Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Anthracite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anthracite, often referred to as hard coal, is a hard, compact variety of coal that has a submetallic luster. It has the highest carbon content, the fewest impurities, and the highest energy density of all types of coal and is the highest ranking of coals.

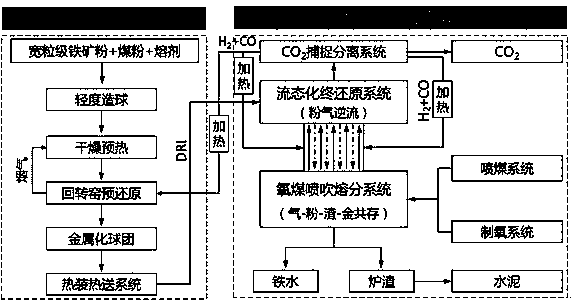

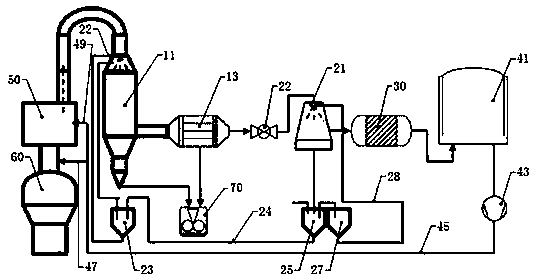

High density total oxygen short process high-efficiency cleaning iron-making process

InactiveCN108754056ASave the coking processSave grinding costRotary drum furnacesGas emission reductionCo2 removalSlag

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

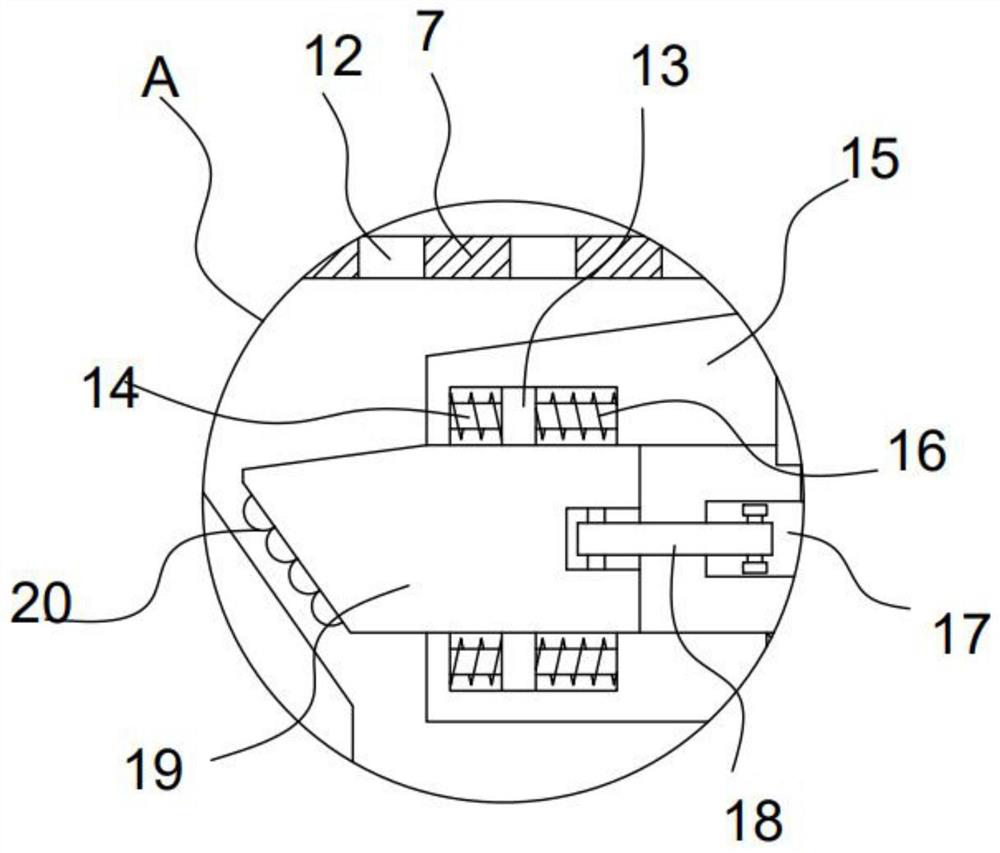

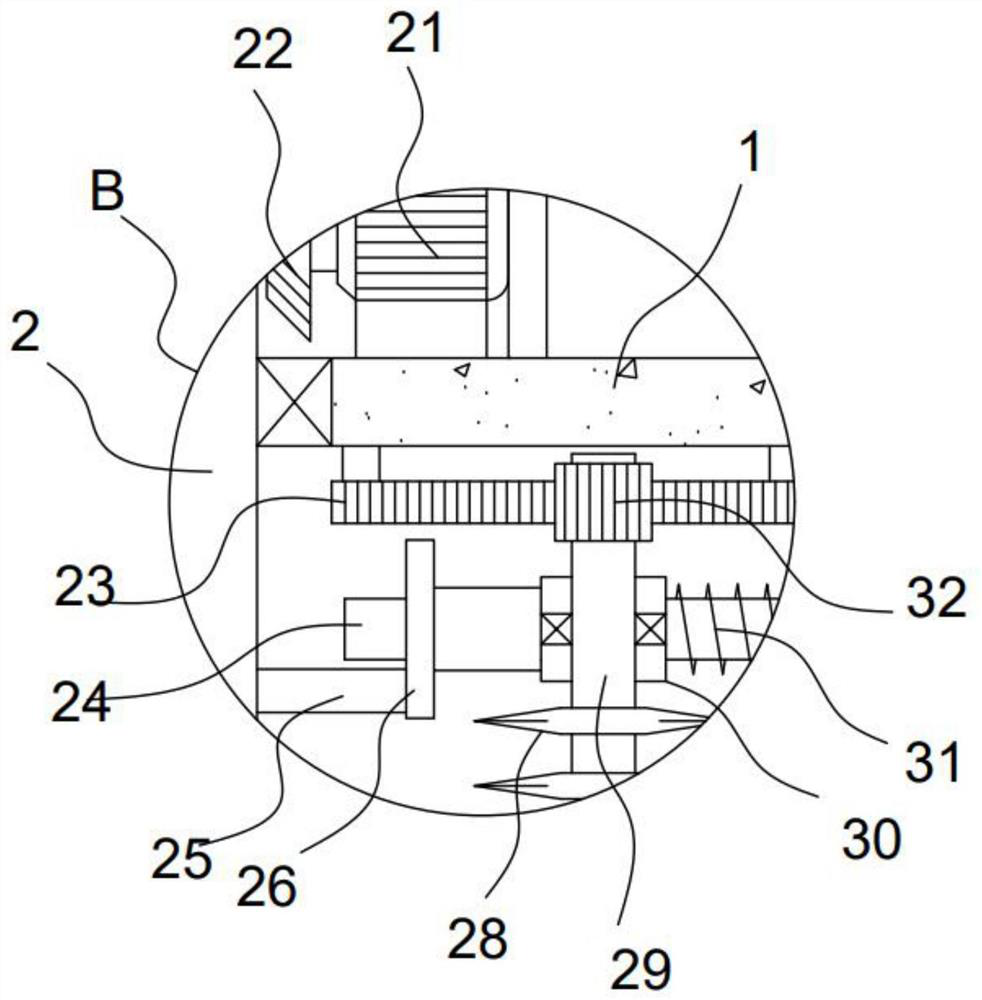

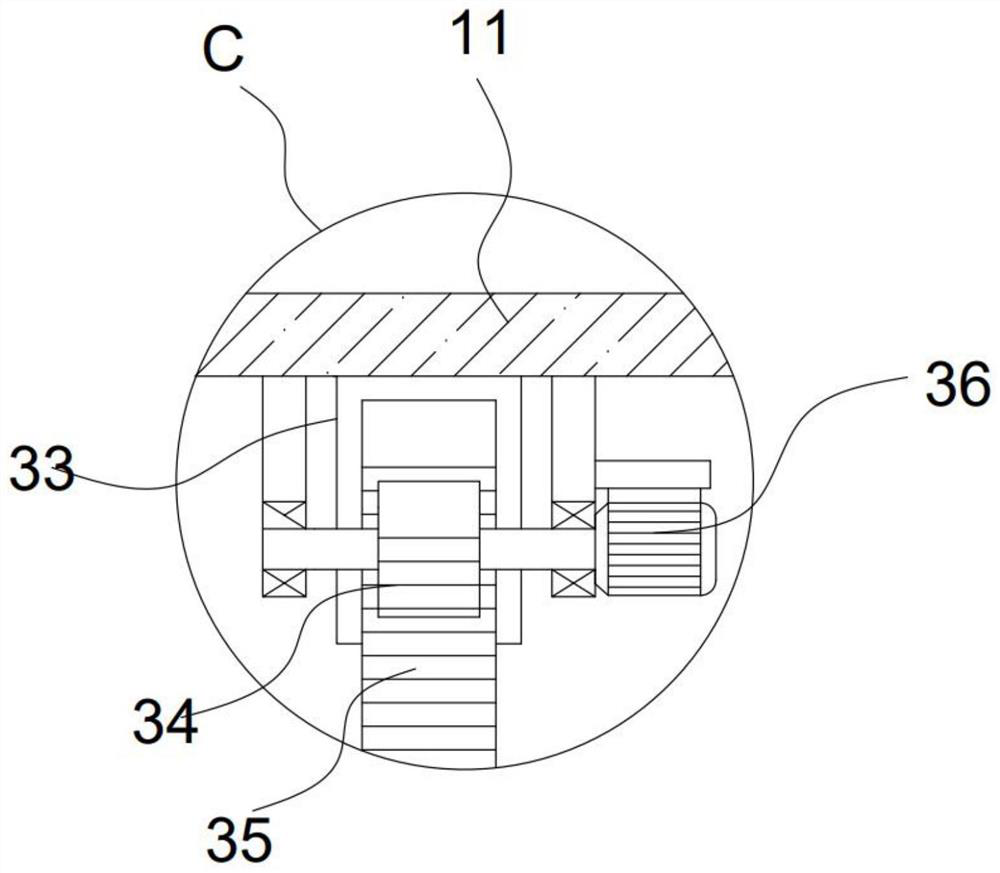

Raw material pretreatment device for hydrogen purification

InactiveCN113210089ARealize the rotary shredding effectImprove chopping effectGrain treatmentsReciprocating motionStructural engineering

Owner:WUHU MEDIUM HYDROGEN NEW ENERGY TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap