Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Submerged arc welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

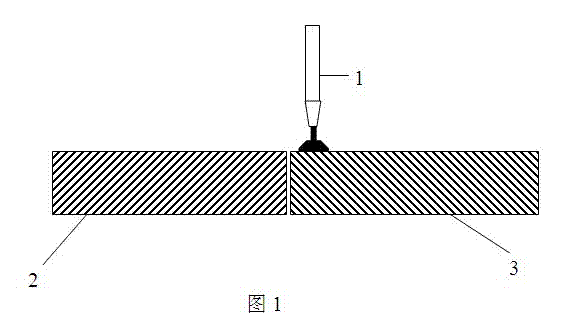

Submerged arc welding (SAW) is a common arc welding process. The first patent on the submerged-arc welding (SAW) process was taken out in 1935 and covered an electric arc beneath a bed of granulated flux. Originally developed and patented by Jones, Kennedy and Rothermund, the process requires a continuously fed consumable solid or tubular (metal cored) electrode. The molten weld and the arc zone are protected from atmospheric contamination by being "submerged" under a blanket of granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride, and other compounds. When molten, the flux becomes conductive, and provides a current path between the electrode and the work. This thick layer of flux completely covers the molten metal thus preventing spatter and sparks as well as suppressing the intense ultraviolet radiation and fumes that are a part of the shielded metal arc welding (SMAW) process.

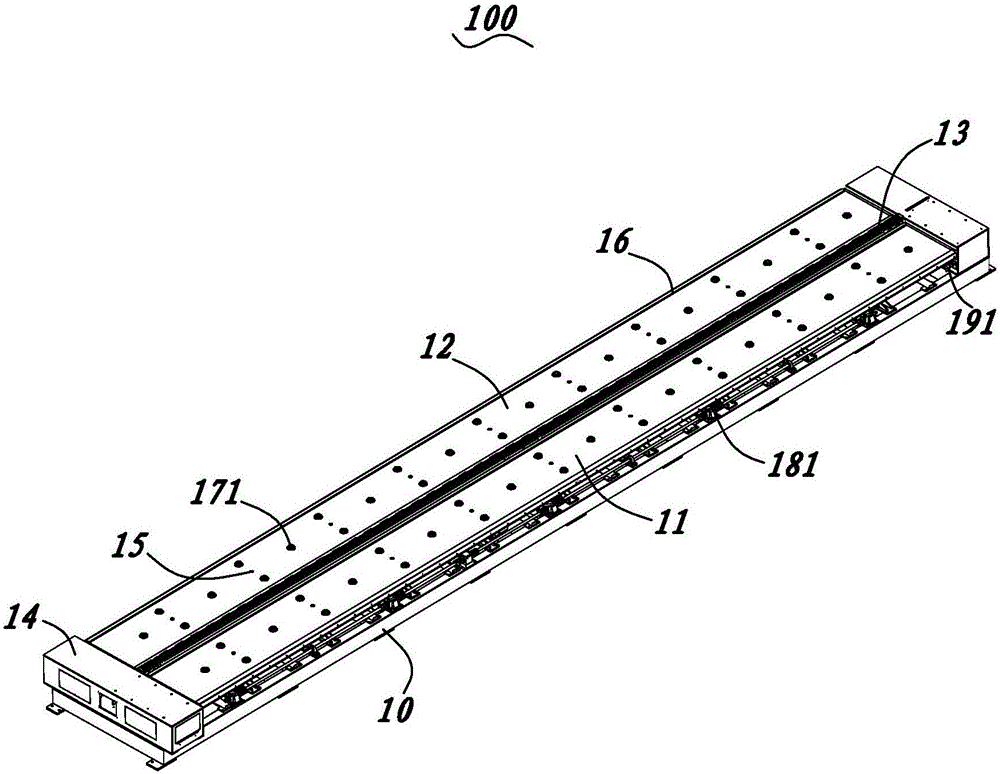

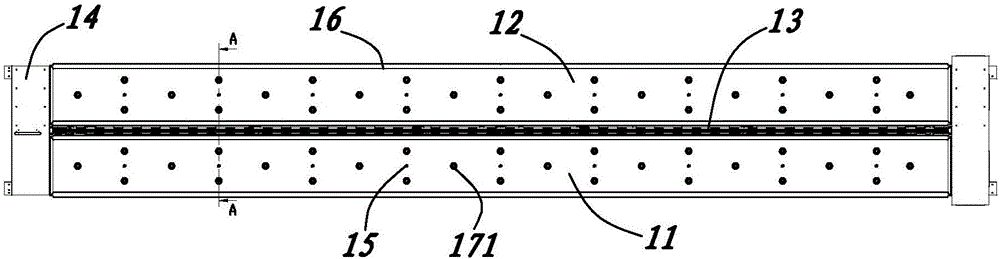

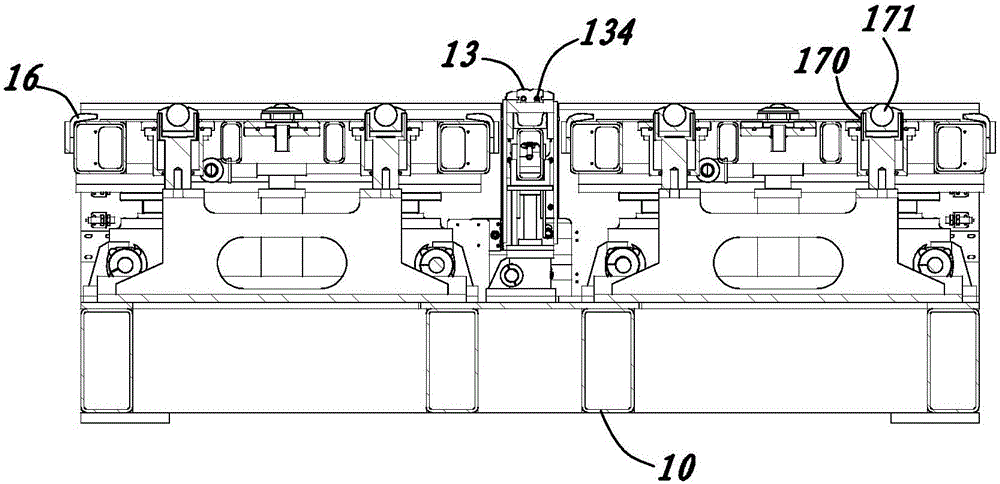

Vacuum adsorption welding device for plate splicing in submerged-arc welding

ActiveCN106077918AFast adsorption fixationEasy to operateWelding/cutting auxillary devicesArc welding apparatusEngineeringPlate fixation

Owner:HUAHENG WELDING

Welding wire of steel-copper dissimilar metal submerged-arc welding and welding method of welding wirethereof

InactiveCN102873467AImprove mechanical propertiesBeautiful shapeArc welding apparatusWelding/cutting media/materialsManganeseSpot welding

Owner:SHENYANG POLYTECHNIC UNIV +1

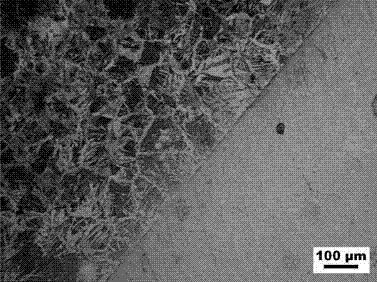

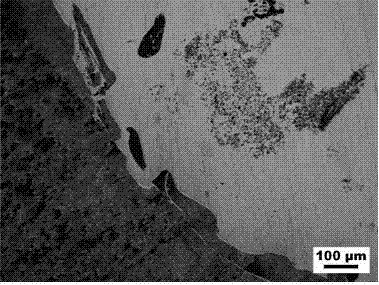

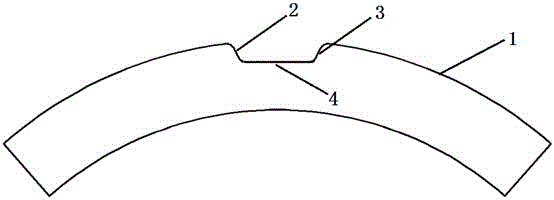

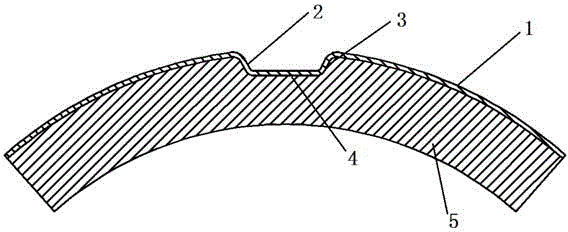

Submerged-arc welding straight welded pipe diameter expansion outer fan-shaped block for deep sea and surface protection method thereof

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

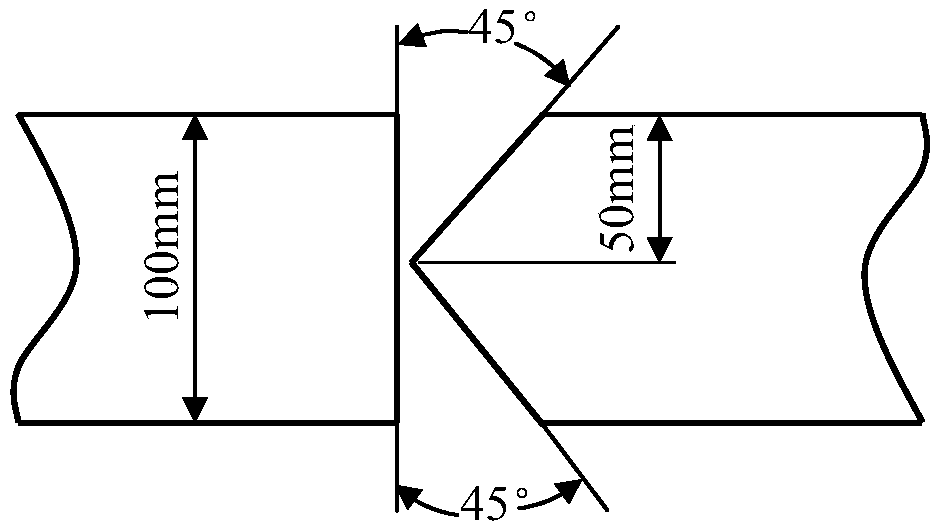

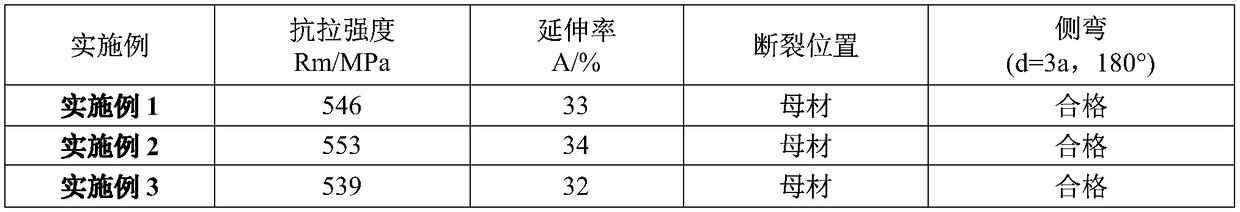

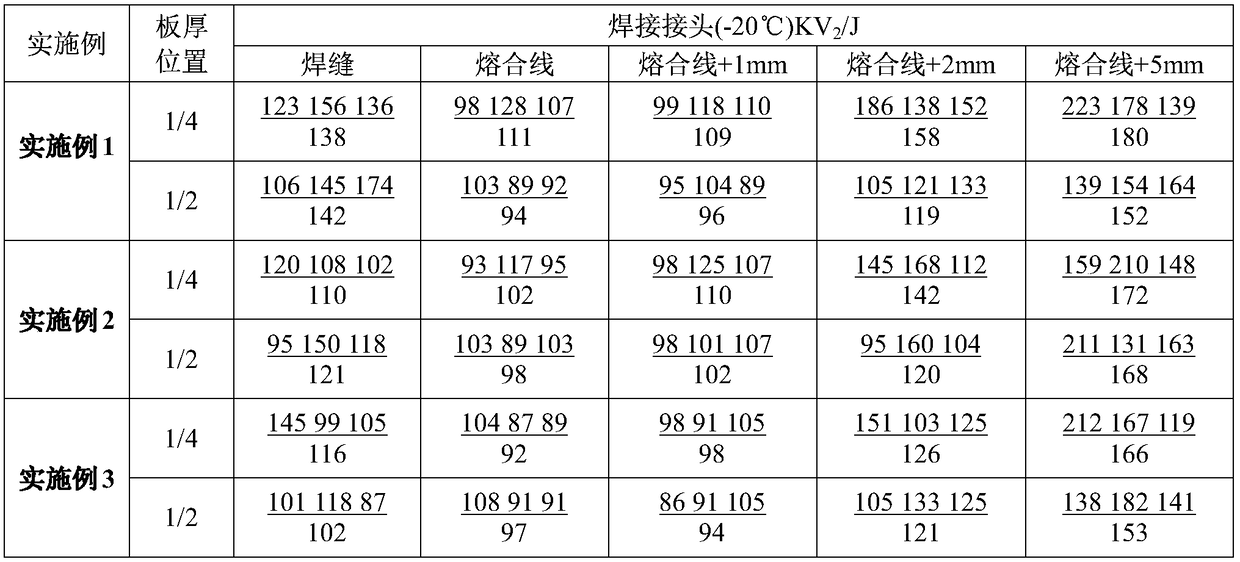

Submerged arc welding method for BB503 steel plate welded joint of 100mm thick blast furnace shell

InactiveCN109352145AArc welding apparatusWelding/soldering/cutting articlesSteel platesSubmerged arc welding

Owner:NANJING IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap