Degradable polylactic acid-polyoxyethylene ordered porous membrane and preparation method thereof

A polyoxyethylene and polylactic acid technology is applied to the polylactic acid porous membrane material and its preparation, and the field of degradable polylactic acid-polyoxyethylene regular porous membrane can solve the problems of complicated operation steps, complicated operation and high cost, and achieve the operation Simple, good compatibility, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Polylactic acid (M W =18×10 4 ) with polyoxyethylene (M W =5×10 4 ) according to the mass ratio of 10:1 in chloroform to prepare a solution with a concentration of 1wt%; then cast the solution on a glass substrate to form a film, and place the glass substrate in an airtight container to form a film at 34 ° C and 80% humidity. After the solvent evaporates, a film is formed on the glass substrate; finally, the film is vacuum-dried at 50°C for 2 hours to remove residual solvent, and the film is placed in a desiccator for later use.

[0018] The surface structure of polylactic acid-polyoxyethylene structured porous membrane was tested by scanning electron microscope (SEM, JEOL-6380LV). The mechanical properties of the composite materials were tested on the universal impact testing machine and electronic tensile machine according to GB1843 for impact and tensile properties.

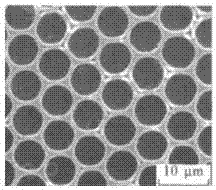

[0019] Such as figure 1 As shown, the membrane in this example is a porous membrane with the same

Embodiment 2

[0021] Polylactic acid (M W =18×10 4 ) with polyoxyethylene (M W =5×10 4 ) according to the mass ratio of 10:1 in dichloromethane to prepare a solution with a concentration of 1wt%; then cast the solution on a glass substrate to form a film, and place the glass substrate in an airtight container at 34°C and 65% humidity to form a film After the solvent evaporates, a film is formed on the glass substrate; finally, the film is vacuum-dried at 50°C for 2 hours to remove residual solvent, and the film is placed in a desiccator for later use.

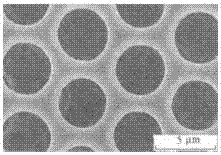

[0022] Test method is identical with the test method of embodiment 1, in conjunction with figure 2 Analysis shows that the membrane prepared in this example is a porous membrane, the size of the pores is the same, and the diameter of the pores is about 4um, which is smaller than that in Example 1, mainly because the humidity is adjusted to 65% when the temperature is constant. The lower the humidity, the smaller the volume of the droplet,

Embodiment 3

[0024] Polylactic acid (M W =1×10 5 ) with polyoxyethylene (M W =5×10 4 ) Prepare a solution with a concentration of 1wt% in tetrahydrofuran according to a mass ratio of 5:1; then cast the solution on a glass substrate to form a film, and place the glass substrate in an airtight container to form a film at 34°C and 75% humidity. After the solvent evaporates, a film is formed on the glass substrate; finally, the film is vacuum-dried at 50°C for 2 hours to remove the residual solvent, and the film is placed in a desiccator for later use.

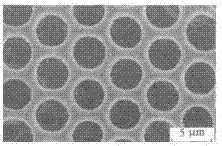

[0025] Test method is identical with the test method of embodiment 1, in conjunction with image 3 According to the analysis, the membrane prepared in this embodiment is a porous membrane, the size of the pores is uniform, and the diameter of the pores is about 4.5um. Compared with Example 1, the pore diameter becomes smaller, mainly because the humidity is adjusted to 75% under the condition of constant temperature, the humidity becomes lowe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap