Wafer array cathode

A cathode and array technology, applied in the field of microwave sources, can solve problems such as inability to plant, immature flocking technology, poor high temperature ablation resistance, etc., to prolong working life, improve high temperature ablation resistance, and ensure technical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

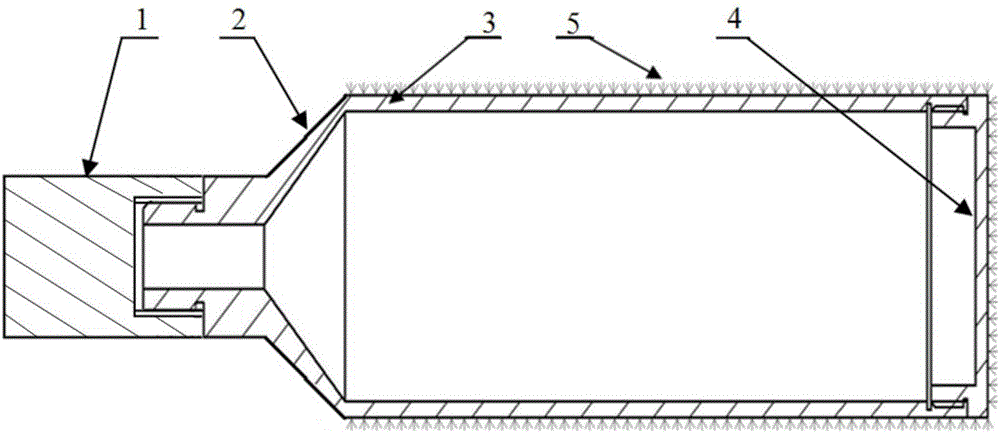

[0017] Figure 4 It is a cross-sectional view of the wafer array cathode of the present invention along the central axis, and the cathode is symmetrical around the axis. The wafer array cathode of the present invention is composed of a cathode seat 1, a tapered section 2, a cathode base 3, a stainless steel ring sheet 4, a dielectric ring sheet 5, and a cathode cap 6. The medium ring sheet 5 is made of carbon fiber cloth or glass fiber cloth, or other materials with low emission threshold and high temperature ablation resistance, and the other parts are made of stainless steel materials.

[0018] The relationship between its structure and assembly is as follows:

[0019] For the convenience of description, it is stipulated below that the end where the cathode holder 1 is located is the left end, and the end where the cathode cap 6 is located is the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap