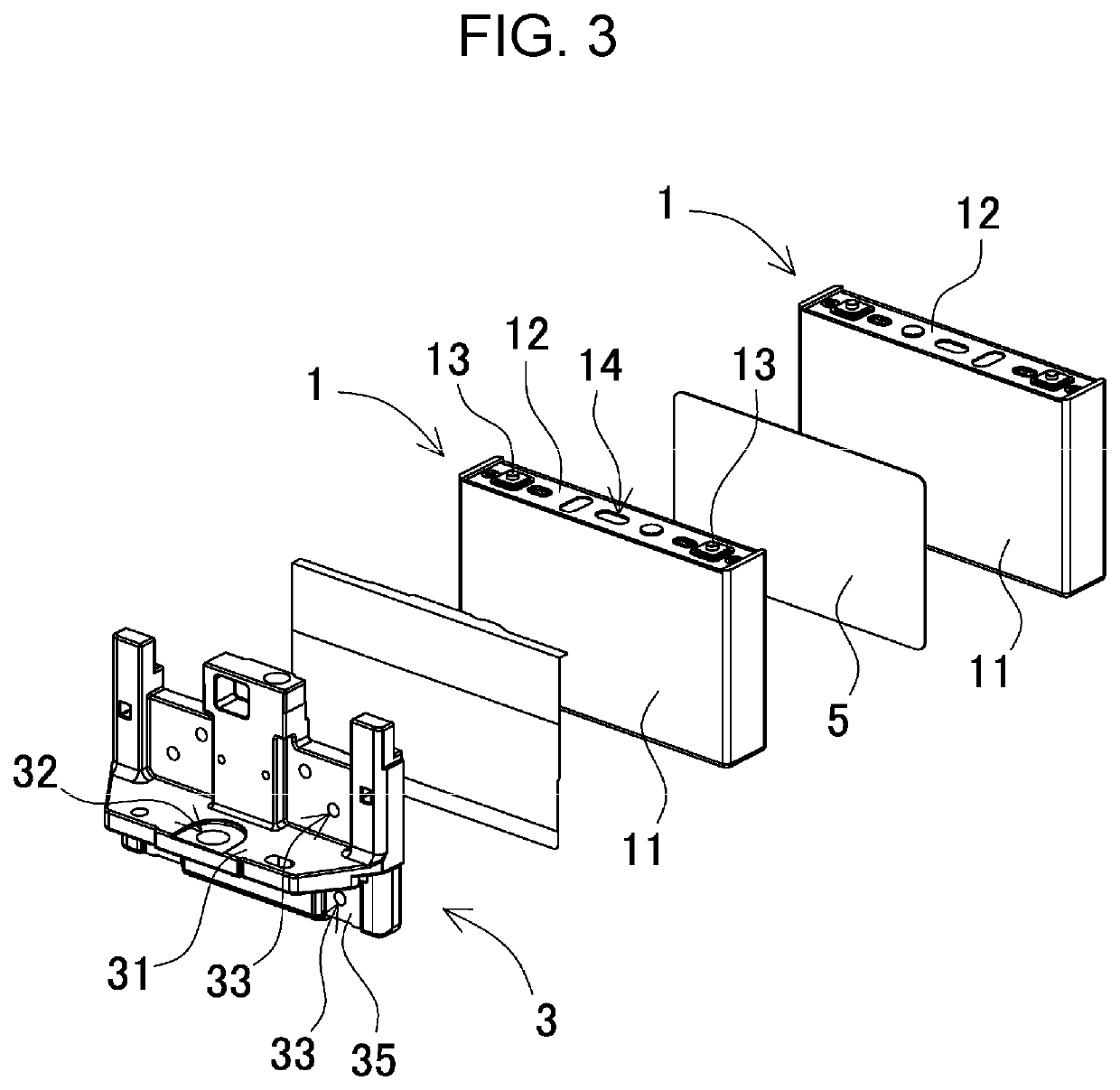

[0016]First, one point of interest of the present invention will be described. A power supply device in which a plurality of battery cells are stacked to form a battery stack and a pair of end plates disposed on both end surfaces of the battery stack are coupled by a bind bar can be made wider in a vertical width to increase a tensile strength. However, since the power supply device is required to have an optimal structure for an application, the bind bar disposed on one surface of the battery stack cannot always be formed of one metal plate, and the bind bar may be required to be vertically divided. For example, in a structure in which a fixing flange for fixing the power supply device to an external device projects in a middle in a vertical direction of the end plates, or in a structure in which there is a projecting portion in a central part of a side surface of the battery stack, the bind bar is required to be vertically divided and to be fixed the end plates. In the power supply d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap