Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Coal gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal gasification is the process of producing syngas–a mixture consisting primarily of carbon monoxide (CO), hydrogen (H₂), carbon dioxide (CO₂), natural gas (CH₄) , and water vapour (H₂O)–from coal and water, air and/or oxygen.

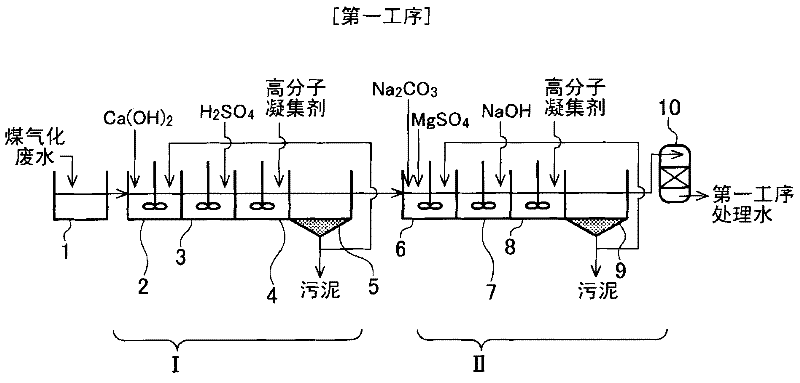

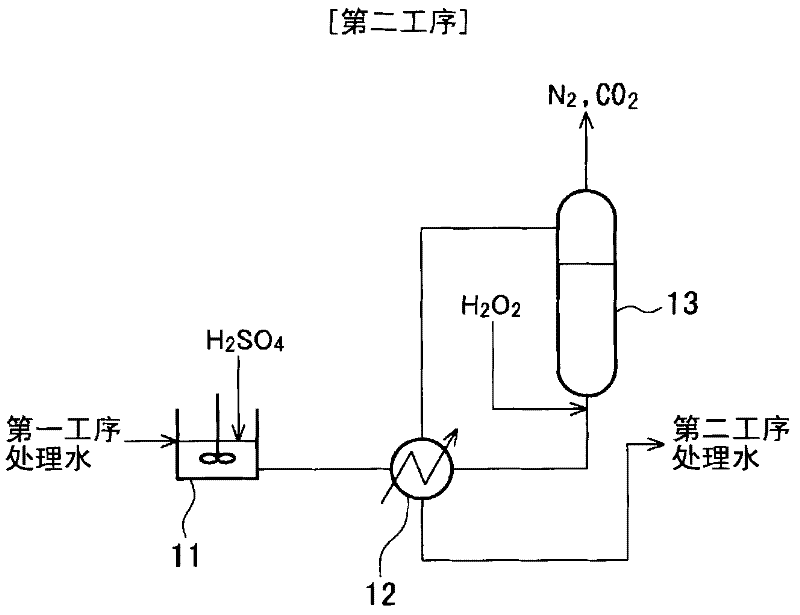

Method of treating coal gasification wastewater

InactiveCN102348648AImprove water qualitySludge treatment by oxidationWater contaminantsCoal gasification wastewaterReduction treatment

Owner:KURITA WATER INDUSTRIES LTD

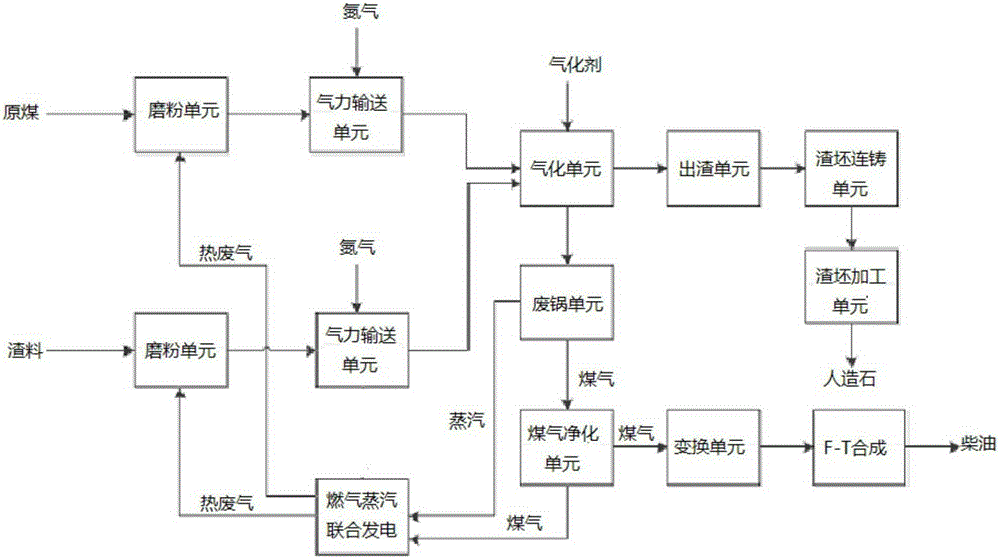

Artificial stone and preparation method thereof

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

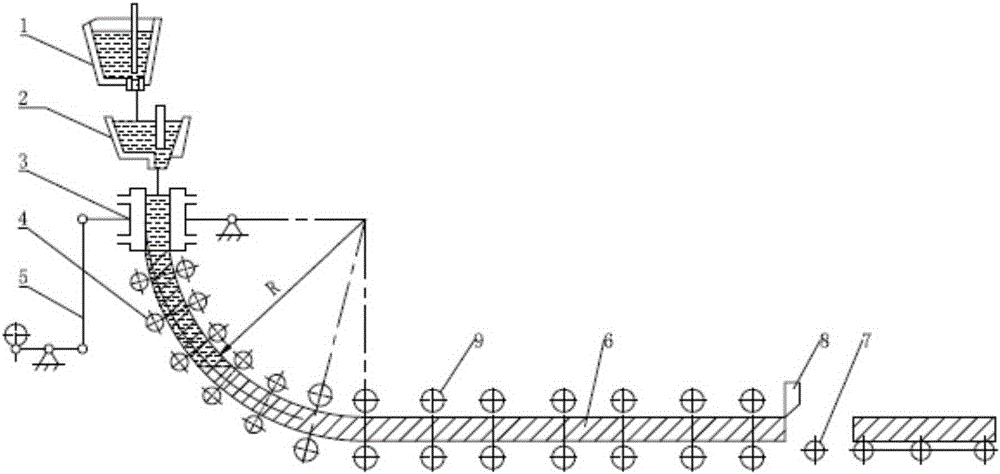

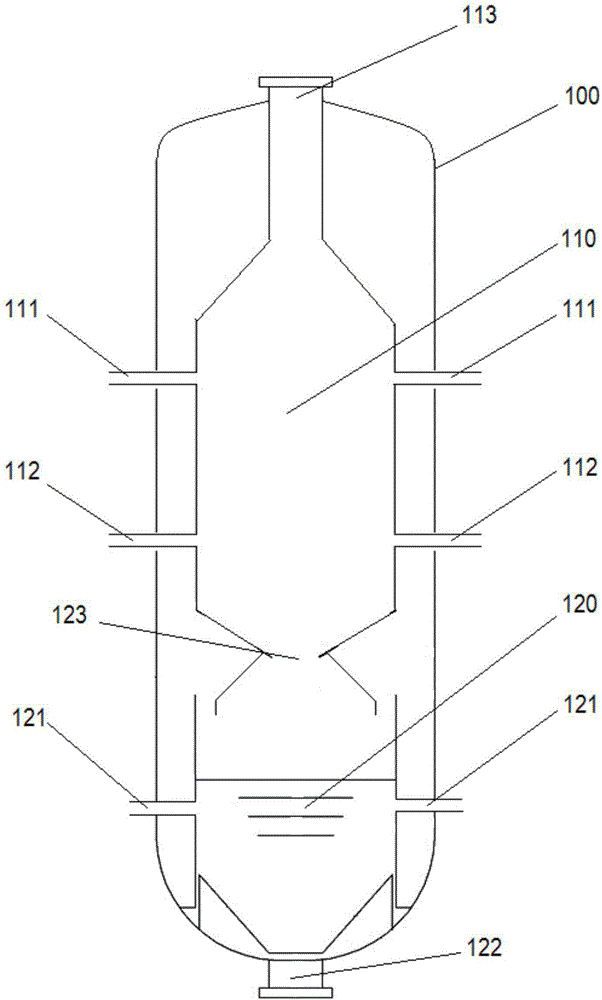

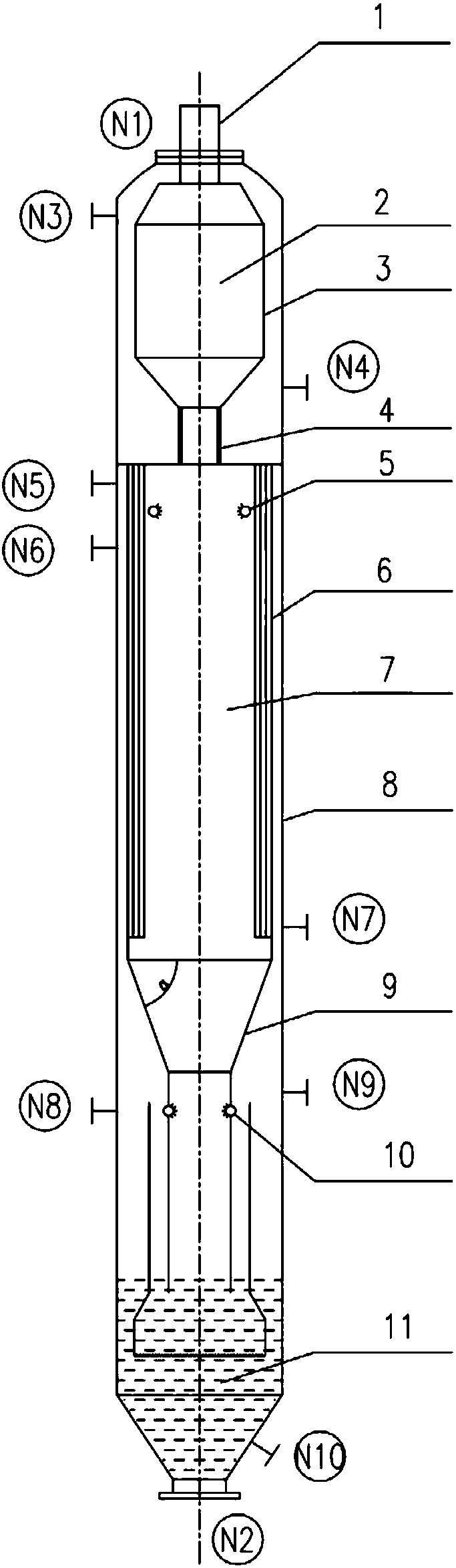

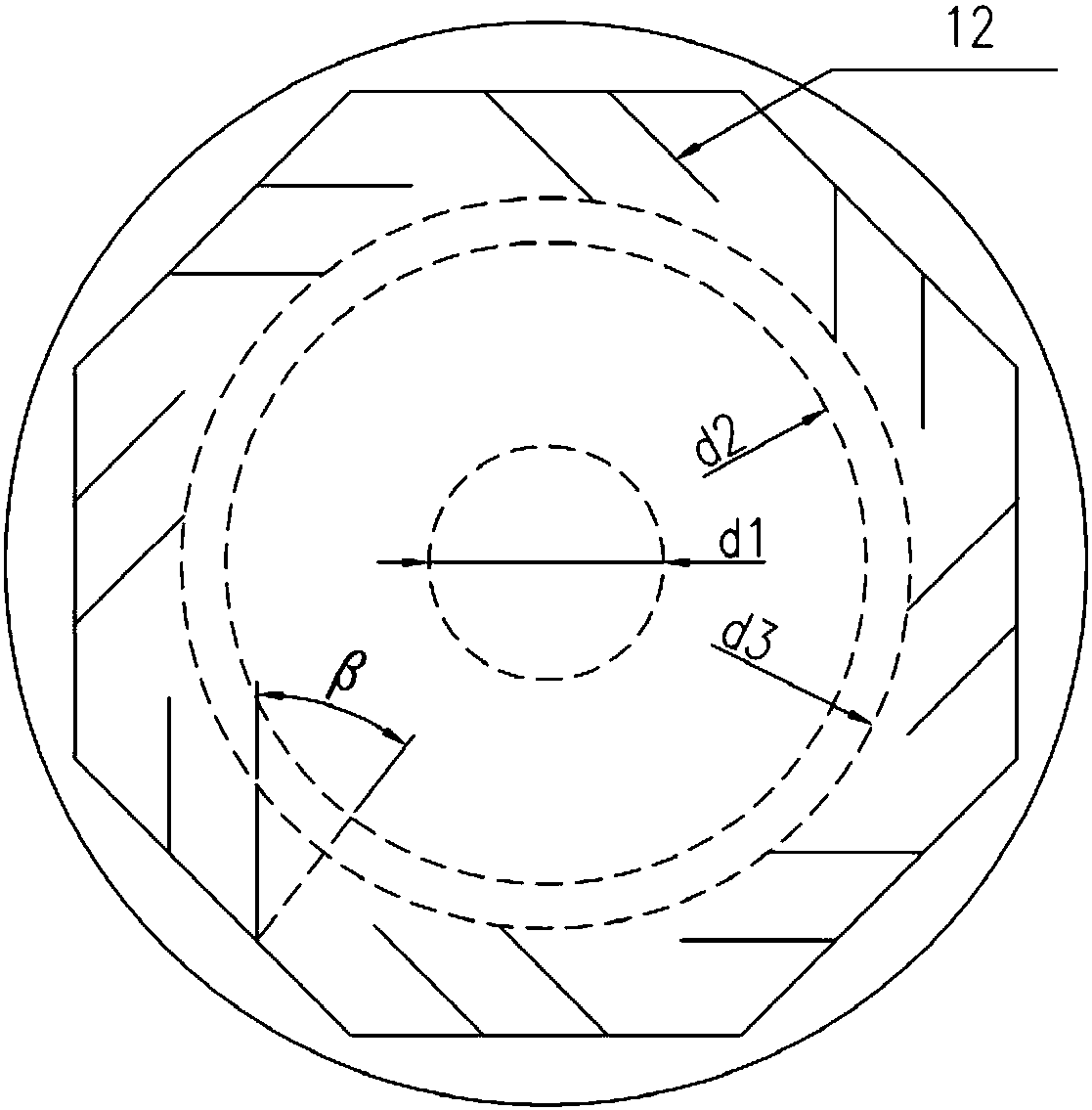

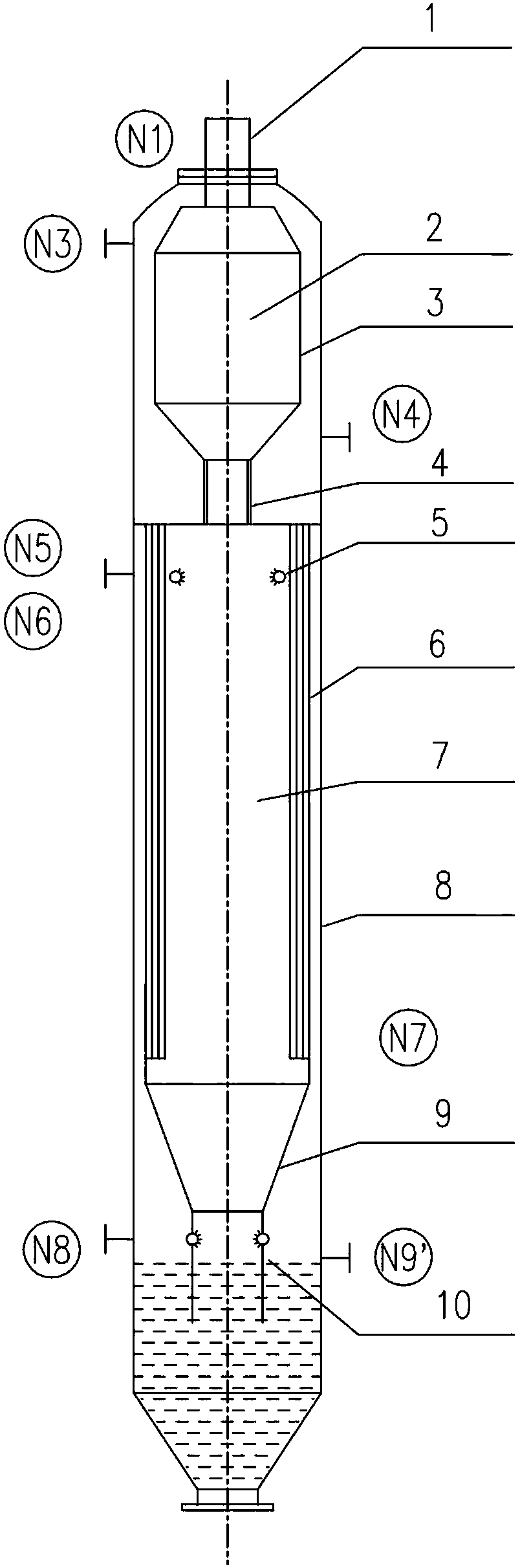

Gasification furnace with radiation heat exchange and gasification method

PendingCN110684562AReduce disturbanceGood followabilityGasification processes detailsGranular/pulverulent flues gasificationSyngasSlag

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Coal underground gasification monitoring device

InactiveCN114000861AAffect accuracyAchieve precisionSurveyConstructionsMechanical engineeringPetroleum engineering

The invention discloses a coal underground gasification monitoring device, and belongs to the technical field of coal gasification, the coal underground gasification monitoring device comprises a mounting rack, a position displacement monitoring component, a dust cleaning monitoring component and a gas gasification monitoring component, the position displacement monitoring component is located on the mounting rack, and the dust cleaning monitoring component is located at the telescopic end of the position displacement monitoring component; the dust cleaning monitoring component comprises a mounting cylinder, a gas swing assembly and a dust blocking assembly, the mounting cylinder is connected with the telescopic end of the dust cleaning monitoring component, the gas swing assembly is located at the bottom of the mounting cylinder, and the dust blocking assembly is located in the mounting cylinder and is in sliding fit with the mounting cylinder; and the gas gasification monitoring component is located in the position displacement monitoring component and communicates with the mounting cylinder. According to the invention, gas in supervision gas is filtered through the gas swing assembly and the dust blocking assembly, so that accurate supervision data can be obtained.

Owner:徐斌

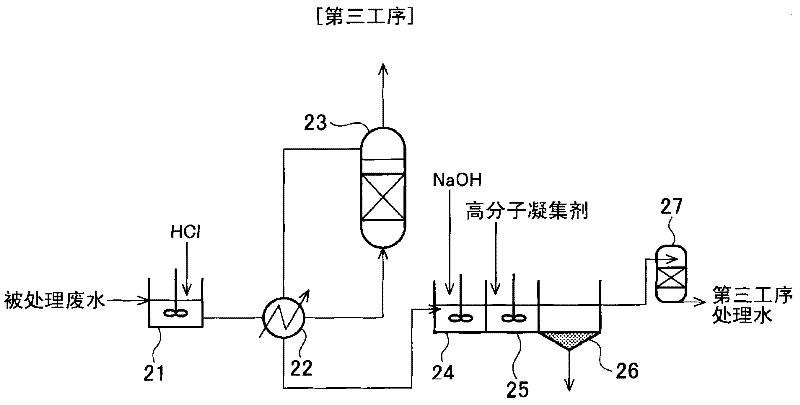

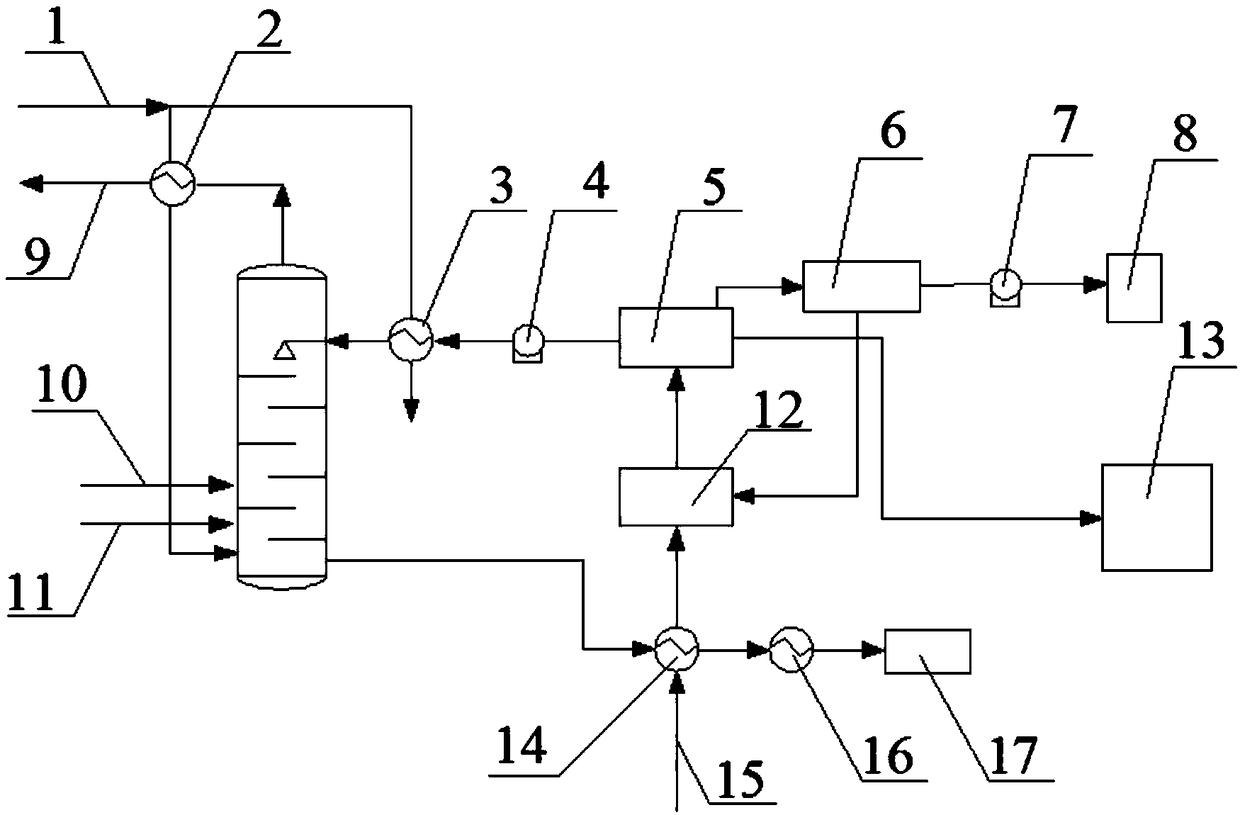

Gas liquor purification treatment system after coal gasification

PendingCN108911345AReduce contentReduce pollutionWater treatment parameter controlFatty/oily/floating substances removal devicesEngineeringImpurity

Owner:SHANXI HEIMAO JIAOHUA CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap