Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Electromotive force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromotive force, abbreviated emf (denoted E and measured in volts), is the electrical action produced by a non-electrical source. A device that converts other forms of energy into electrical energy (a "transducer"), such as a battery (converting chemical energy) or generator (converting mechanical energy), provides an emf as its output. Sometimes an analogy to water "pressure" is used to describe electromotive force.

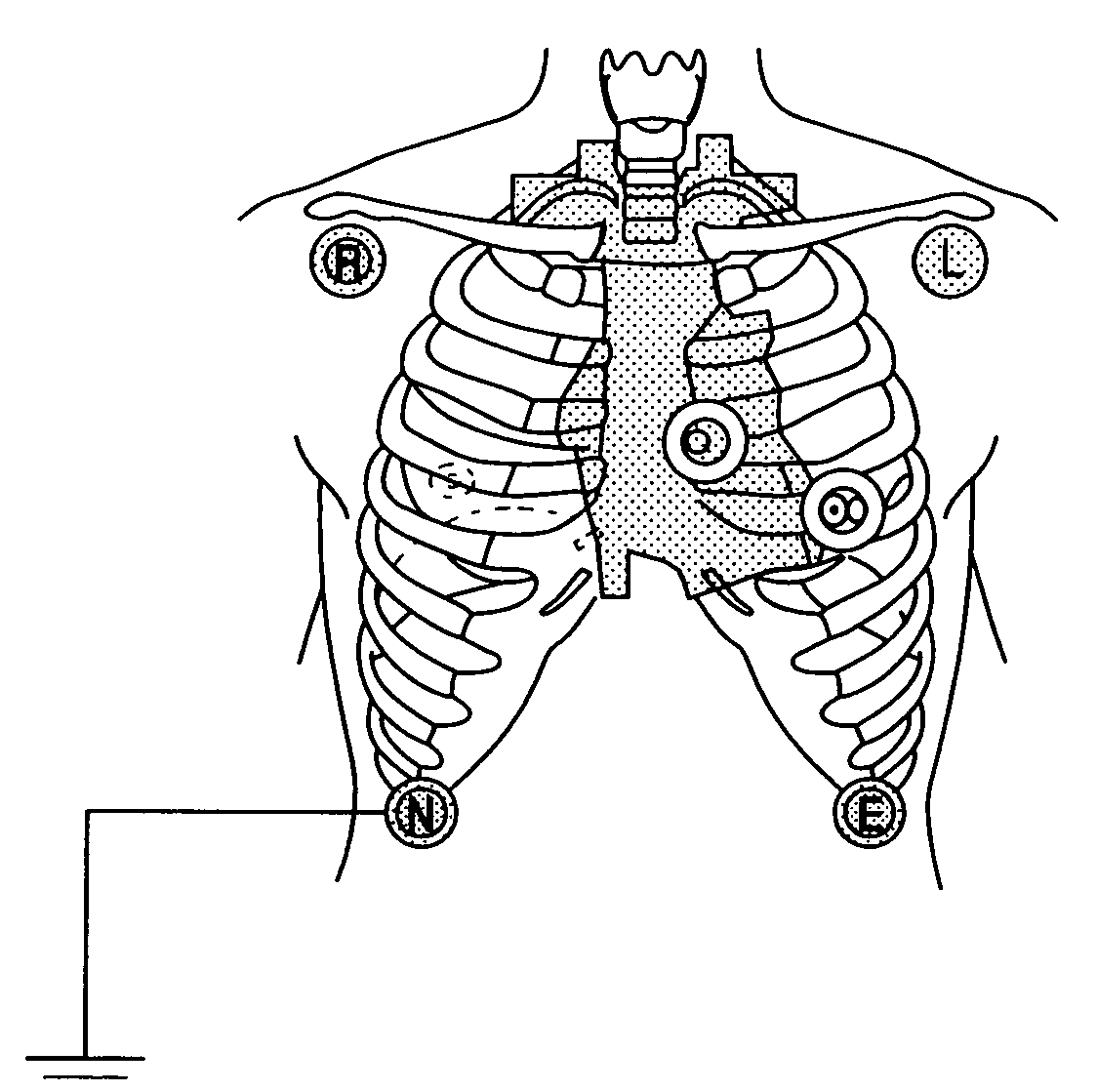

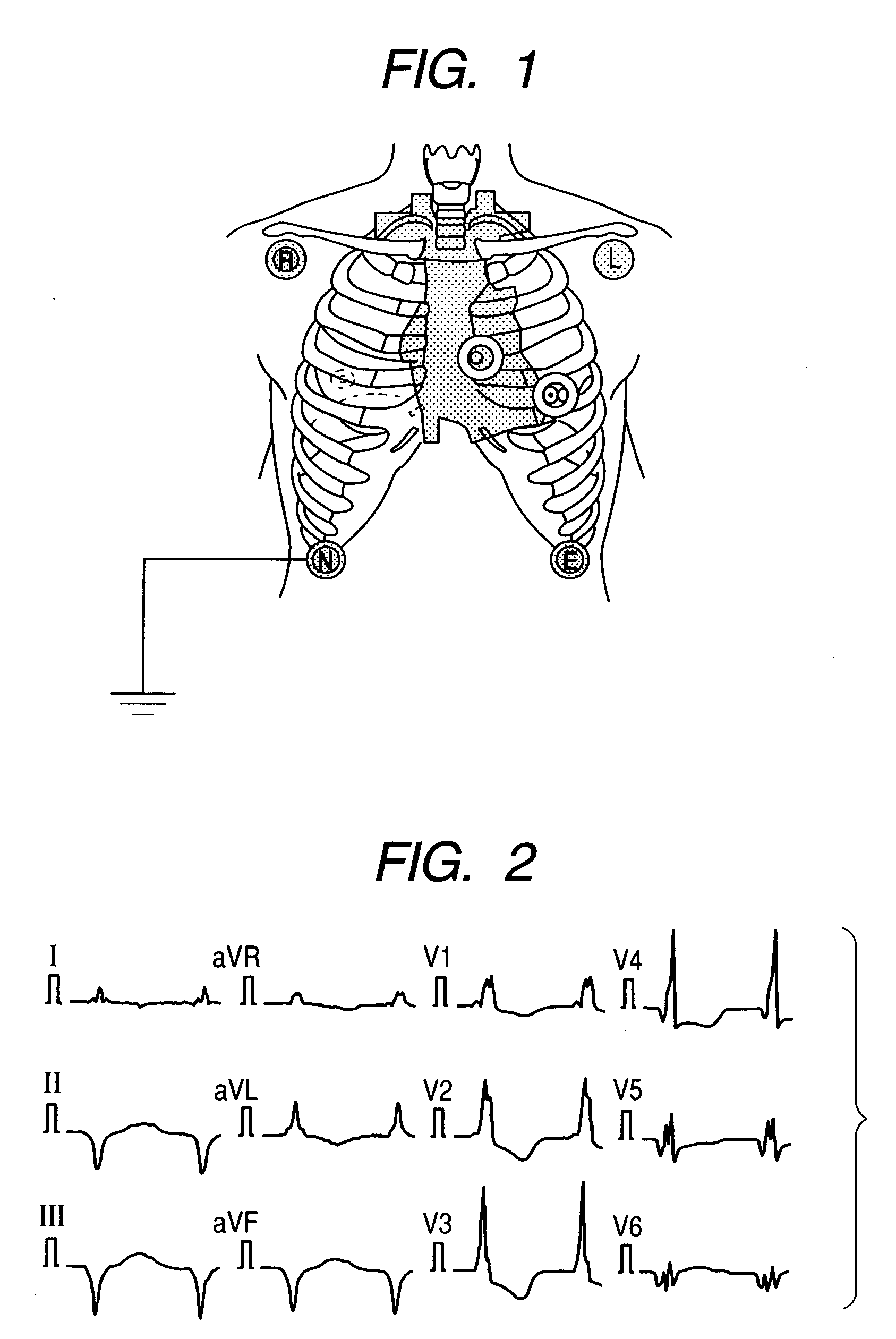

Method for deriving standard 12-lead electrocardiogram, and monitoring apparatus using the same

ActiveUS20060047212A1Improve accuracyEasily and effectively attainingElectrocardiographySensorsData setLeft anterior axillary line

Owner:NIHON KOHDEN CORP

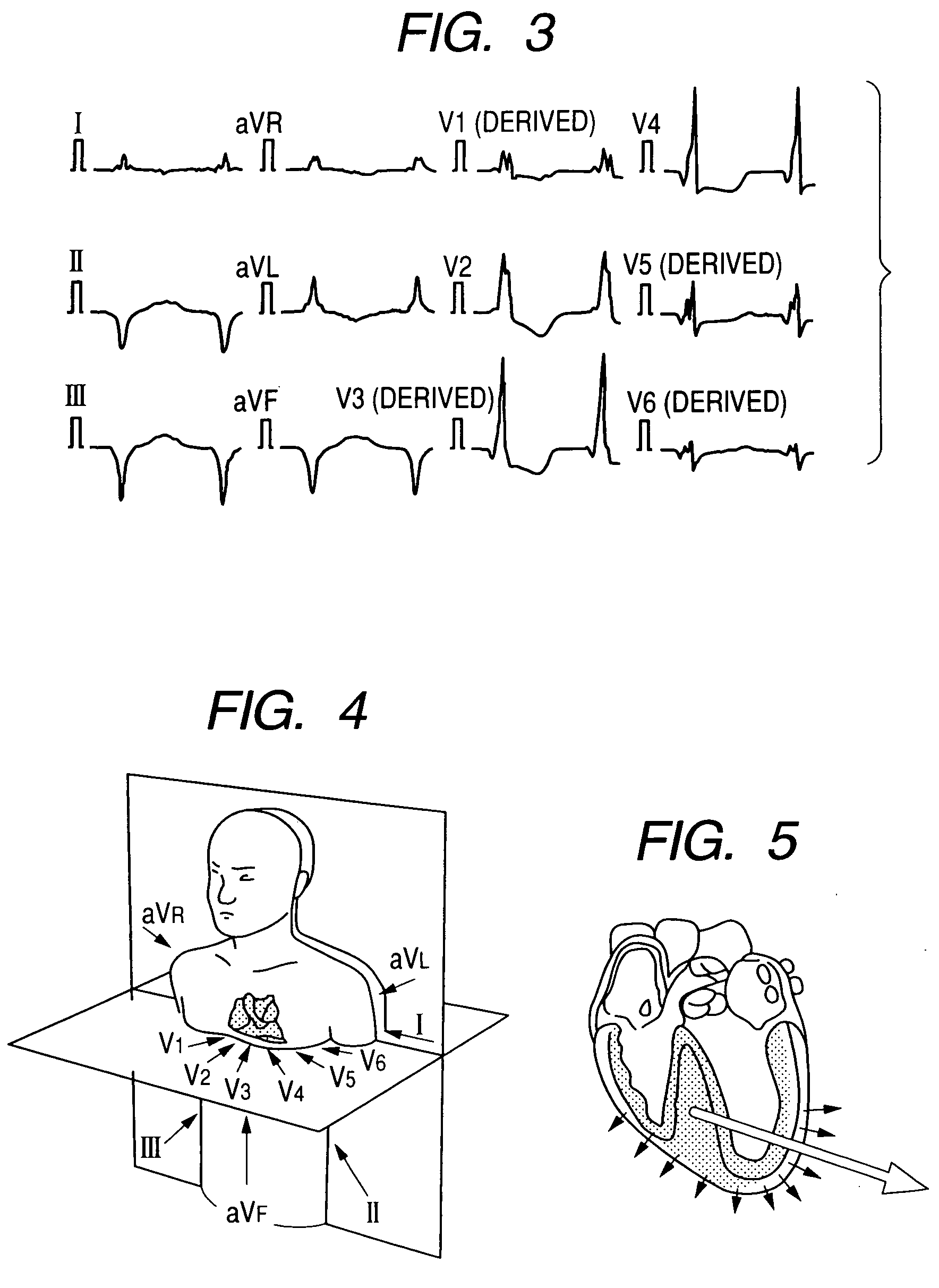

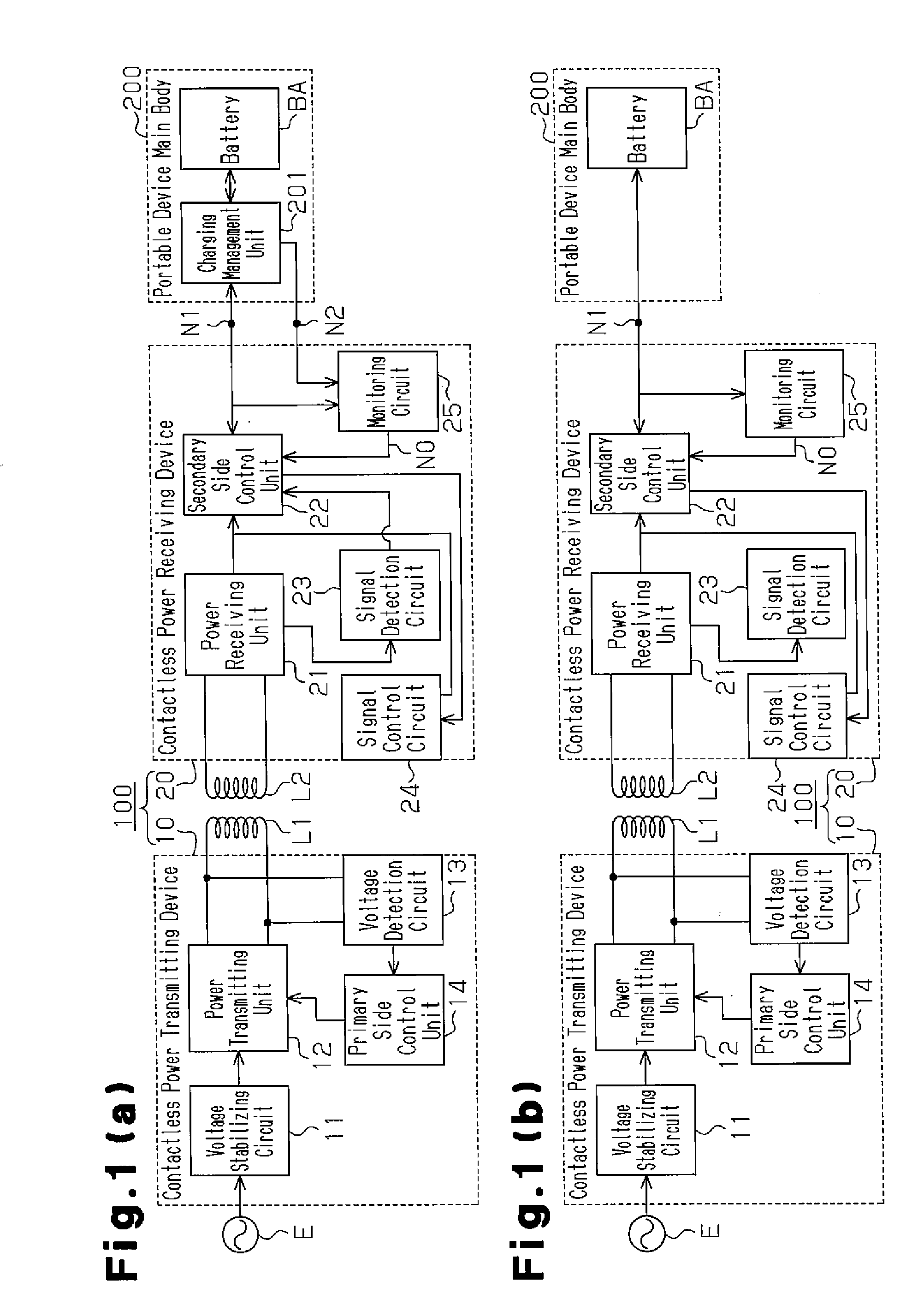

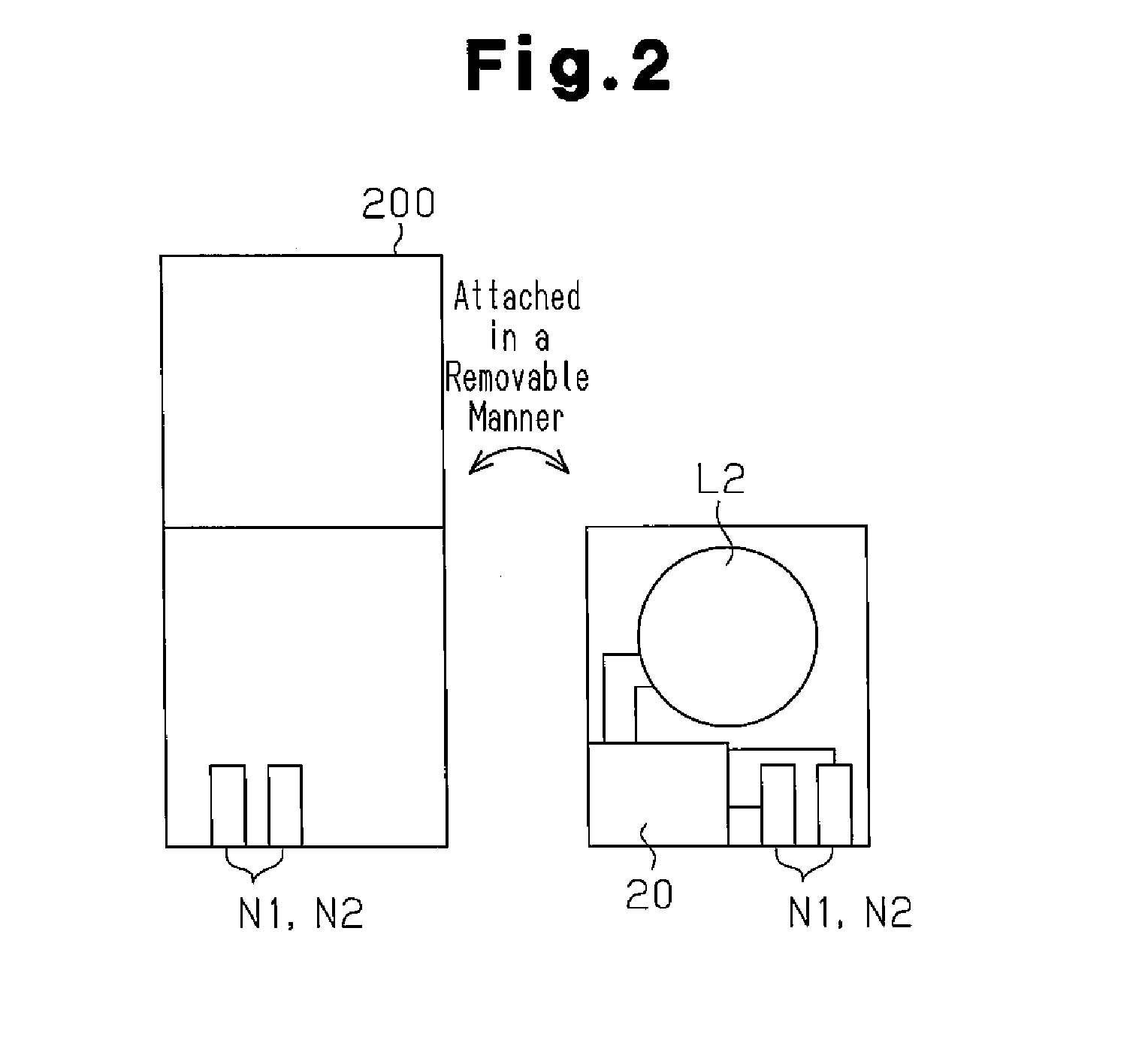

Contactless power receiving device, and contactless charging system

InactiveUS20120326661A1Circuit authenticationSecondary cells charging/dischargingElectricityElectric force

Owner:PANASONIC CORP

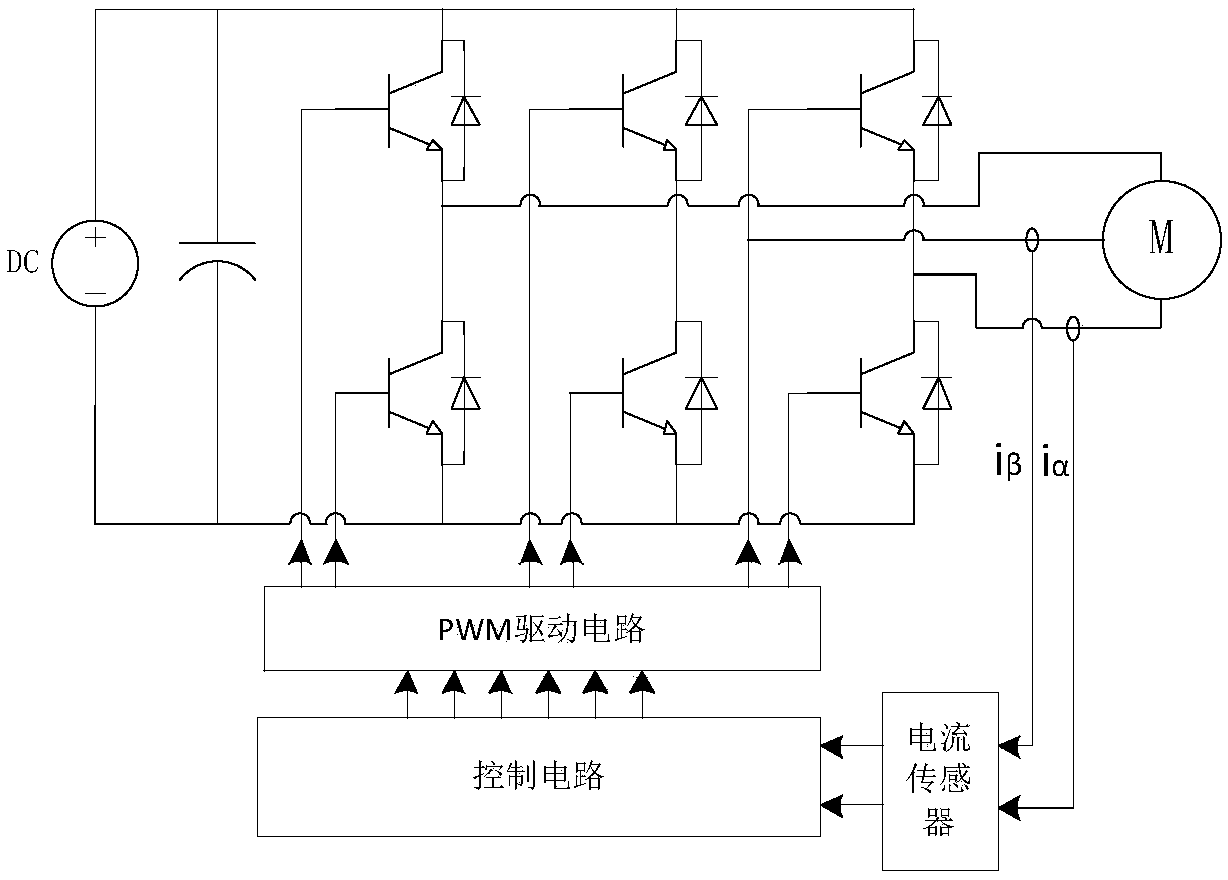

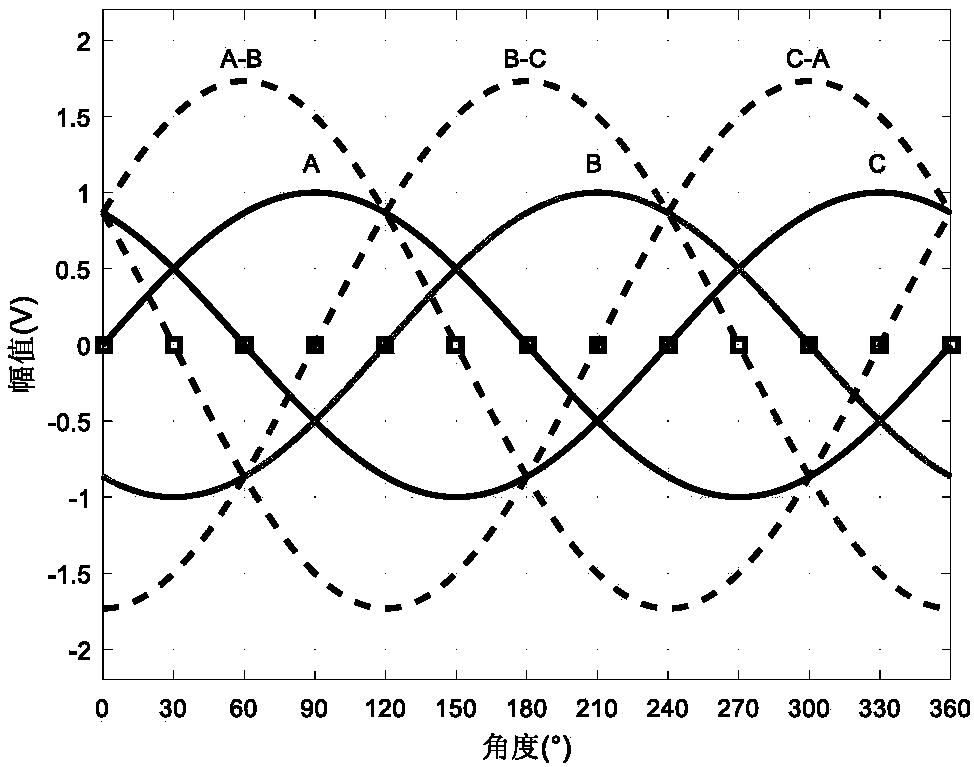

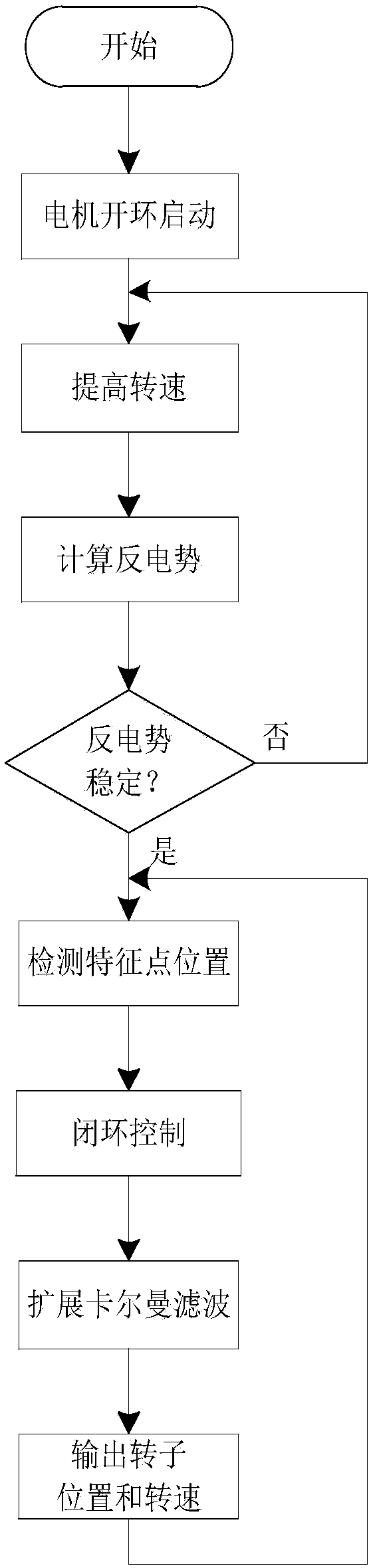

Method for detecting position of rotor of PMSM (permanent magnet synchronous motor) without position sensor

ActiveCN107769636AEasy to implementLow costElectronic commutation motor controlVector control systemsPermanent magnet synchronous motorEngineering

Owner:NORTHWESTERN POLYTECHNICAL UNIV

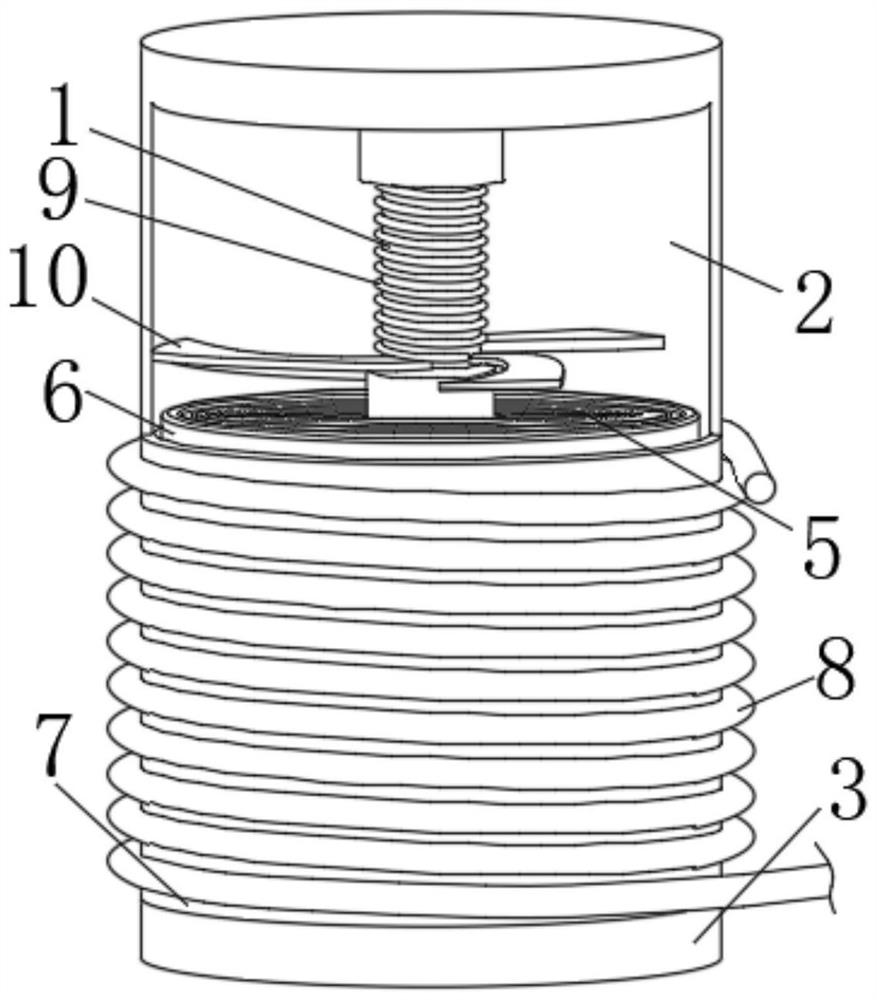

Vacuum capacitor capable of changing capacitance

PendingCN113764188AChange capacityHigh positioning accuracyCapacitor with electrode area variationCapacitanceElectromotive force

Owner:上海华盈实科技有限公司

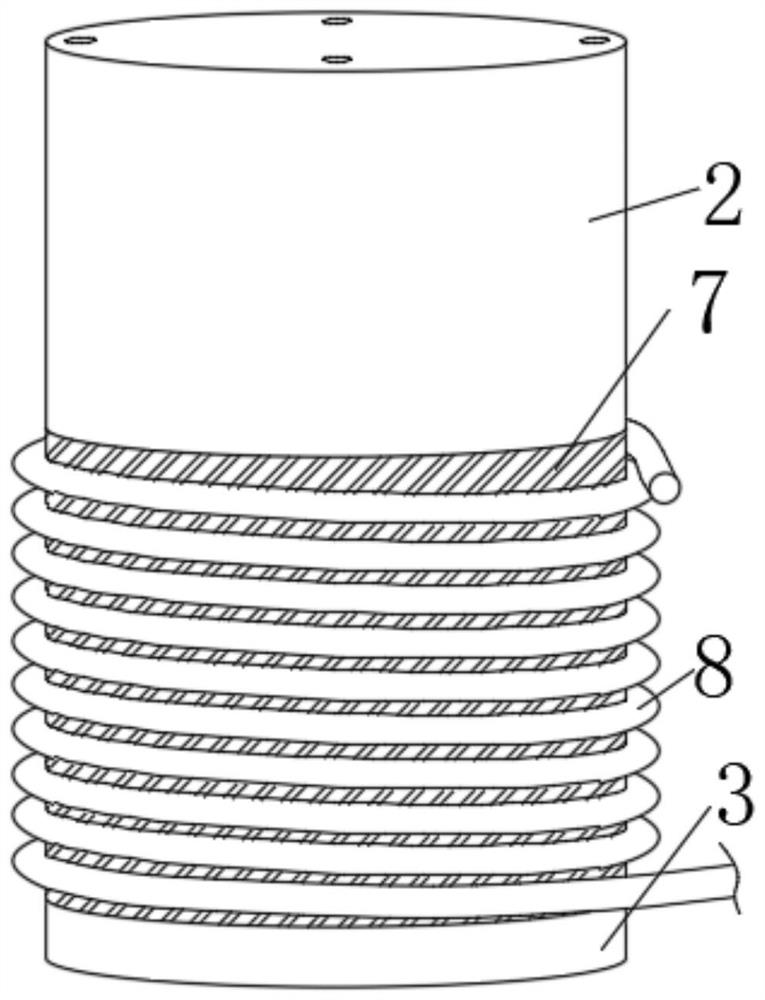

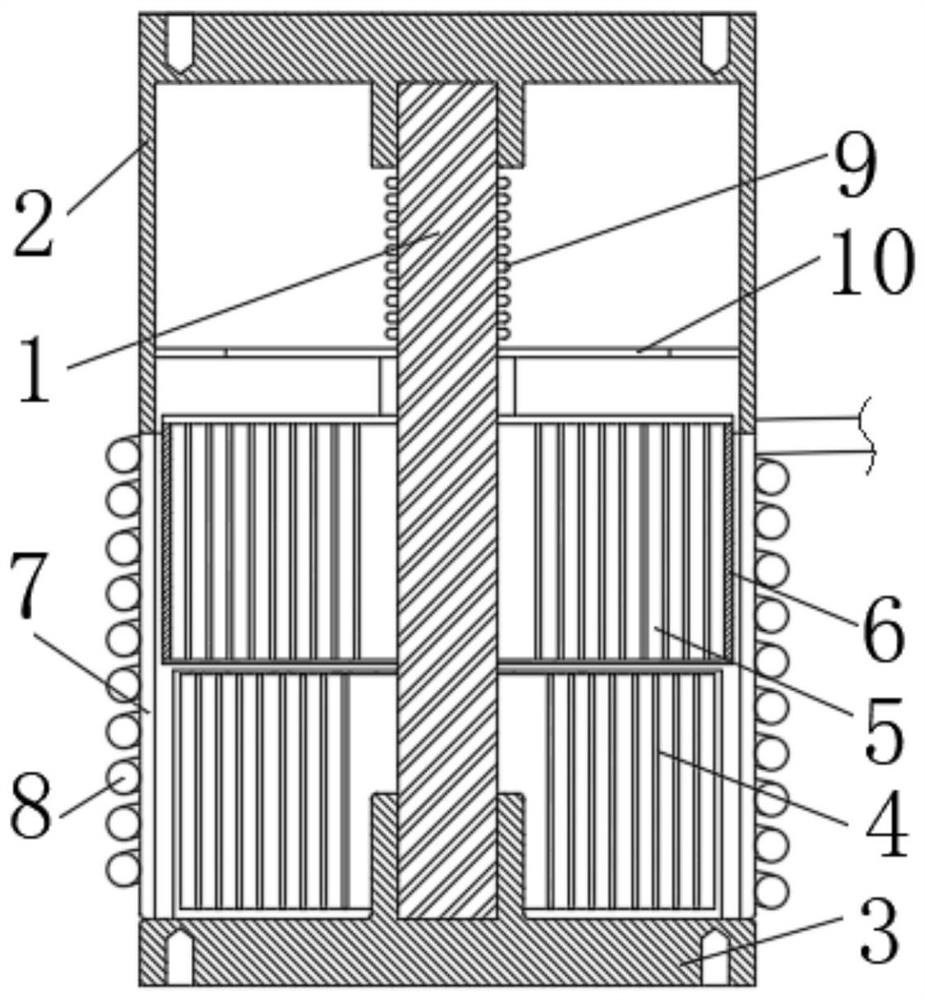

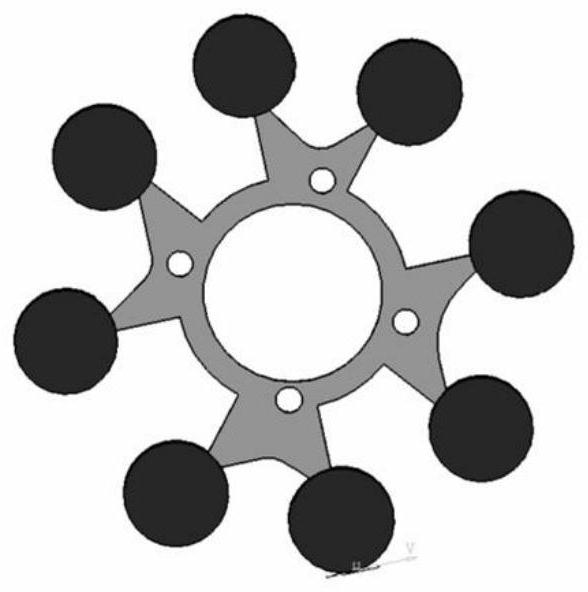

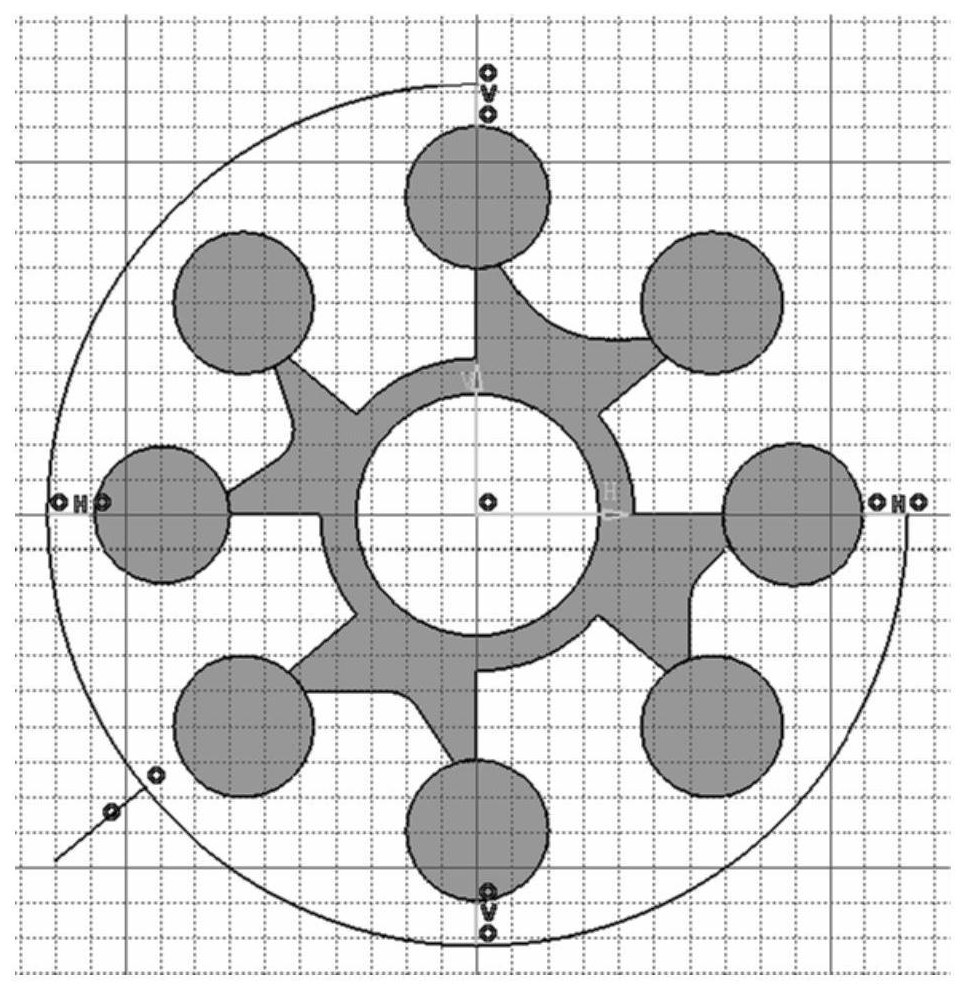

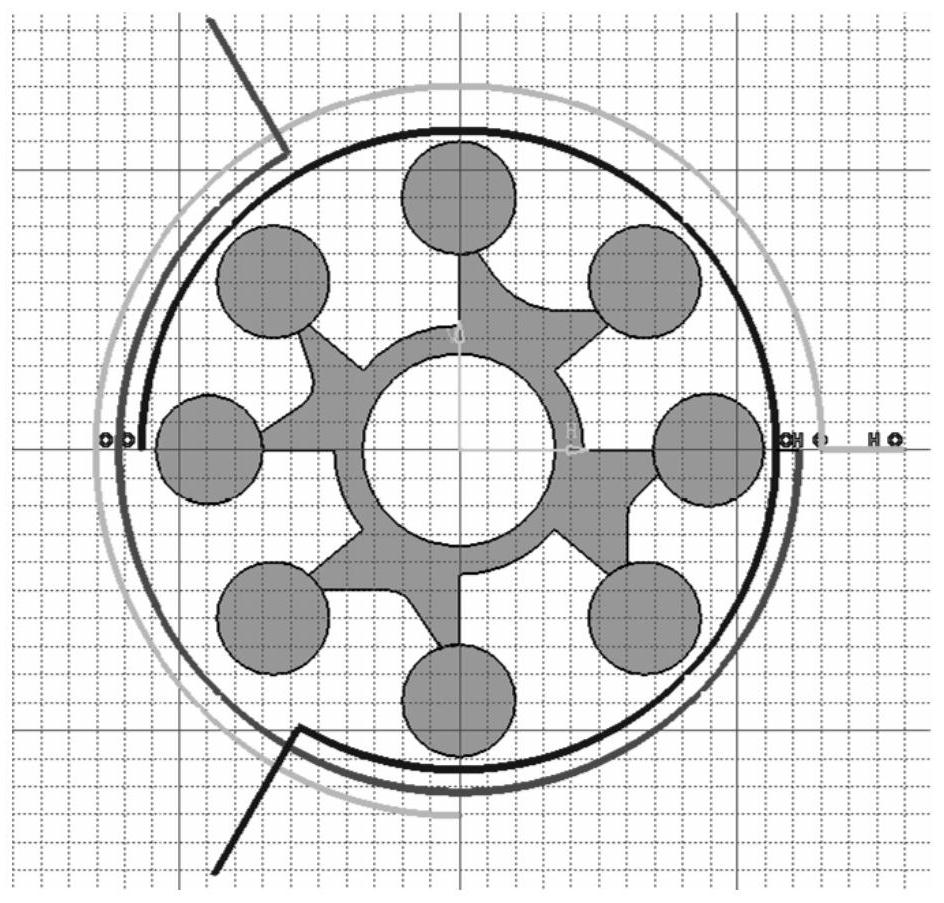

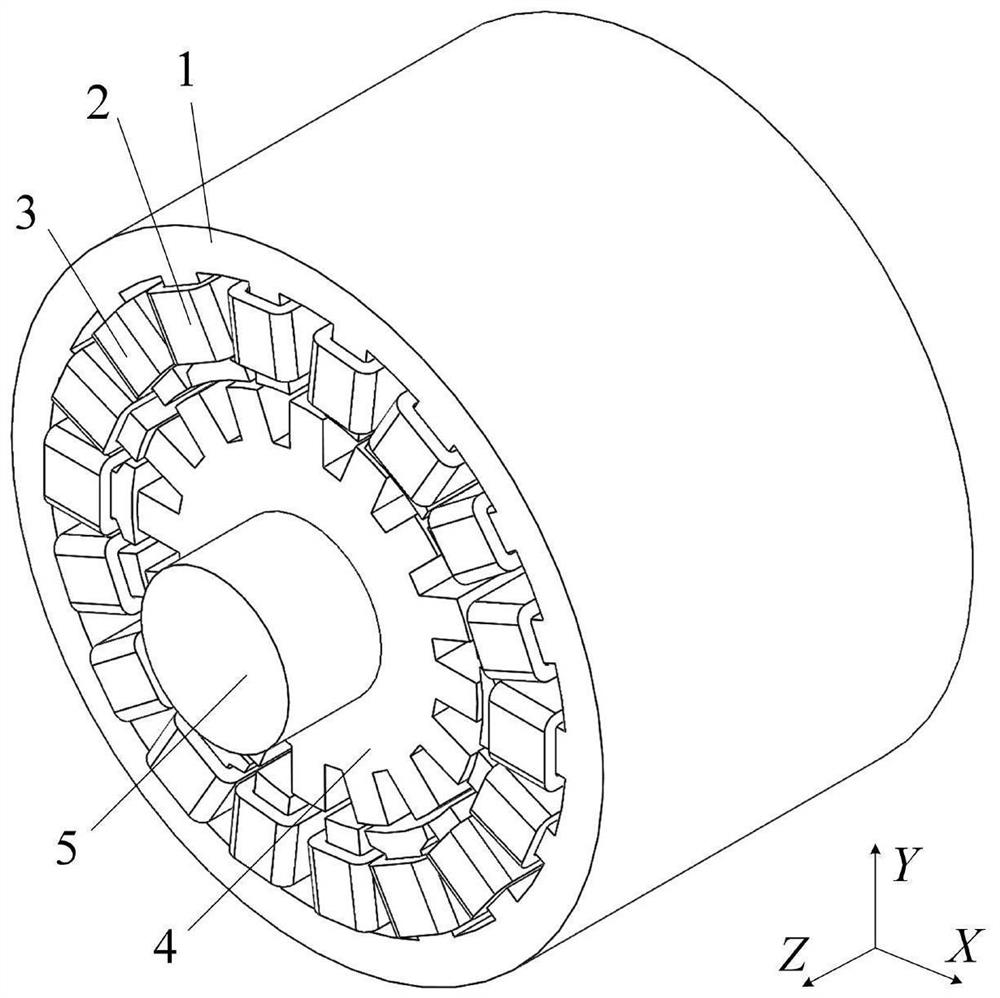

Double high axial motor capable of effectively reducing back electromotive force torque ripple

PendingCN113541427AReduce back EMFIncrease torqueMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsElectrical resistance and conductanceElectric machine

Owner:CHONGQING WANGJIANG IND

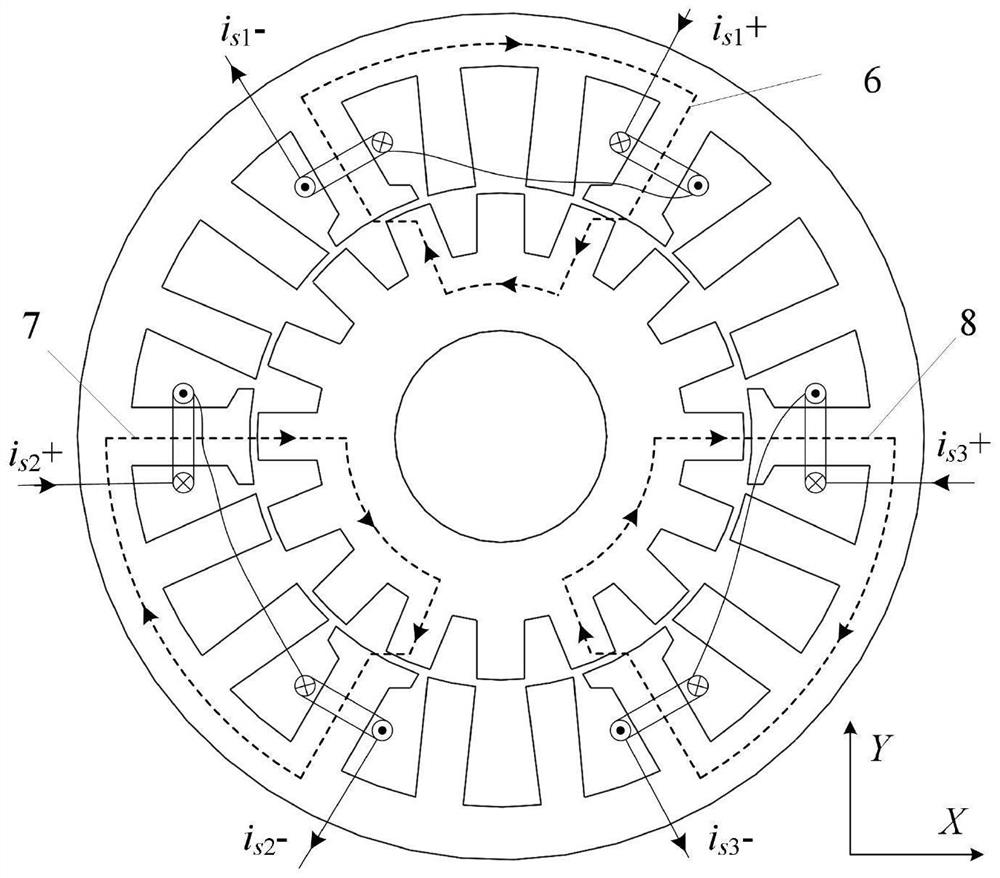

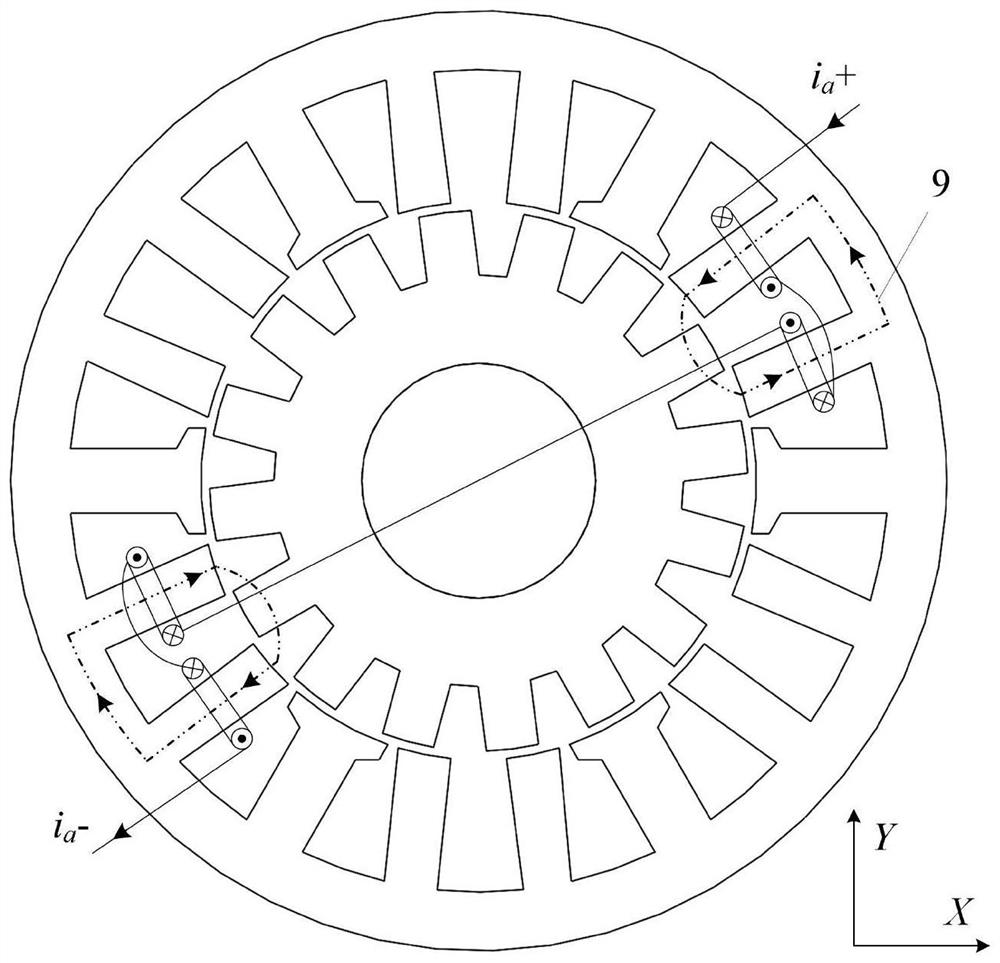

Three-phase 18/16-pole bearingless switched reluctance motor

ActiveCN113162316AEasy to controlSimple structureElectric machinesMechanical energy handlingMagnetic bearingMagnetic reluctance

Owner:NANJING UNIV OF POSTS & TELECOMM

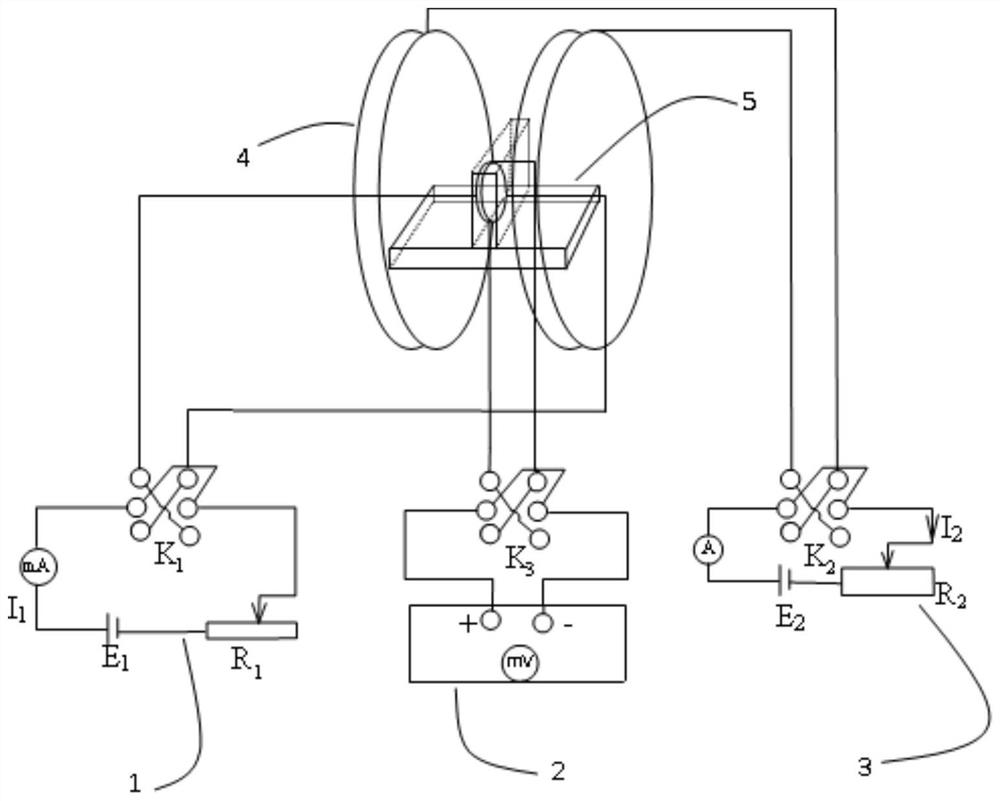

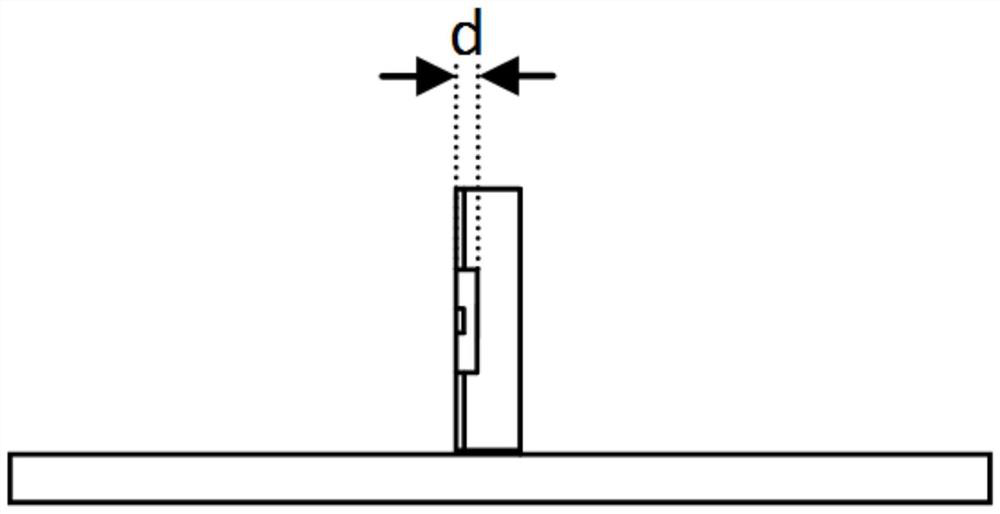

Device for rapidly judging conductivity type of metal mineral powder material

PendingCN114113963AQuick judgmentEffective judgmentIndividual semiconductor device testingHelmholtz coilHemt circuits

Owner:KUNMING UNIV OF SCI & TECH

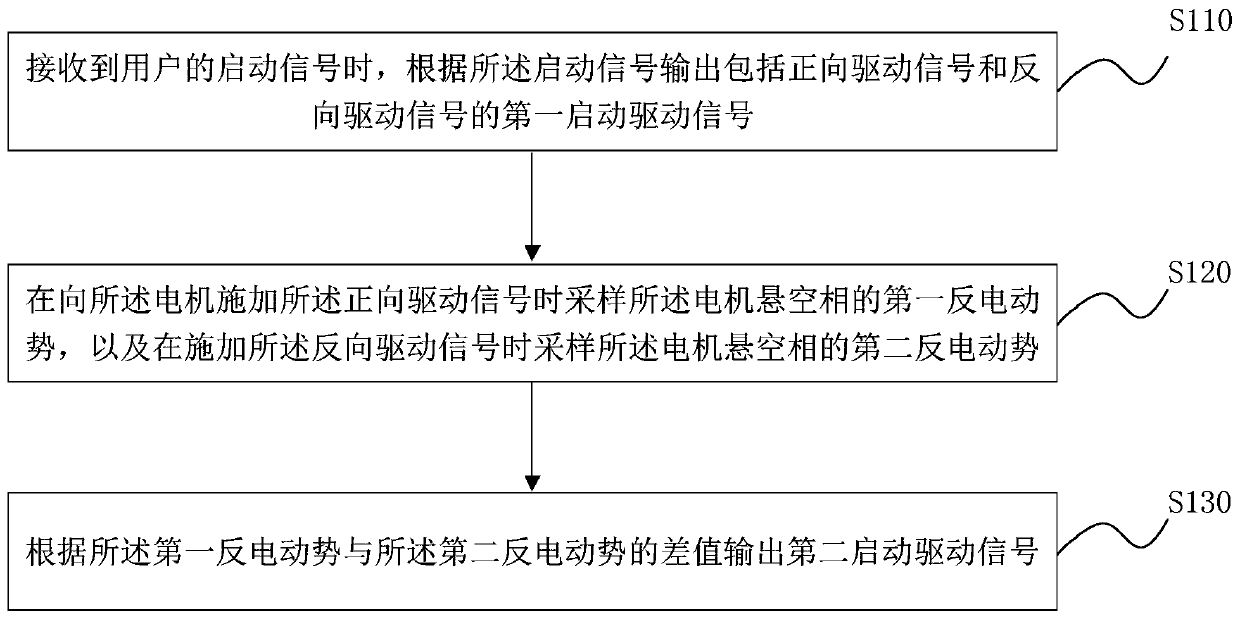

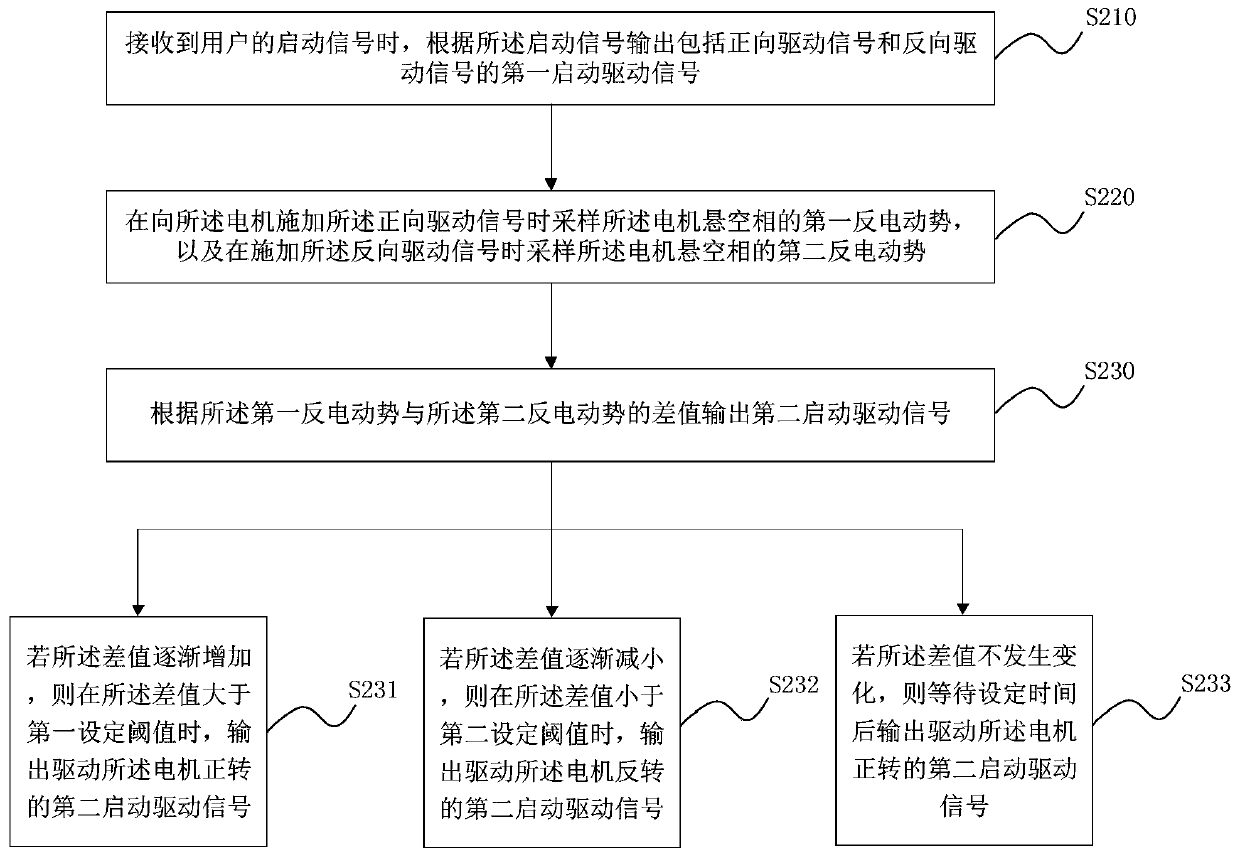

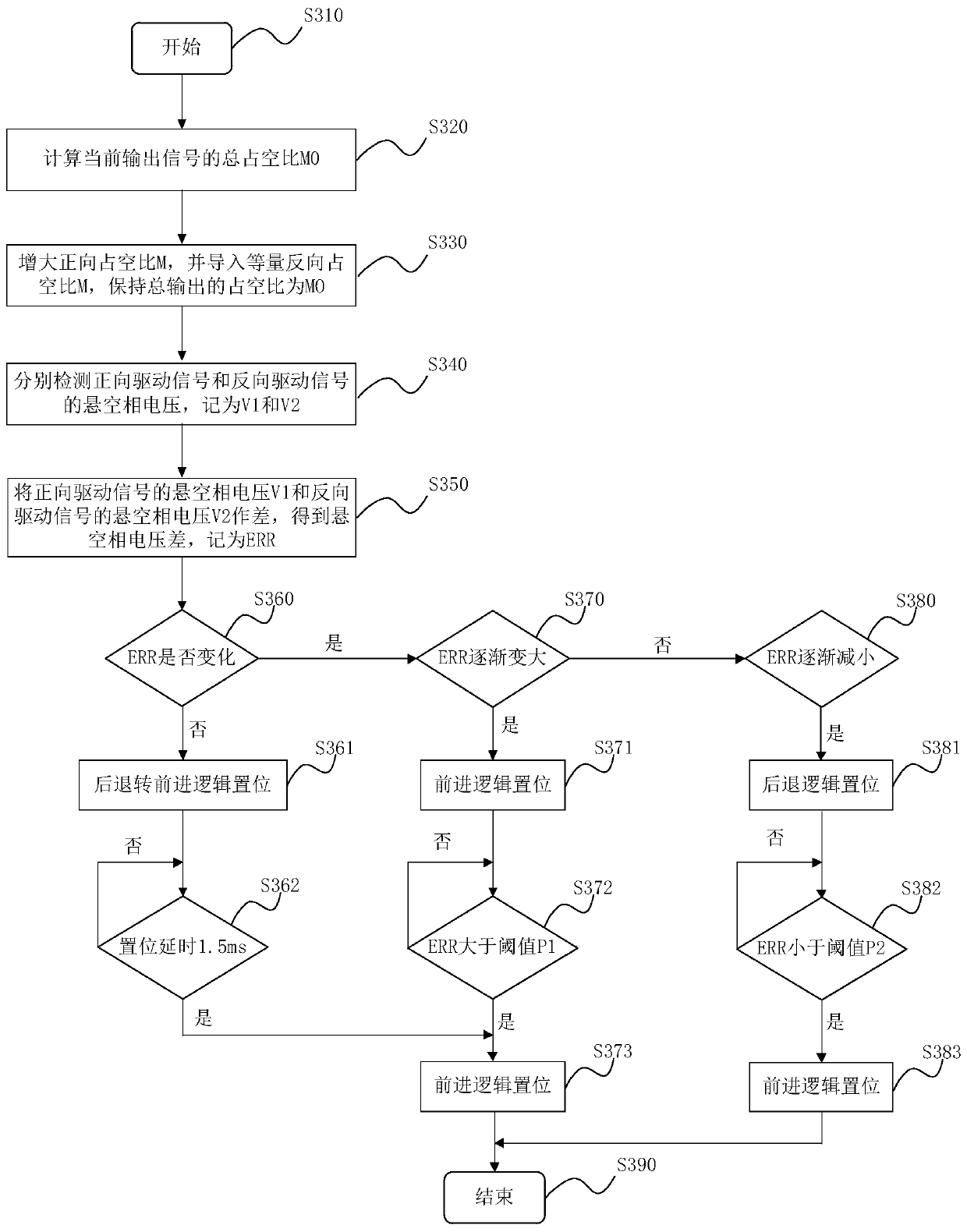

Electric vehicle control method and electric vehicle controller

ActiveCN110752803AReduce noiseSolve the problem of out-of-controlSpeed controllerElectric machinesElectric machineryElectric cars

Owner:GUANGDONG GOBAO ELECTRONICS TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap