Preparation method of freeze-dried egg yolk antibody

An egg yolk antibody and freeze-drying technology, which is applied in the field of preparation of freeze-dried egg yolk antibody, can solve the problems of sharp drop in ultrafiltration membrane water permeability, low product specification content, and few freeze-drying bottles, and achieve freeze-drying time and energy consumption Decline, high antibody concentration factor, high concentration factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

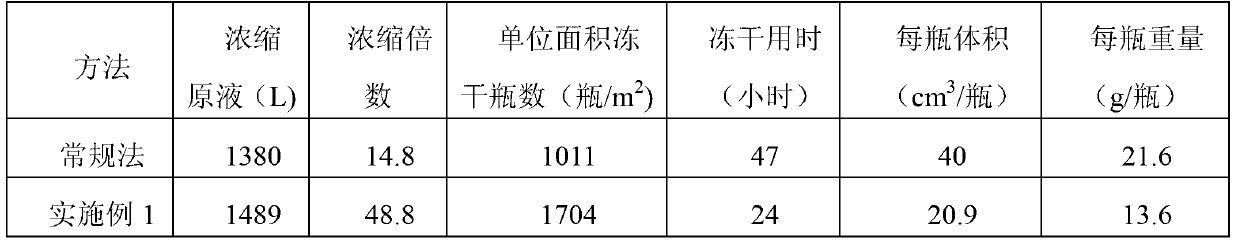

Embodiment 1

[0039] 1.1 Method:

[0040] 1. Concentration:

[0041] (1) Take 1500L of refined goose plague egg yolk antibody, weigh polyaluminium chloride according to the mass volume ratio of polyaluminum chloride and refined goose plague egg yolk antibody 1:1, that is, 1.5kg, dissolve it with 3000mL normal saline and add it , you can stir while adding. At this time, the refined gosling plague egg yolk antibody solution turns from clear and transparent to turbid. After standing for 15 minutes, use a plate and frame filter to add a filter plate for coarse filtration, and the filtrate is filtered with a plate and frame filter. plate and a filter membrane with a filtration precision of 0.45 μm for fine filtration, and the fine filtrate is filtered and sterilized with a microporous filter element filter with a filtration precision of 0.22 μm, and then the primary filtrate is obtained;

[0042] (2) Concentrate the primary filtrate obtained in step (1) by using a hollow fiber ultrafilter to obtai

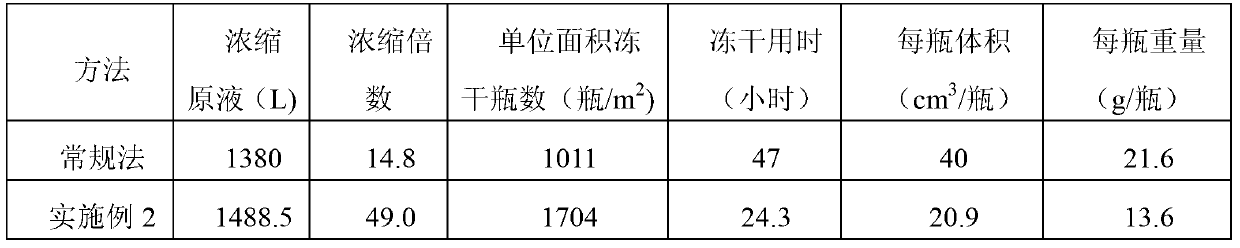

Embodiment 2

[0053] 2.1 Method:

[0054] 1. Concentration:

[0055] (1) Take 1500L of refined goose plague egg yolk antibody, weigh polyaluminum chloride according to the mass volume ratio of polyaluminum chloride and refined goose plague egg yolk antibody 1:1.3, that is, 1.15kg, dissolve it in 2500mL of normal saline and add it , you can stir while adding. At this time, the refined gosling plague egg yolk antibody solution turns from clear and transparent to turbid. After standing for 15 minutes, use a plate and frame filter to add a filter plate for coarse filtration, and the filtrate is filtered with a plate and frame filter. plate and a 0.45 μm filter membrane, and the fine filtrate is filtered and sterilized by a microporous filter element filter with a filtration accuracy of 0.22 μm, and then the primary filtrate is obtained;

[0056] (2) Concentrate the primary filtrate obtained in step (1) by using a hollow fiber ultrafilter to obtain the final concentrate:

[0057] The hollow fiber

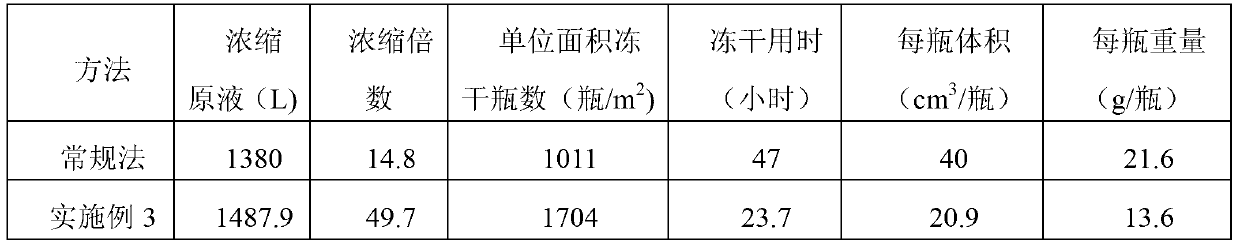

Embodiment 3

[0068] 3.1 Method:

[0069] 1. Concentration:

[0070] (1) Take 1500L of refined goose plague egg yolk antibody, weigh polyacrylamide according to the mass volume ratio of polyacrylamide and refined goose plague egg yolk antibody 1:0.8, that is, 1.88kg, dissolve it with 3000mL normal saline and add it, you can Stir while adding. At this time, the refined gosling plague egg yolk antibody solution changes from clear and transparent to turbid. After standing for 15 minutes, use a plate and frame filter to add a filter plate for coarse filtration, and the filtrate is to use a plate and frame filter to add a filter plate and 0.45μm filter membrane fine filtration, the fine filtrate is filtered and sterilized by a microporous filter element filter with a filtration accuracy of 0.22μm, and then the primary filtrate is obtained;

[0071] (2) Concentrate the primary filtrate obtained in step (1) by using a hollow fiber ultrafilter to obtain the final concentrate:

[0072] Sterilize the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap