Method for synchronous mixed cultivation of oil-containing microorganism

A mixed culture and microbial technology, applied in the biological field, can solve the problems of slow accumulation of microbial cells, high cost, and low oil content, and achieve the effects of reducing production costs, increasing accumulation content, and efficient growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

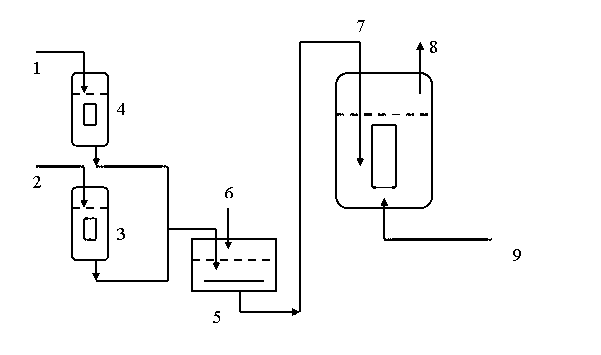

[0030] Example 1

[0031] Rhodotorula glutinis and Chlorella vulgaris were separately cultured in shake flasks using their respective culture media, and after 2 days of culture, seed solutions with OD values of 5 and 10 were obtained. Add the cultured Rhodotorula glutinosa seed liquid, chlorella seed liquid and mixed medium to the mixing tank for mixing. The volume ratio of the Rhodotorula glutinosa seed liquid to the chlorella seed liquid is 1:1, and the seed liquid and mixed culture The volume ratio of the base is 1:5, and the pH of the mixture is adjusted to 7.0. Inoculate the above-mentioned mixed solution into a 10L photobioreactor according to the filling amount of 8L. The reactor is an air-lift stirring type, which can realize the back-mixing of the culture solution. The reactor is a vitreous body. The fluorescent light source is set and the light switch is automatically controlled. Time, the conversion of light to dark during the formation of chlorella culture. The cultu

Example Embodiment

[0032] Example 2

[0033] As described in Example 1, Rhodotorula glutinis and Chlorella vulgaris were separately cultured in shake flasks using their respective culture media. After 2 days of culture, seed solutions with OD values of 15 and 2 were obtained. Add the cultured Rhodotorula glutinosa seed liquid, chlorella seed liquid and mixed medium to the mixing tank for mixing. The volume ratio of the Rhodotorula glutinosa seed liquid to the chlorella seed liquid is 1:5, and the seed liquid and mixed culture The volume ratio of the base is 1:10, and the pH of the mixture is adjusted to 6.5. Inoculate the above-mentioned mixed solution into a 10L photobioreactor according to the filling amount of 8L. The reactor is an air-lift stirring type, which can realize the back-mixing of the culture solution. The reactor is a vitreous body. The fluorescent light source is set and the light switch is automatically controlled. Time, the conversion of light to dark during the formation of chlor

Example Embodiment

[0034] Example 3

[0035] As described in Example 1, Rhodotorula glutinis and Chlorella vulgaris were separately cultured in shake flasks using their respective culture media. After 2 days of culture, seed solutions with OD values of 10 and 6, respectively, were obtained. Add the cultivated Rhodotorula glutinis seed liquid, chlorella seed liquid and mixed medium to the mixing tank for mixing. The volume ratio of the Rhodotorula glutinosa seed liquid to the chlorella seed liquid is 1:10, and the seed liquid and mixed culture The volume ratio of the base is 1:20, and the pH of the mixture is adjusted to 7.5. Inoculate the above-mentioned mixed solution into a 10L photobioreactor according to the filling amount of 8L. The reactor is an air-lift stirring type, which can realize the back-mixing of the culture solution. The reactor is a vitreous body. The fluorescent light source is set and the light switch is automatically controlled. Time, the conversion of light to dark during the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap