Preparation method for pseudo-boehmite

A technique of pseudo-boehmite and sodium aluminate, applied in the field of preparation of pseudo-boehmite, can solve the problems of prolonging the production cycle, the effect is not obvious, prolonging the pressing and blowing time, etc., and achieves low cost and obvious precipitation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The seed separation mother liquor and the seed separation washing liquid used in the preparation method of the pseudo-boehmite of the present invention are all obtained in the production process of Bayer process alumina.

[0019] Na 2 o T Equal to 100g / L, Al 2 o 3 Equivalent to 40g / L seed fraction mother liquor, Na 2 o T Equal to 20g / L and Al 2 o 3 Equal to 1g / L seed washing solution, Na 2 o T More than 100g / L, Al 2 o 3 More than 40g / L seed separation mother liquor, Na 2 o T More than 20g / L and Al 2 o 3 Sub-washes greater than 1 g / L can also be used with the same results.

[0020] Na 2 o T Indicates the total alkali concentration of sodium aluminate solution, calculated as sodium oxide.

[0021] The following examples use Na 2 o T Equal to 100g / L, Al 2 o 3 Equal to 40g / L seed fraction mother liquor; Na 2 o T Equal to 20g / L and Al 2 o 3 The seed washing solution equal to 1g / L is taken as an example to illustrate the preparation method of the pseu...

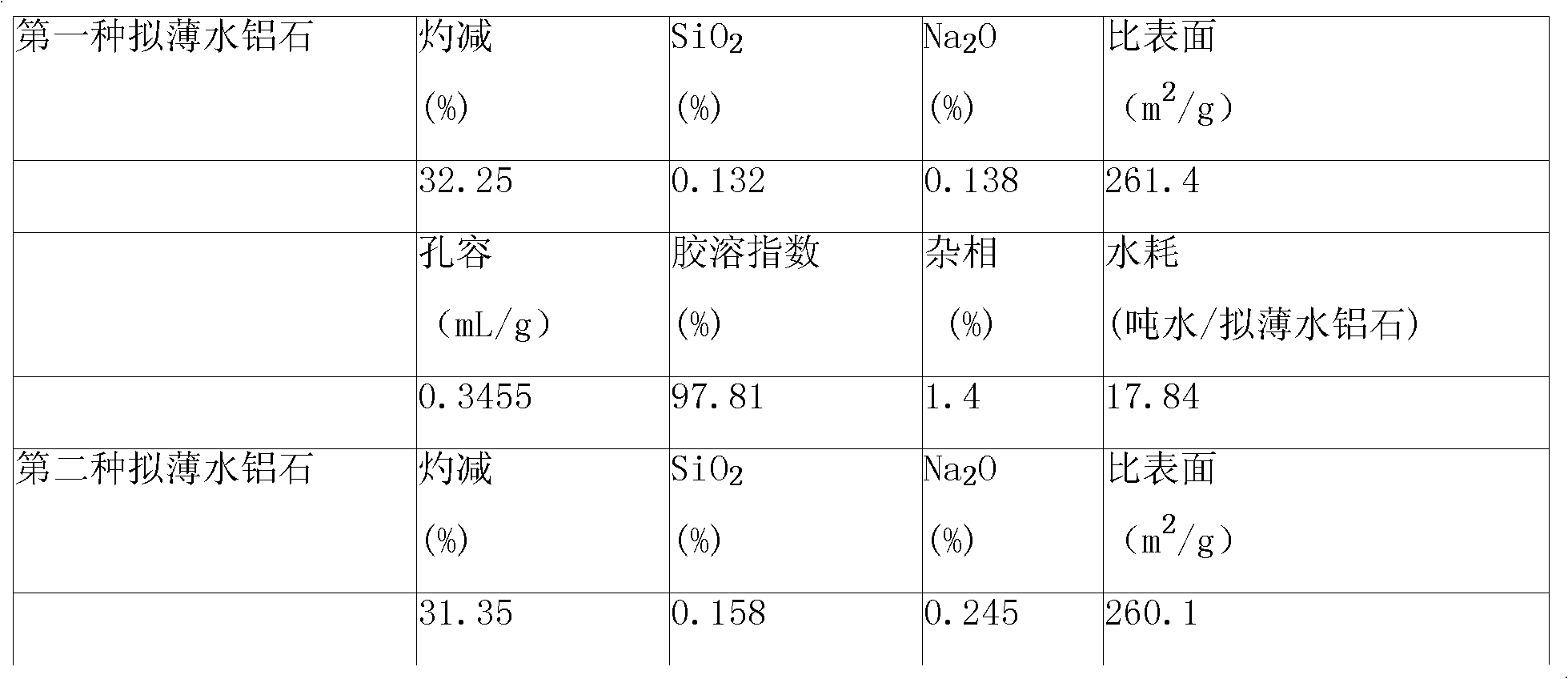

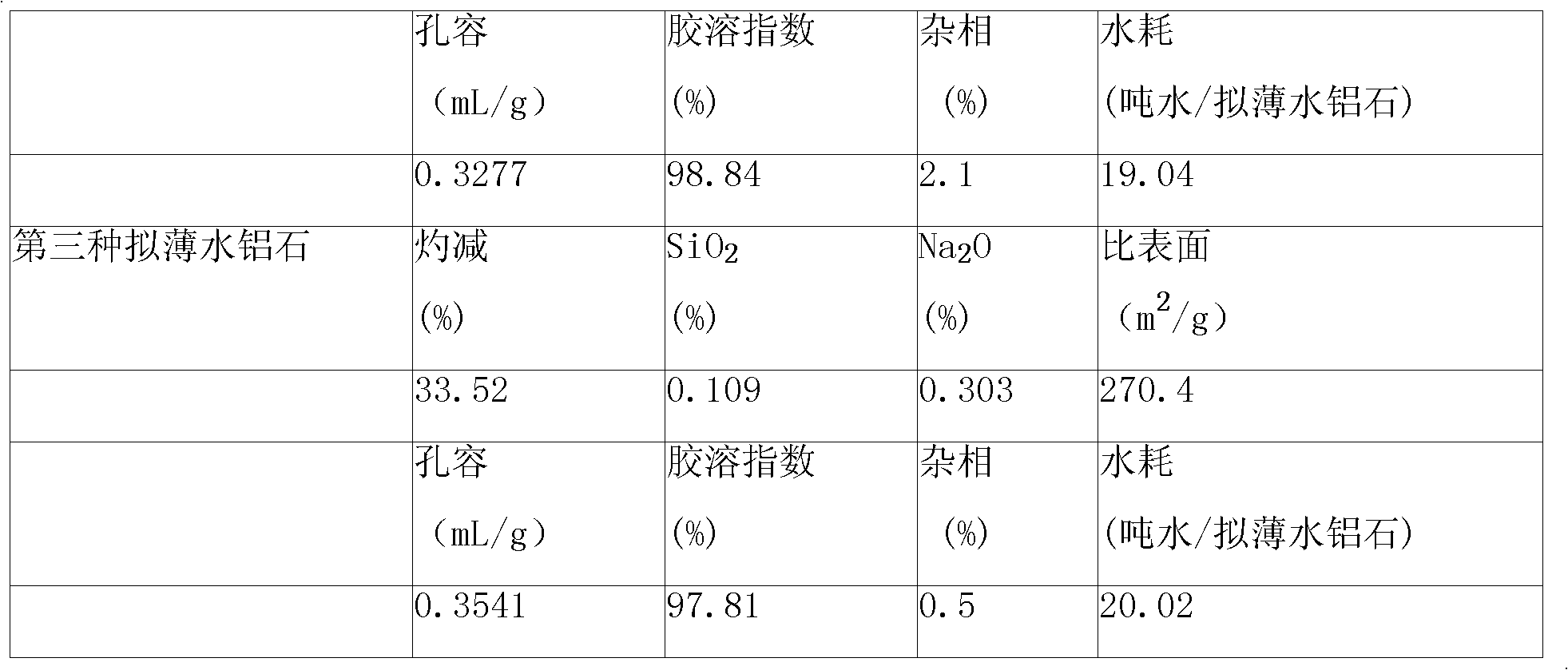

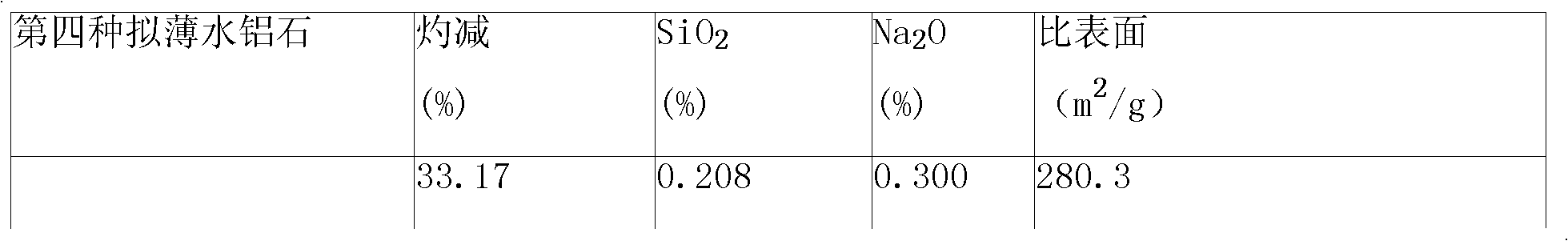

Embodiment 1

[0032] al 2 o 3 The concentration is 105g / L, α ko =1.45 sodium aluminate solution 3L, add distilled water or deionized water to dilute to Al 2 o 3 The concentration is 45g / L, the temperature is cooled to 33-35°C, and the impurities are removed by filtration and purification.

[0033] Into the above-mentioned treated sodium aluminate solution, the concentration of 35-38% CO 2 The gas was rapidly carbonated into a slurry with an aeration time of 12.5 minutes.

[0034] Take the above slurry 40m 3 The steam is directly heated to 85°C, according to the volume of the slurry (m 3 ): the volume of mother liquor (m 3 ) = 1: (0.05-0.6) add the filtered seed separation mother liquor at a temperature of 85° C., and age for 3 hours. Finally, it was separated by filtration, and the filter cake was washed with distilled water at 90°C and then dried in an oven at a temperature of 80°C to obtain pseudo-boehmite.

[0035] In the above method, according to the volume of slurry (m 3 ): th...

Embodiment 2

[0043] al 2 o 3 The concentration is 105g / L, α ko =1.45 sodium aluminate solution 3L, add distilled water or deionized water to dilute to Al 2 o 3 The concentration is 45g / L, the temperature is cooled to 33-35°C, and the impurities are removed by filtration and purification.

[0044] Into the above-mentioned treated sodium aluminate solution, the concentration of 35-38% CO 2 The gas was rapidly carbonated into a slurry with an aeration time of 12.5 minutes.

[0045] Take the above slurry 40m 3 The steam is directly heated to 85°C, according to the volume of the slurry (m 3 ): Volume of washing solution (m 3 ) = 1: (0.1-0.9) add the filtered seed washing solution at a temperature of 85° C., and age for 3 hours.

[0046] Finally, it was separated by filtration, and the filter cake was washed with distilled water at 90°C and then dried in an oven at a temperature of 80°C to obtain pseudo-boehmite.

[0047] In the above method, according to the volume of slurry (m 3 ): V...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap