Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Control layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control Layer. Define and control who can do what in your organization, and maintain full audit trails of changes to critical data. The control layer is one of the three foundational layers that provide Projector’s core functionality.

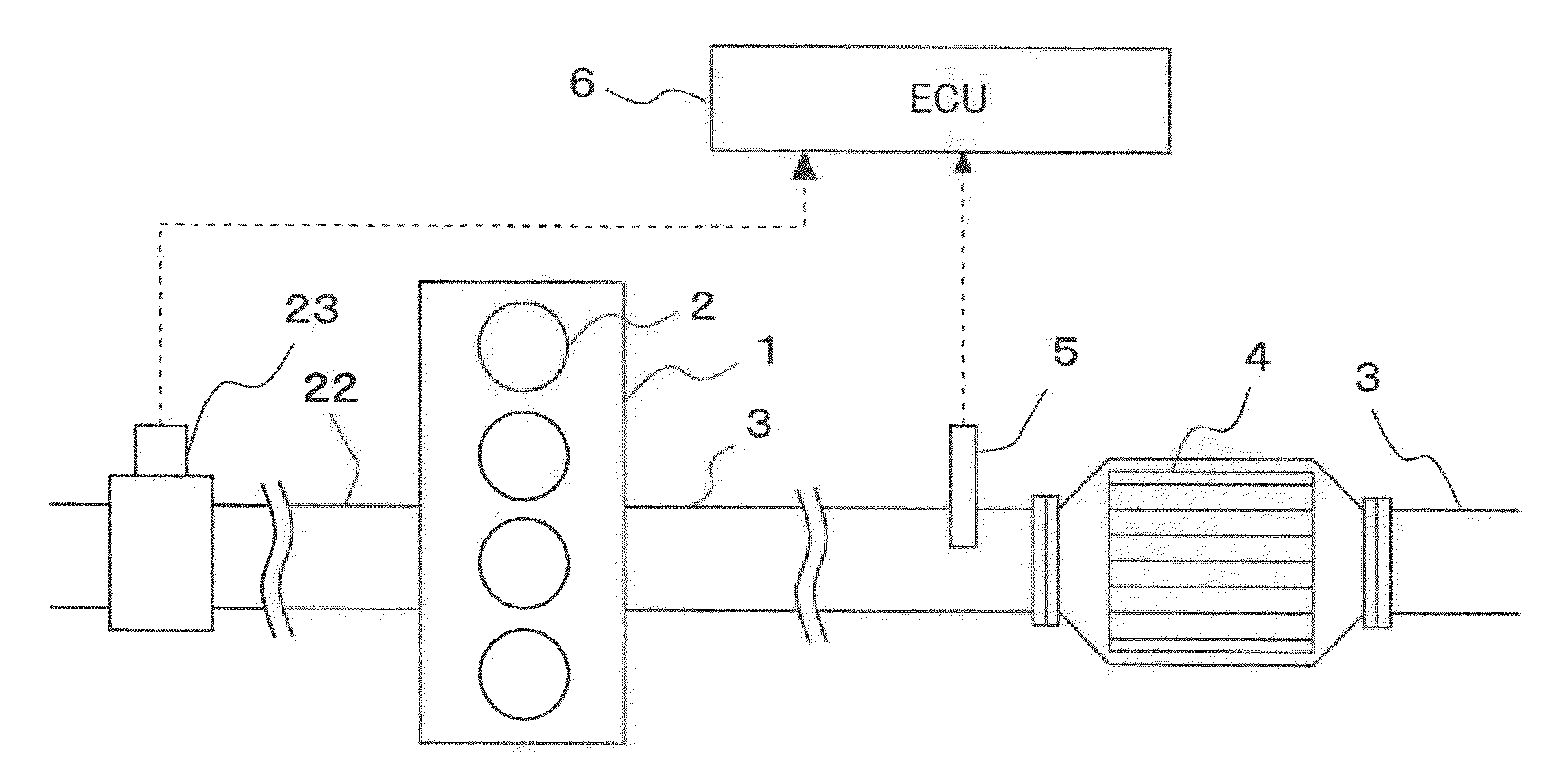

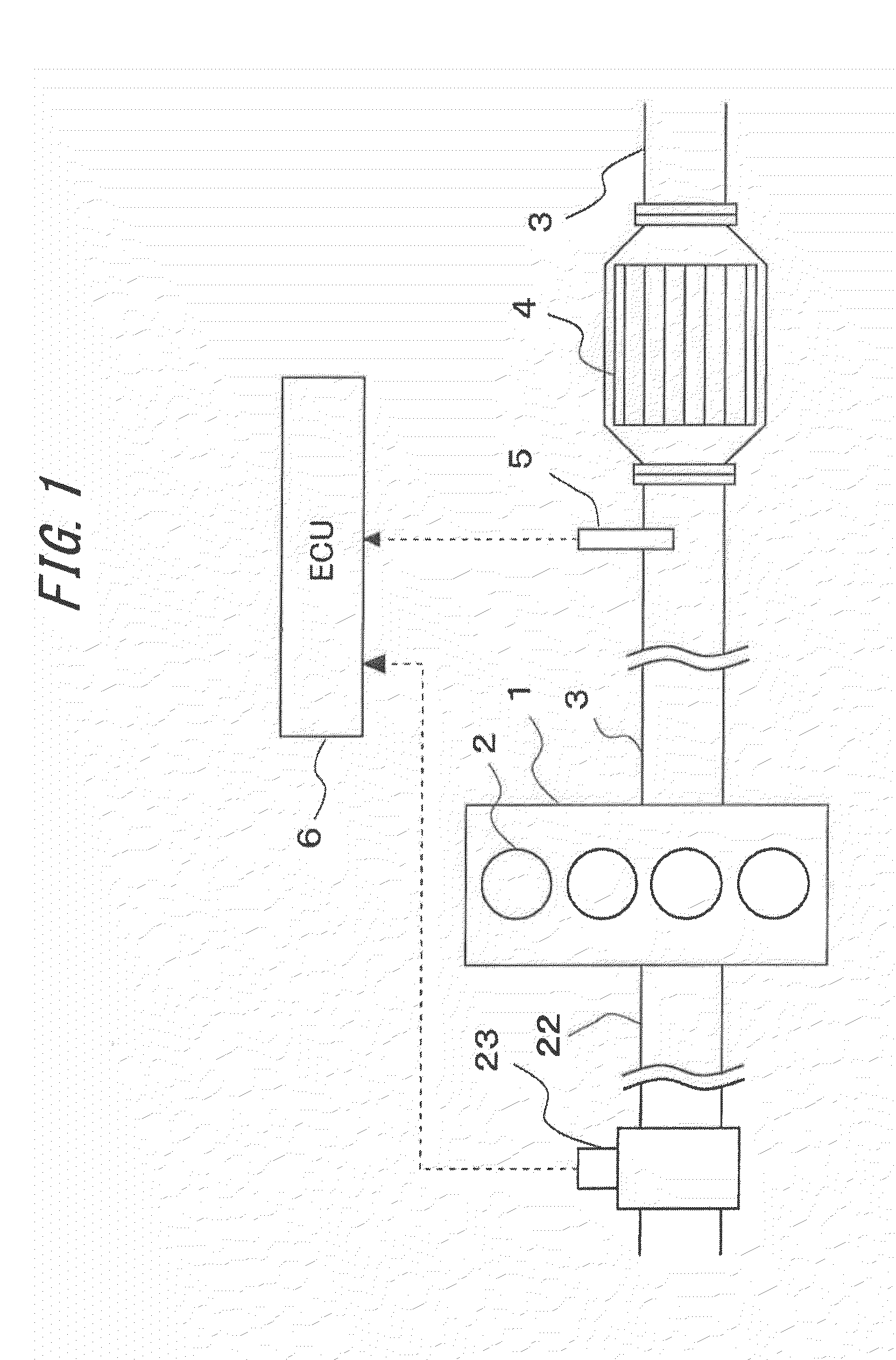

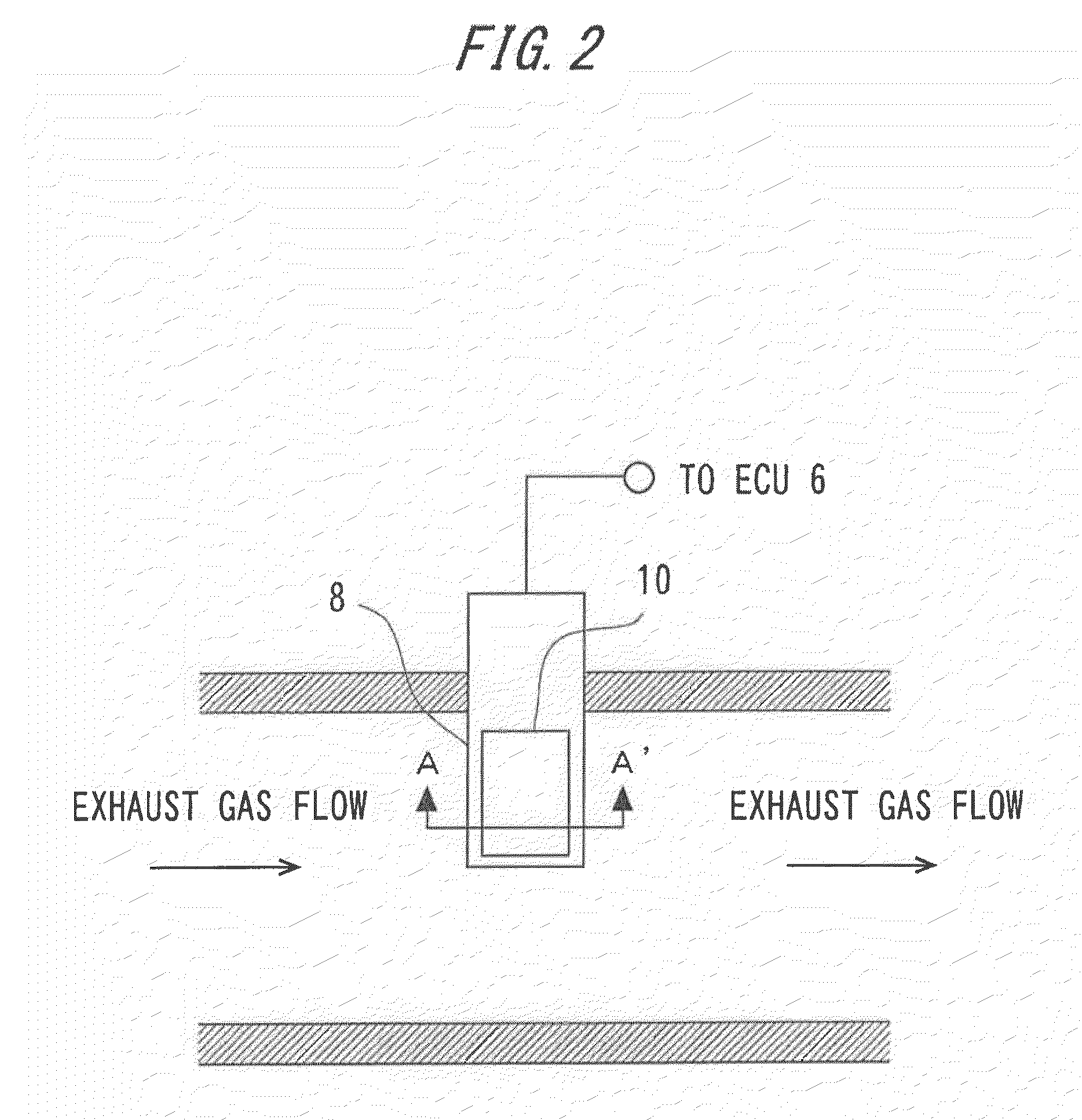

Air-fuel ratio sensor and control apparatus for internal combustion engine

InactiveUS20100300418A1Improve responsivenessElectrical controlExhaust apparatusControl layerAtmospheric air

Owner:TOYOTA JIDOSHA KK

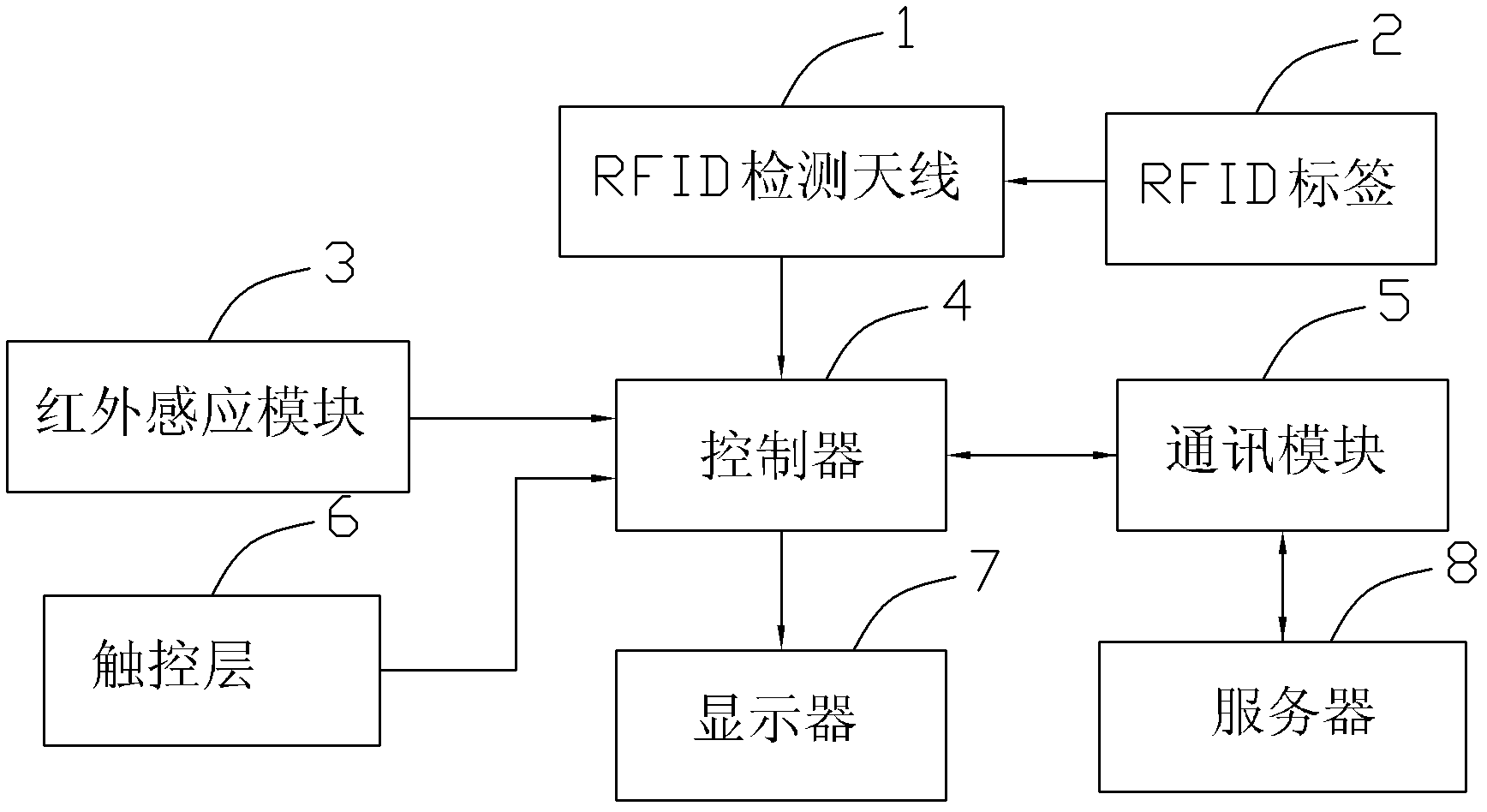

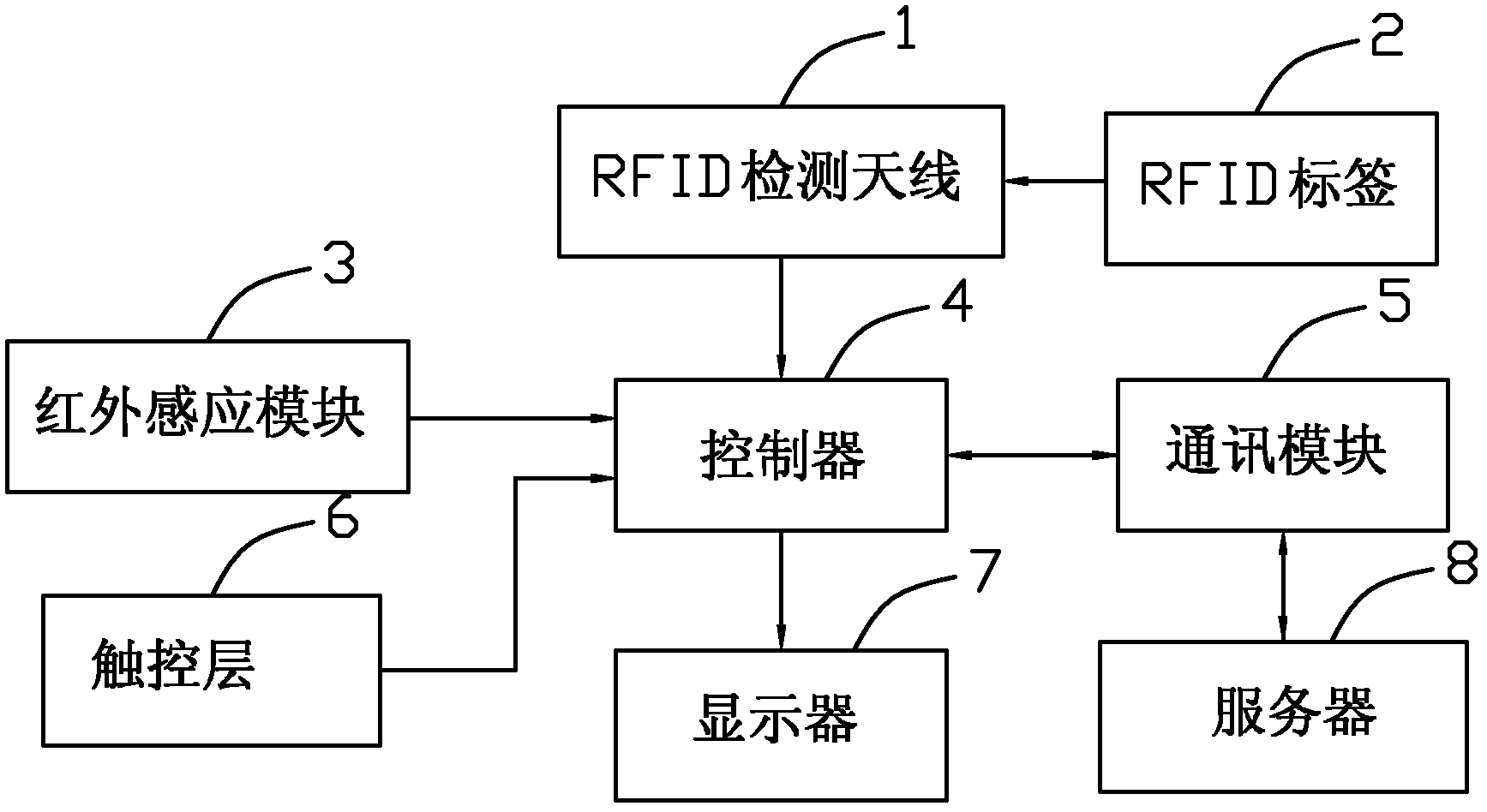

Intelligent mirror touch-control display system

InactiveCN102306075ADisplay richHas functions; the present invention can utilize the touch layer to realize human-computer interactionSpecial data processing applicationsInput/output processes for data processingControl layerDisplay device

Owner:厦门市鼎朔信息技术有限公司

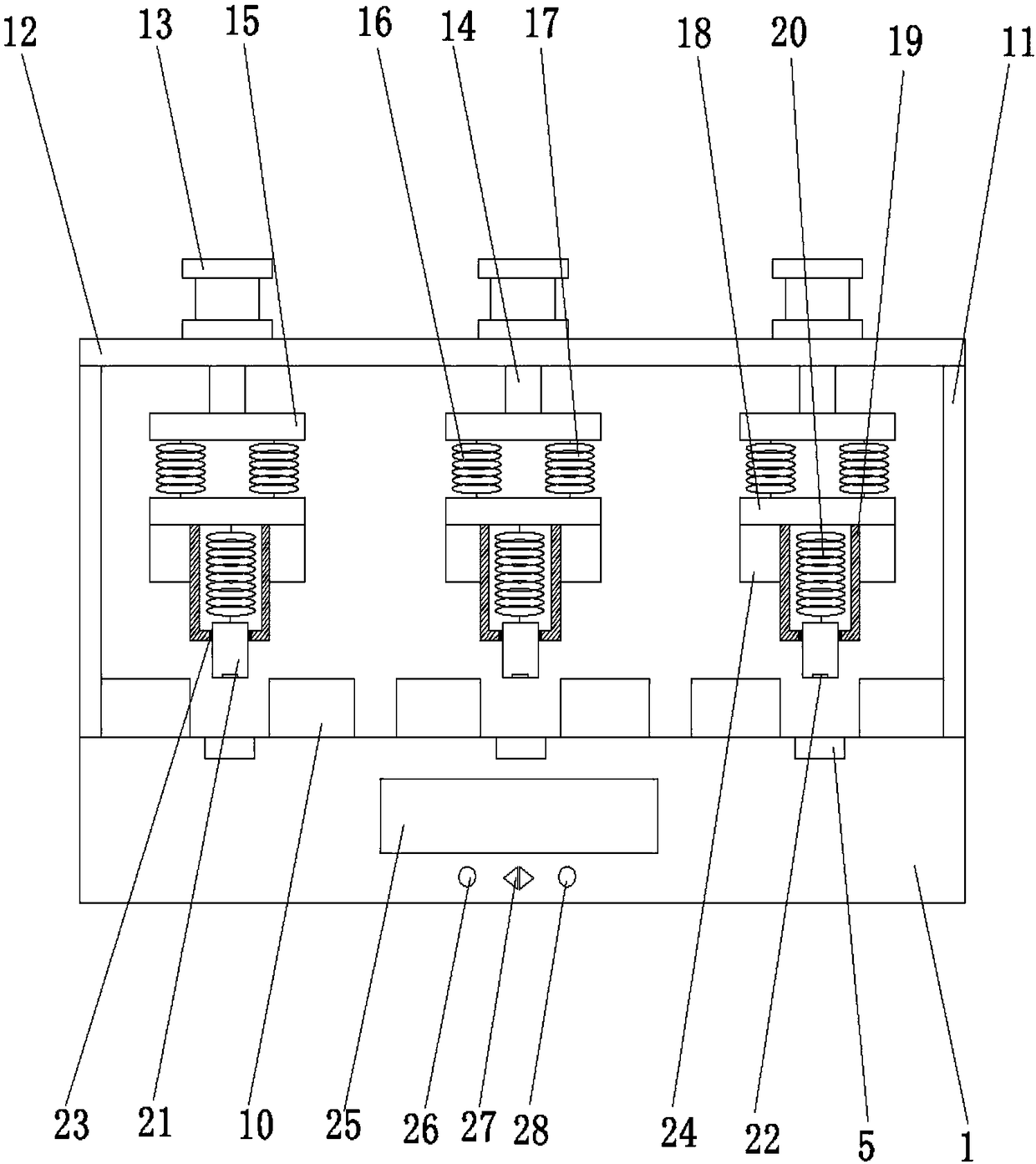

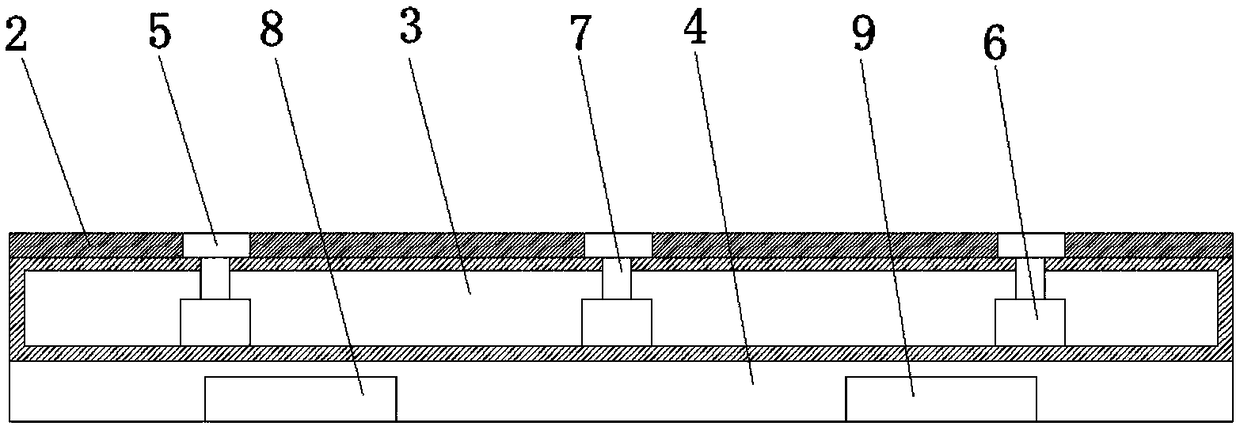

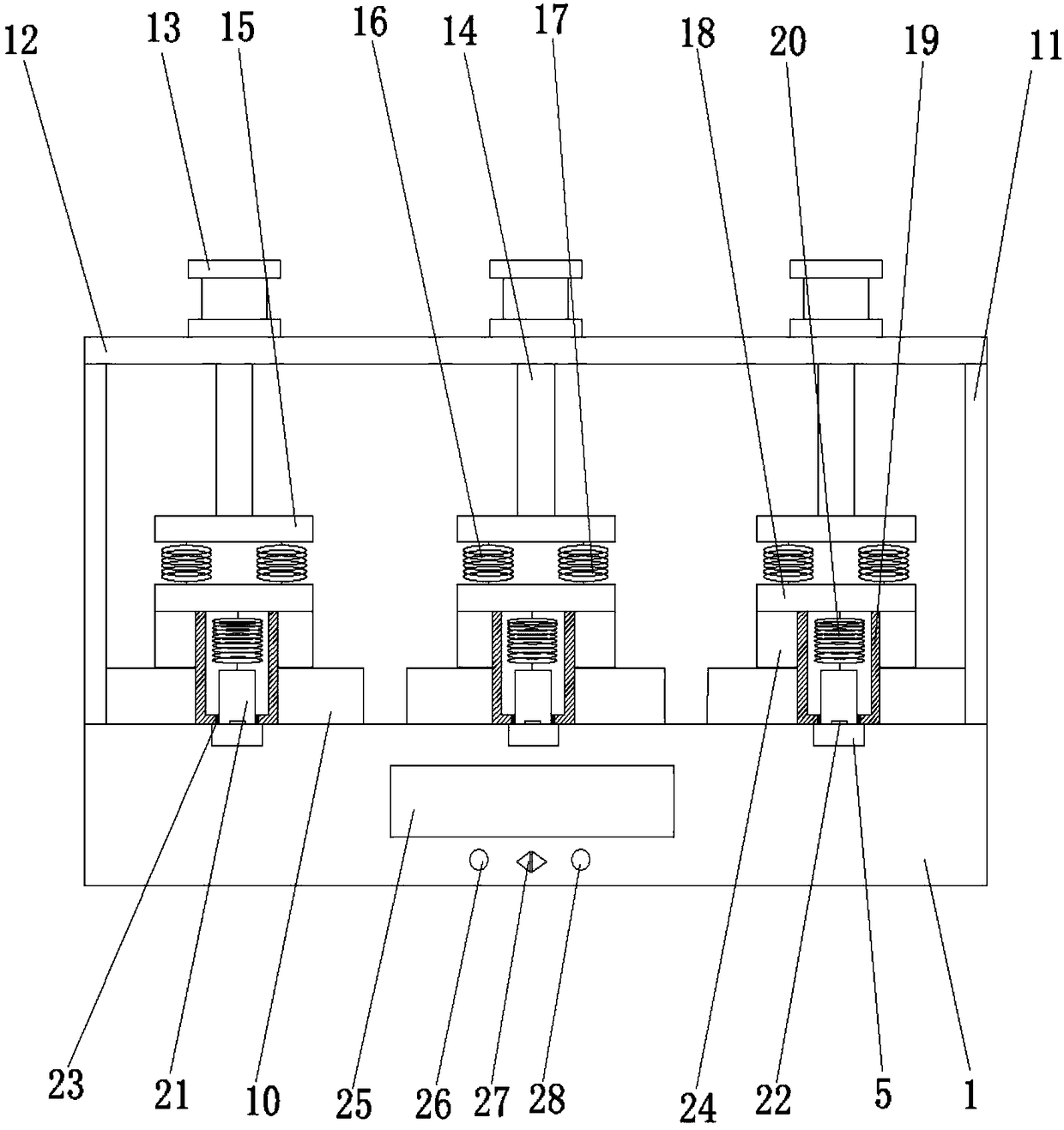

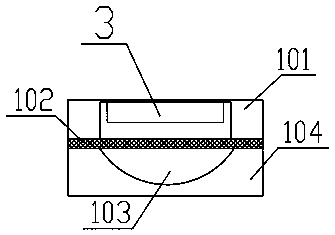

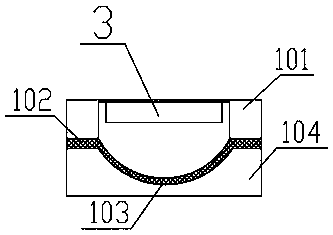

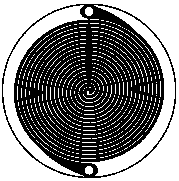

On-batch pressing testing device for touch control chip

InactiveCN108362565AGuaranteed accuracyDoes not affect accuracyMaterial strength using tensile/compressive forcesTest efficiencyControl layer

Owner:HUZHOU HUINENG ELECTROMECHANICAL TECH CO LTD

Microfluidic chip and microfluidic drive and control system thereof

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

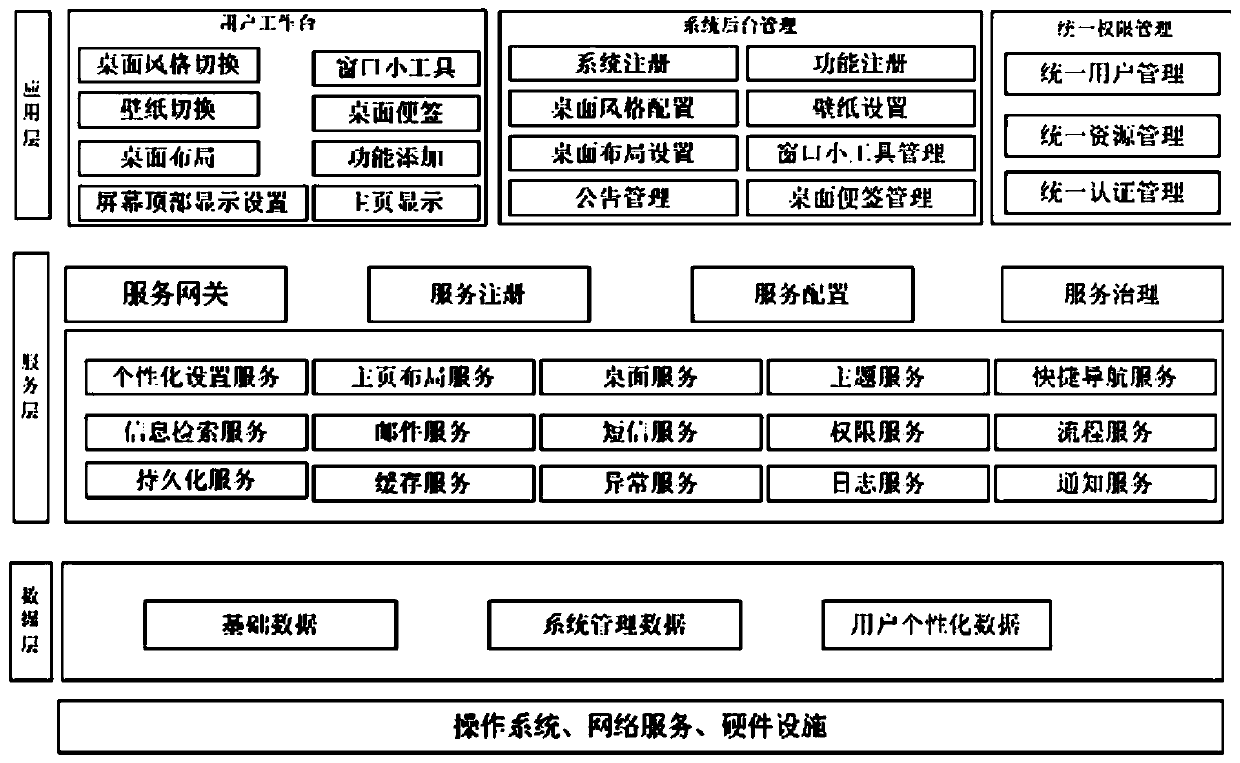

Web version mobile phone desktop system based on micro-service application architecture and user workbench

PendingCN111026372AThe operation steps link is shortImprove experienceSoftware designPersonalizationControl layer

Owner:BEIJING CHINA POWER INFORMATION TECH +2

Laser programming write-in device and method for magnetoresistive device

ActiveCN113029208ARealize high-precision laser writing programmingImprove manufacturing defectsManufacture of electrical instrumentsRecord information storageControl layerMaterials science

The embodiment of the invention discloses a laser programming write-in device and method for a magnetoresistive device. The device comprises a substrate, a magnetoresistive sensor and a thermal control layer which are stacked in sequence, wherein a non-magnetic insulating layer used for electrical isolation is arranged between the magnetoresistive sensor and the thermal control layer, the magnetoresistive sensor is composed of magnetoresistive sensing units, the magnetic resistance sensing unit is of a multi-layer thin film stacking structure with an antiferromagnetic layer; the laser programming write-in device is used for changing film layer parameters of the thermal control layer and / or the magnetoresistive sensor in the laser programming write-in stage so as to adjust the change rate of the temperature of the magnetoresistive sensor along with the laser power, and the temperature written into the magnetoresistive sensor at the same laser power is increased or decreased; the film layer parameters comprise at least one of a film layer material and a film layer thickness. According to the method, high-precision laser writing programming of the magnetoresistive sensor is realized, manufacturing defects of the magnetoresistive sensor are improved, the performance of the magnetoresistive sensor is improved, and detection precision of the magnetoresistive sensor is further improved.

Owner:MULTIDIMENSION TECH CO LTD

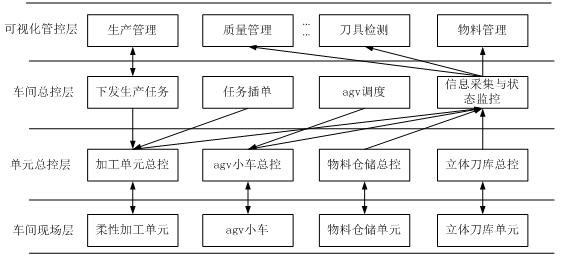

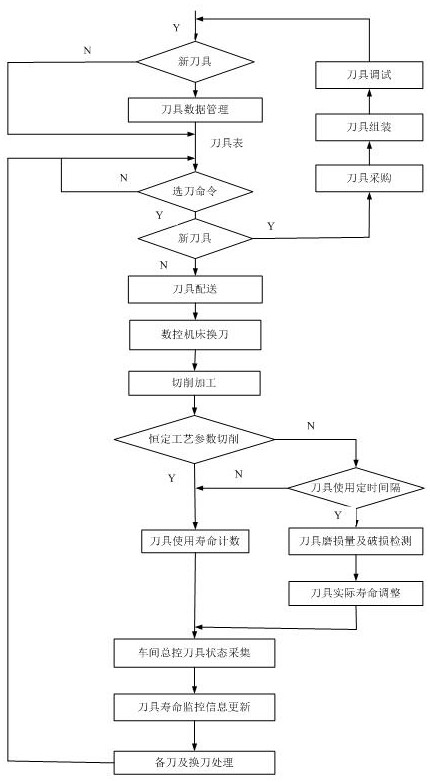

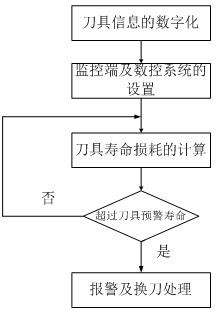

Intelligent monitoring system and method for service life of cutter

PendingCN113721575ATraceableFully grasp management informationTotal factory controlProgramme total factory controlControl layerOriginal data

Owner:SHENYANG INST OF TECH

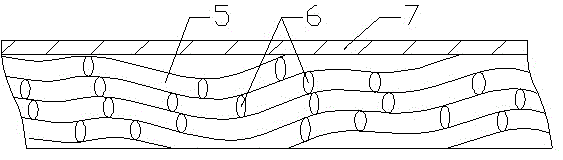

Non-slip slightly-fragrant bag

Owner:梅建熙

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap