Gas analyzer and gas analysis method

A gas analyzer and gas detection technology, applied in the direction of material analysis, material analysis through optical means, instruments, etc., can solve the problems that are not conducive to the miniaturization of instruments, inaccurate measurement, expensive cost, etc., to overcome moisture interference, measure accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

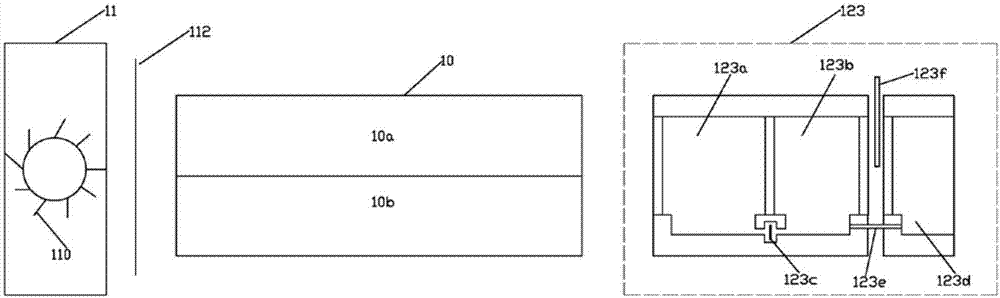

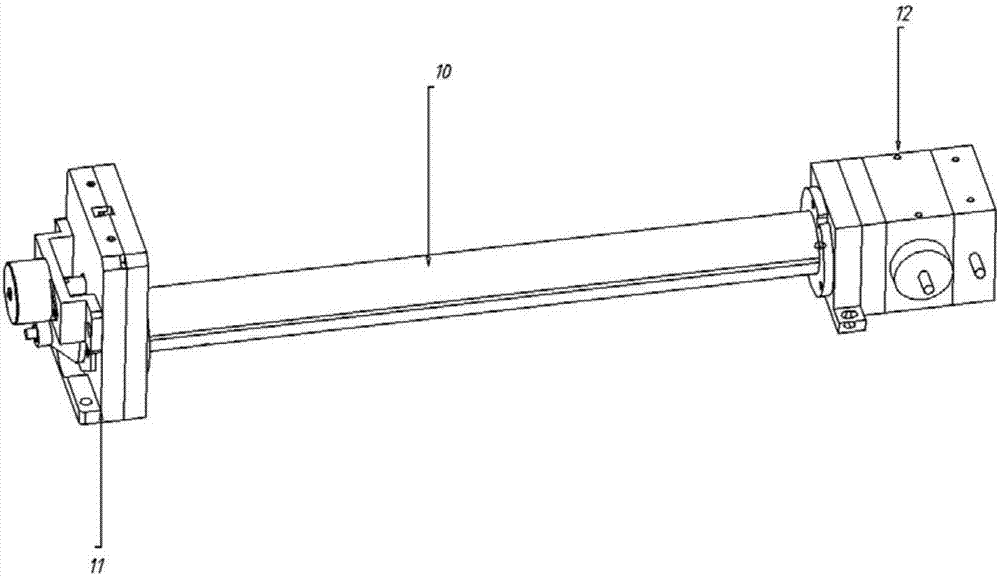

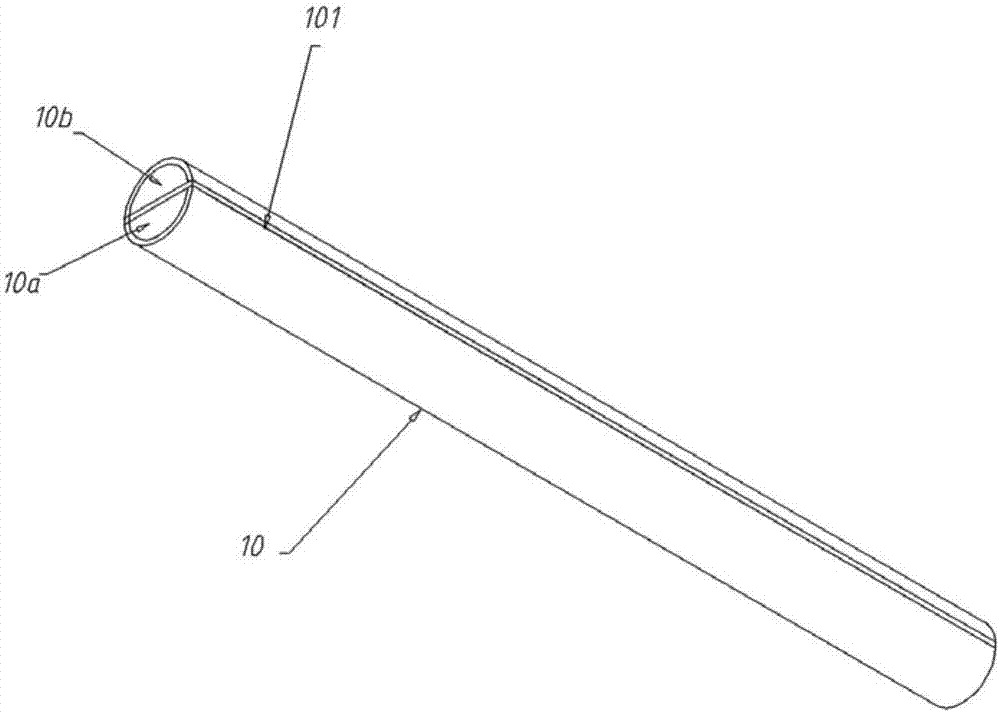

[0048] reference figure 1 —5. A gas analyzer, including a cavity 10, a light source module 11, a light receiving module 12, and a processing unit 13. One end of the cavity 10 is connected to the light source module 11, and the other end is connected to the light receiving module 12 through The partition 101 arranged at the central axis of the cavity 10 divides the cavity 10 into two air chambers of the same size and shape, namely the reference air chamber 10a and the measurement air chamber 10b. In this embodiment, the reference air chamber 10a The measuring gas chamber 10b is symmetrically arranged with respect to the partition 101, and the cross-sections of the reference gas chamber 10a and the measuring gas chamber 10b are both set to be semicircular. It should be considered that in actual applications, rectangular cross-sections or other geometric shapes are within the protection scope of this scheme.

[0049] The partition 101 has the same length as the cavity 10. The partitio

Embodiment 2

[0081] reference Figure 5-8 , A gas analysis method applied to the gas analyzer described in the first embodiment, including the following steps:

[0082] S1: Fill the measuring gas chamber 10b with a measured gas of a known concentration. In this embodiment, the measured gas is SO2 for example;

[0083] S2: Fill the reference gas chamber 10a with N2;

[0084] S3: The light source 110 periodically and alternately irradiates the reference gas cell 10a and the measurement gas cell 10b, the measured gas SO2 of known concentration absorbs the light emitted by the light source 110, and the reference gas N2 does not absorb the light emitted by the light source 110;

[0085] S4: The signals of the reference gas cell 10a and the measuring gas cell 10b are detected by the microfluidic infrared gas detection device 123, and the SO2 absorbed emission from the measuring gas cell 10b is received by the microfluidic infrared gas detection device 123 (for example, SO2 microfluidic infrared sensor) Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap