Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Inlet temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inlet temperature. The temperature signal taken in the engine inlet to measure air density and sent to the fuel control unit as a fuel-scheduling parameter.

Method of chilling inlet air for gas turbines

InactiveUS20050056023A1Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersPower stationCooling coil

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

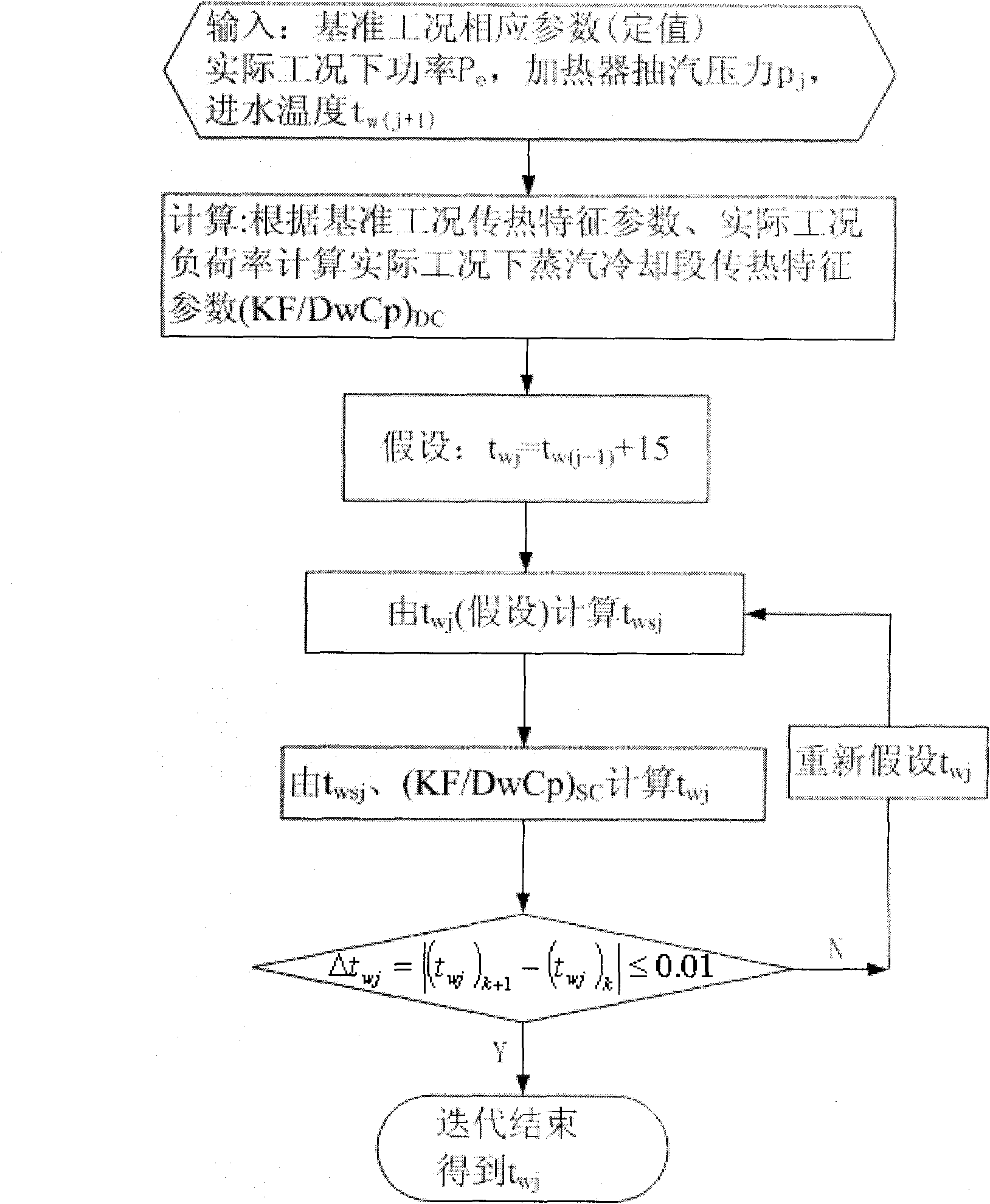

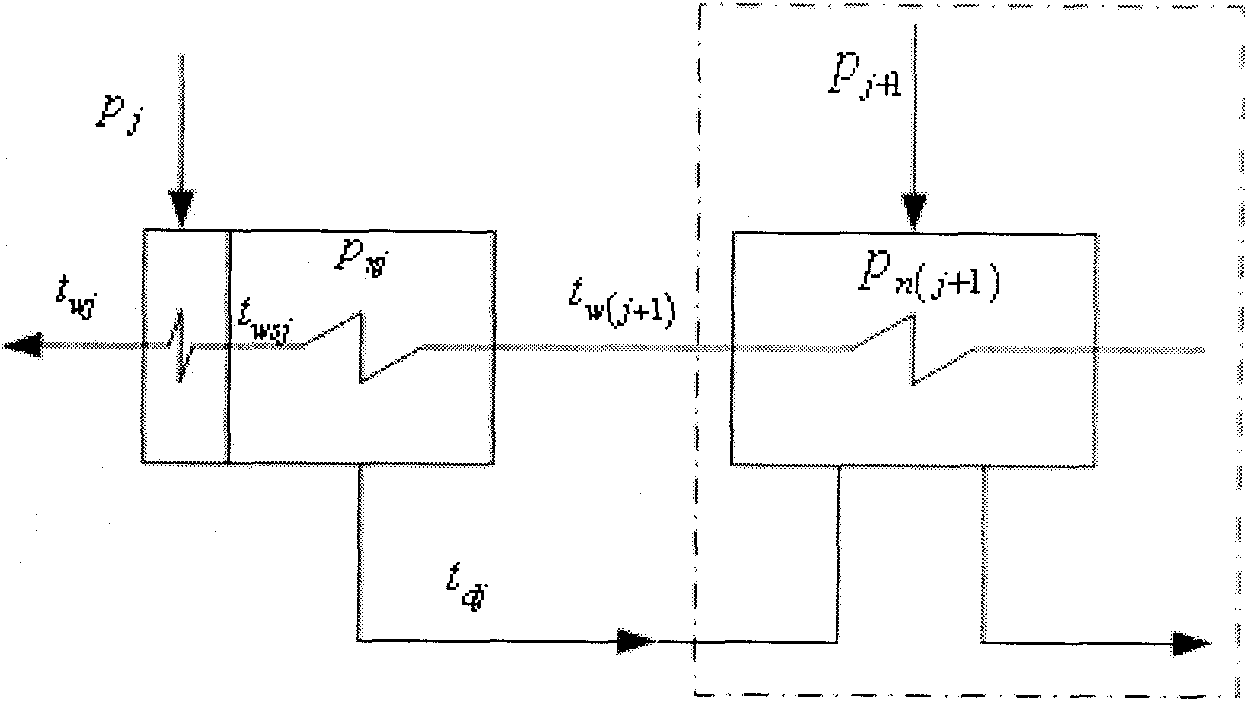

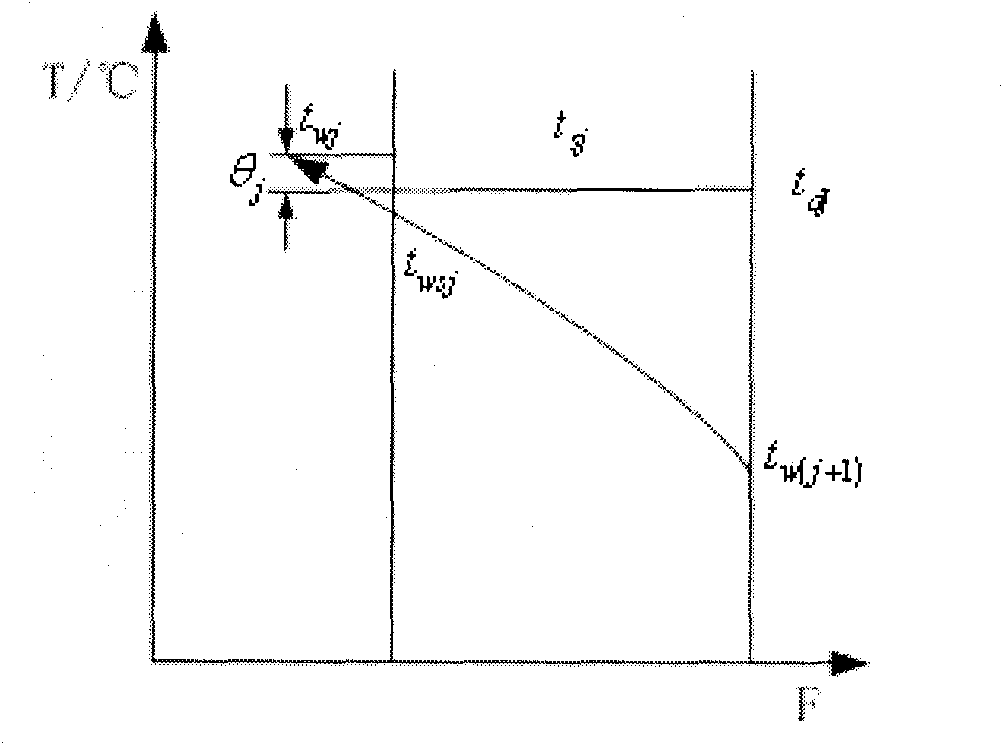

Method for measuring temperatures of out-flowing water and discharged water of heater of turbine steam cooler

Owner:SOUTHEAST UNIV

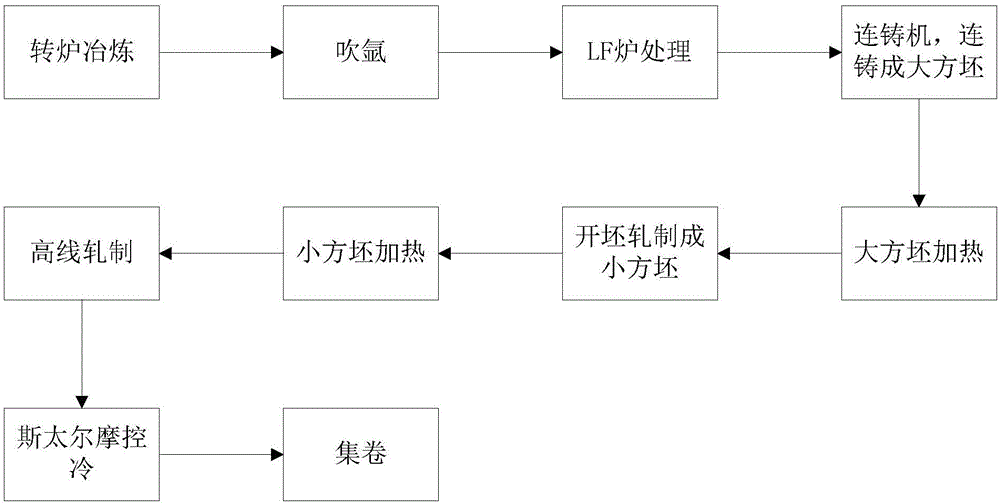

Method for relieving pattern segregation of spring steel

ActiveCN106399654ASolve the problem of resentmentReduce manufacturing costTemperature differenceSpring steel

Owner:武汉钢铁有限公司

Test method and device for simulating thermal WHTC circulation in diesel hot and cold WHTC circulation

The invention discloses a test method and device for simulating thermal WHTC circulation in diesel hot and cold WHTC circulation. The test method comprises the following steps that test conditions aremet by controlling the lower air inlet temperature, air inlet vacuum degree, post-intercooling temperature and exhaust back pressure under rated conditions of a diesel engine according to rules; according to a WHTC circulation program set by a gantry, circulation conditions in the WHTC circulation program at the last 600+ / -10s are selected for testing to pre-process an SCR catalyst unit; after the SCR catalyst unit is preprocessed, diesel engine hot dipping is carried out immediately for 10+ / -1min to serve as pro-processing of a diesel engine hot start WHTC circulation test; the steps of a formal thermal WHTC circulation test involve that a gantry WHTC circulation program is started immediately after a hot dipping period is completed for the formal thermal WHTC circulation test, thereforethe temperature of a thermal WHTC circulation SCR catalytic unit is consistent with the temperature of the thermal WHTC circulation in the hot and cold WHTC circulation, the efficiency of the SCR catalyst unit can be fully utilized, the consumption of urea can be reduced, the energy is saved, the environment is protected, and a large amount of test time can be saved.

Owner:GUANGXI YUCHAI MASCH CO LTD

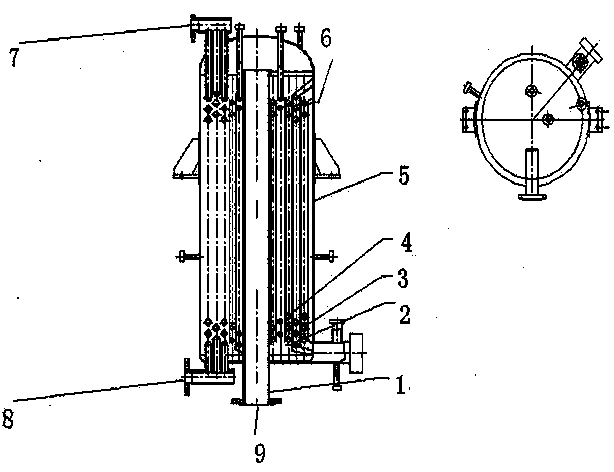

Coiler type condenser

Owner:HEILONGJIANG DAMING DAIRY MACHINERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap