Method of removing sulfur dioxide from flue gases and treatment of oxidized effluent therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

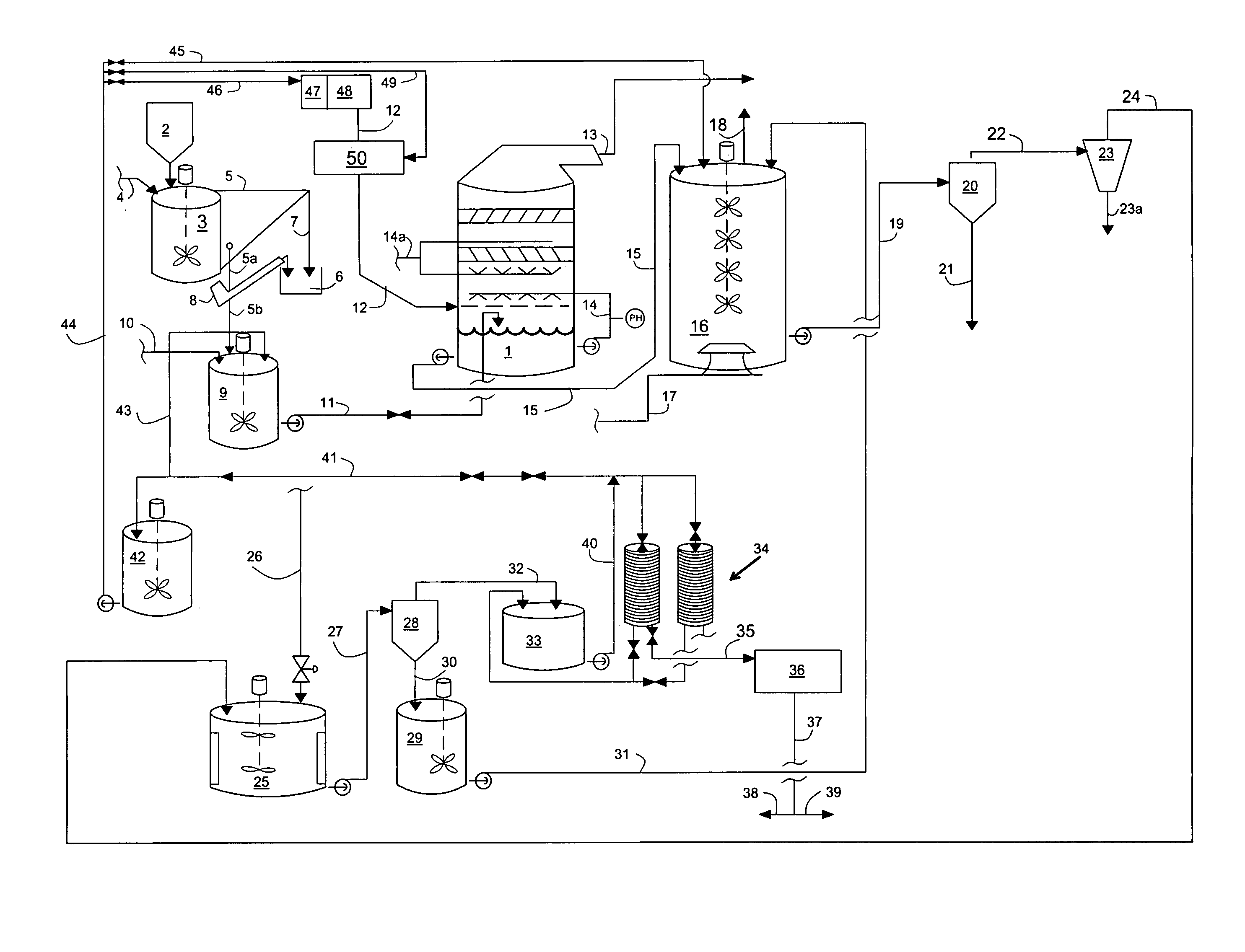

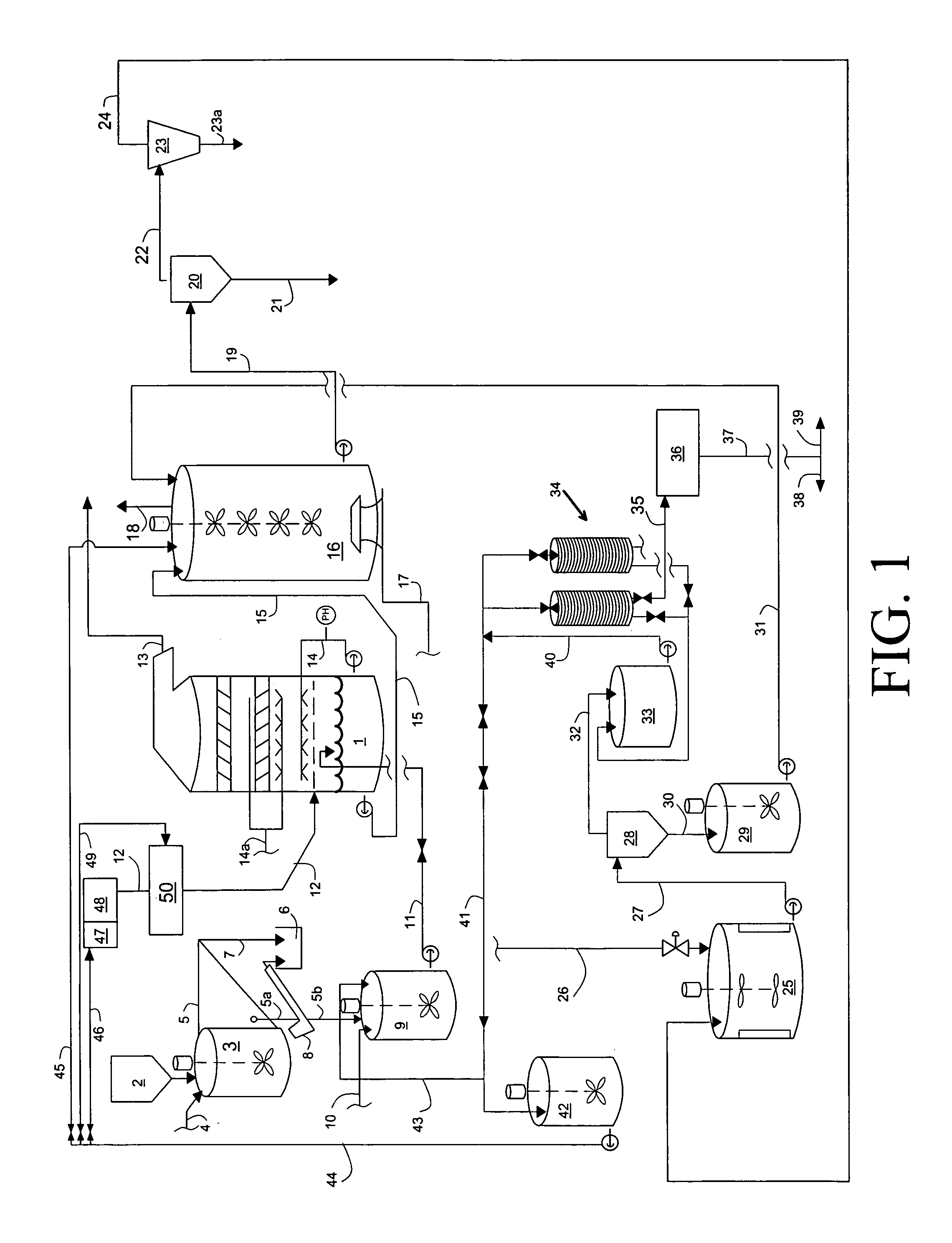

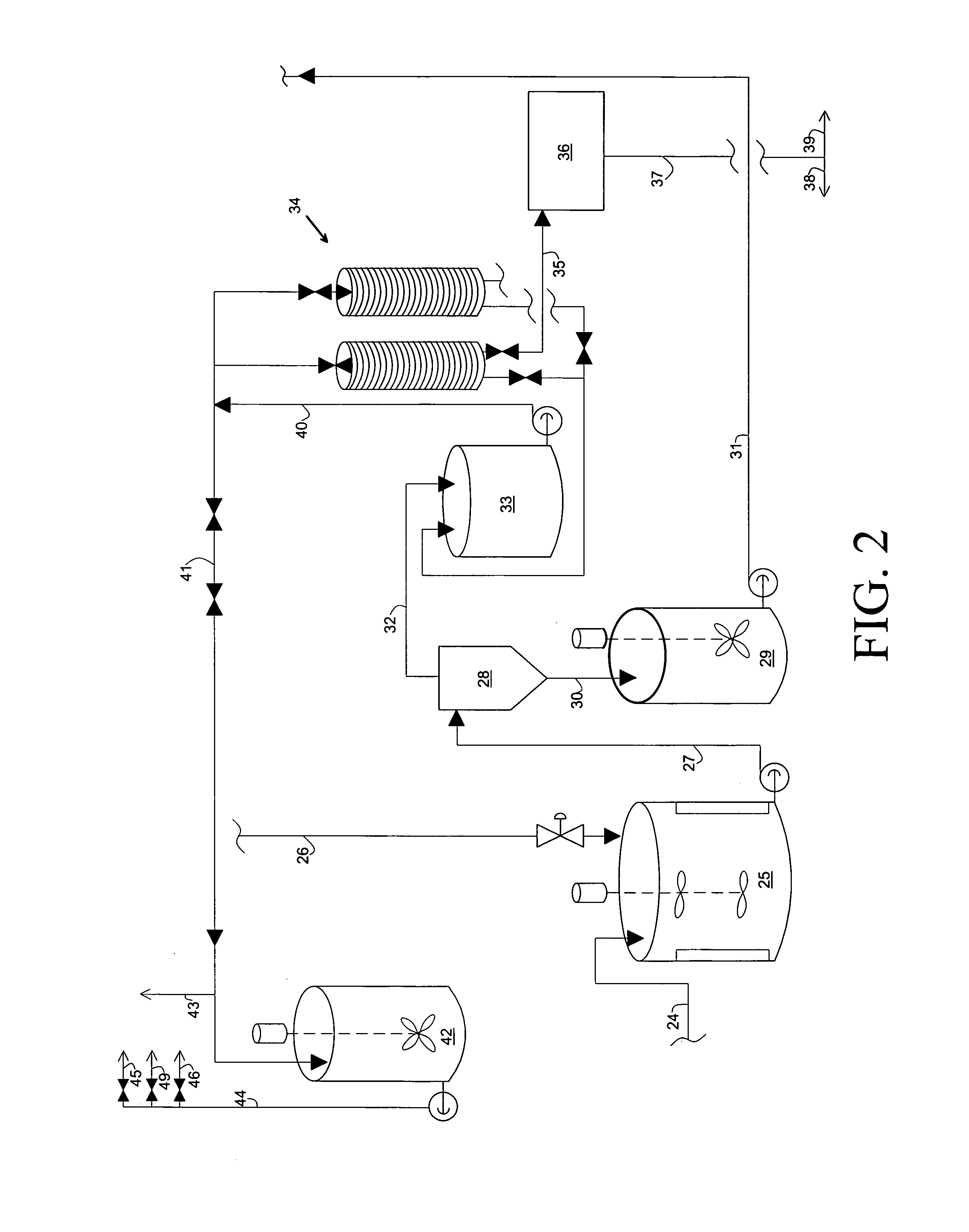

[0018]The present invention provides a method of removing sulfur dioxide from a flue gas stream of a power plant boiler using a wet scrubber, and a method for treating a bleed stream from a magnesium-containing portion of an oxidized effluent from an oxidizer, resulting from a magnesium-enhanced calcium slurry sulfur dioxide removal process, the oxidized effluent containing magnesium sulfate, gypsum and amorphous inert material.

[0019]Referring now to FIG. 1, as shown therein, an aqueous scrubbing slurry is contacted with a sulfur dioxide-containing gas in a wet scrubbing unit 1, so as to remove sulfur dioxide therefrom. The aqueous scrubbing slurry contains magnesium scrubbing components, and an especially useful slurry contains magnesium-enhanced lime. Lime or limestone may be used, although the following description will describe the use of lime as the calcium scrubbing component. Such a general process is described in U.S. Pat. No. 5,645,807 to Tseng et al., and U.S. Pat. No. 6,572,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap