Zero mark formation method applicable to EPI (epitaxy) process

A technology of zero mark and process, which is applied in the field of zero mark formation suitable for epitaxial EPI process, can solve the problems of step height reduction, product reliability reduction, use, etc., and achieve the effect of enhancing step difference and improving optical contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

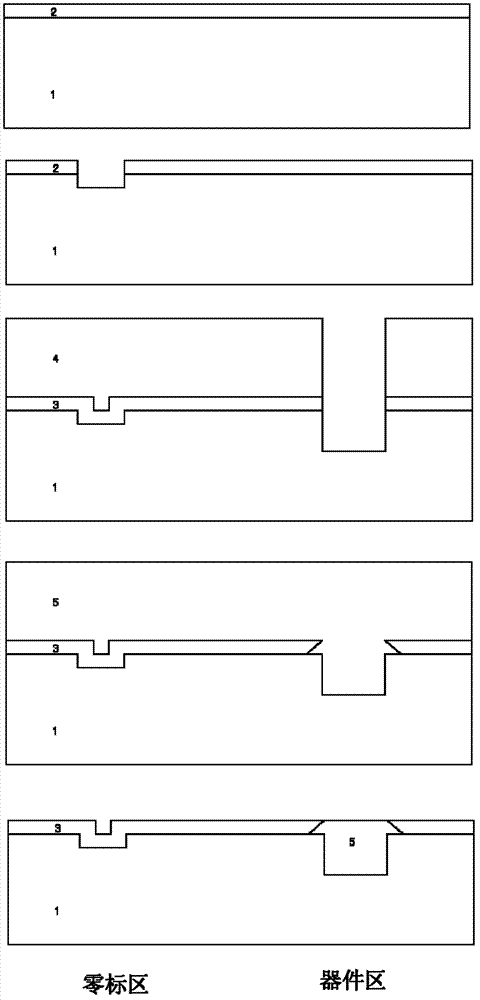

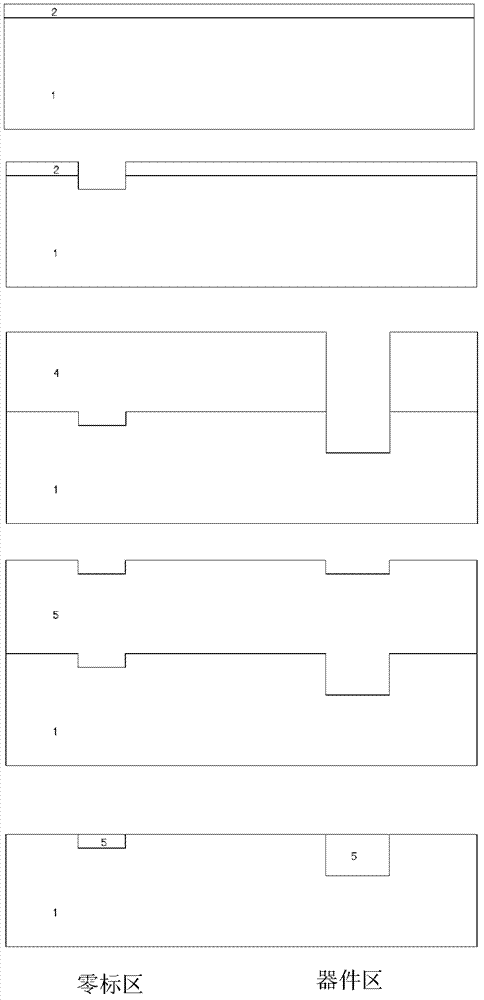

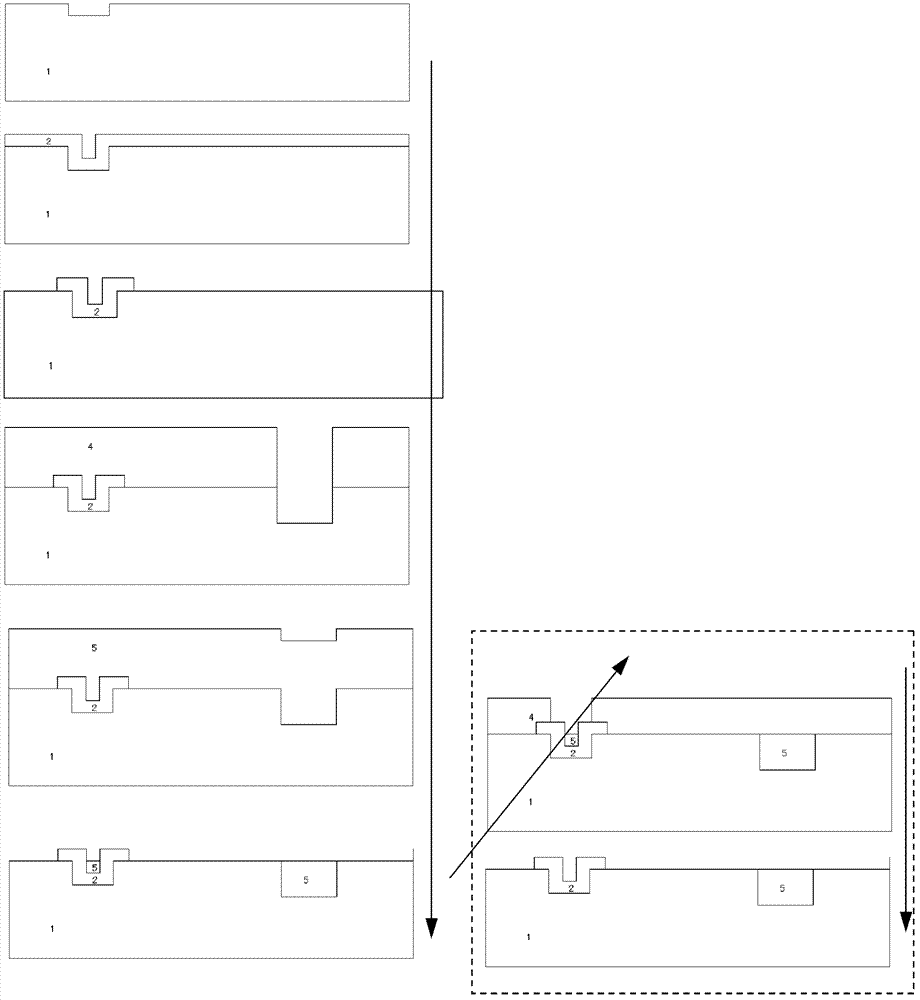

[0024] The invention describes a zero mark forming method suitable for a deep groove etching process without a dielectric barrier layer and a low chemical mechanical grinding CMP polishing amount. Due to the cancellation of the dielectric barrier layer, the zero mark has no epitaxial EPI barrier layer at this time, so the zero mark and the epitaxial EPI grow into one, and the steps are eliminated in the subsequent chemical mechanical polishing CMP, making it unusable. Therefore, it is necessary to use other processes to generate the barrier layer before the epitaxial EPI growth.

[0025] In this process, by changing the process sequence of generating the zero mark, the zero mark is protected by the pad oxide layer, and the pad oxide layer is used as a barrier layer to separate the epitaxial EPI from the zero mark. Enhance the step difference of the zero mark and improve the optical contrast.

[0026] like figure 2 Shown, the present invention comprises the following steps:

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap