Intelligent ink supply system of printer

A printer and intelligent technology, applied in printing and other directions, can solve the problems of complicated manufacturing process, high cost and assembly cost, and high assembly cost, and achieve the effect of simple structure, convenient processing and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Example 1

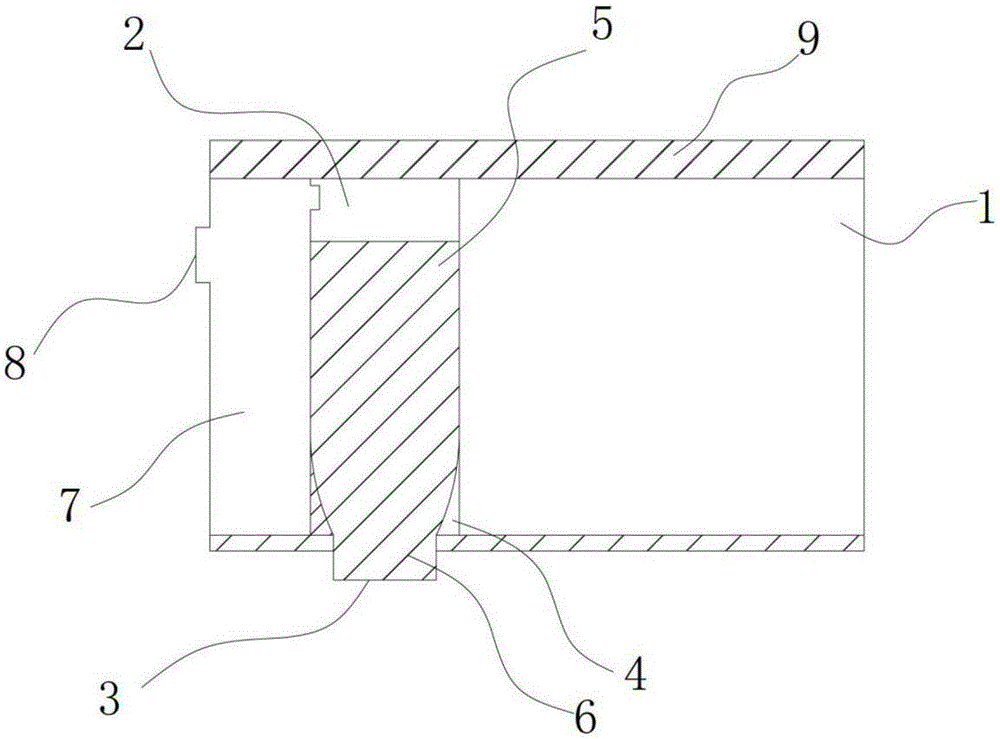

[0018] Such as figure 1 , Figure 1a , Figure 1b As shown, the printer's intelligent ink supply system includes an ink containing cavity 1 and a negative pressure generating component containing cavity 2. The negative pressure generating component containing cavity 2 is provided with an ink outlet 3 at the bottom along the direction of gravity. The ink containing cavity 1 and negative pressure generating The component accommodating cavities 2 communicate with each other through the communicating groove 4;

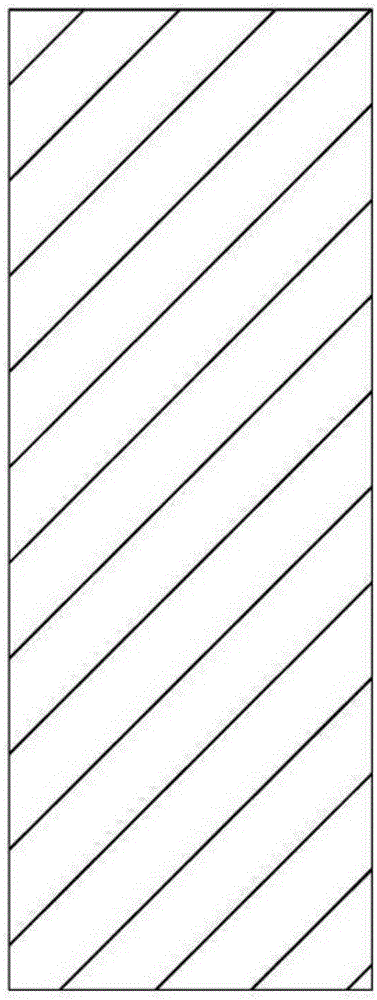

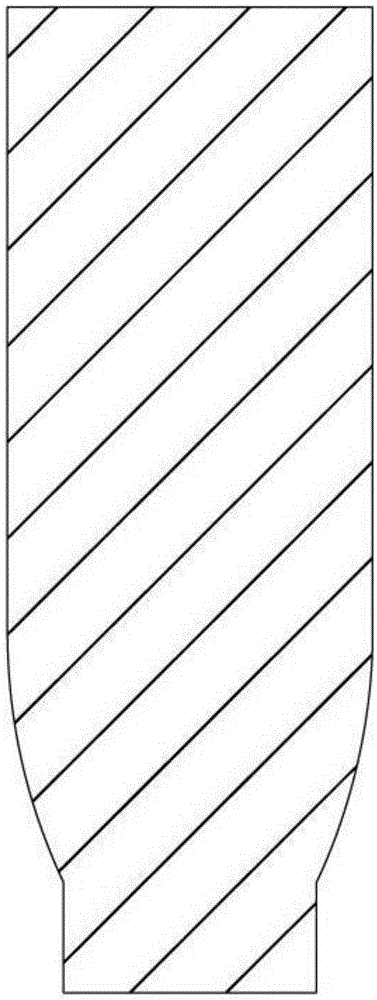

[0019] The ink containing cavity 1 and the negative pressure generating component containing cavity 2 are sealed by a face cover 9; the negative pressure generating component containing cavity 2 is provided with an ink absorbing material 5, and the ink outlet 3 is provided with an ink outlet filter 6;

[0020] As an improvement of the present invention, the ink absorbing material 5 and the ink outlet filter 6 are made of an integrally formed porous material, whi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap