Device and method for simultaneously separating and recovering multiple heavy metals from electroplating wastewater

A technology for the simultaneous separation of electroplating wastewater, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of long practical time, high cost, and large specific surface area, so as to improve the treatment effect and reduce equipment investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

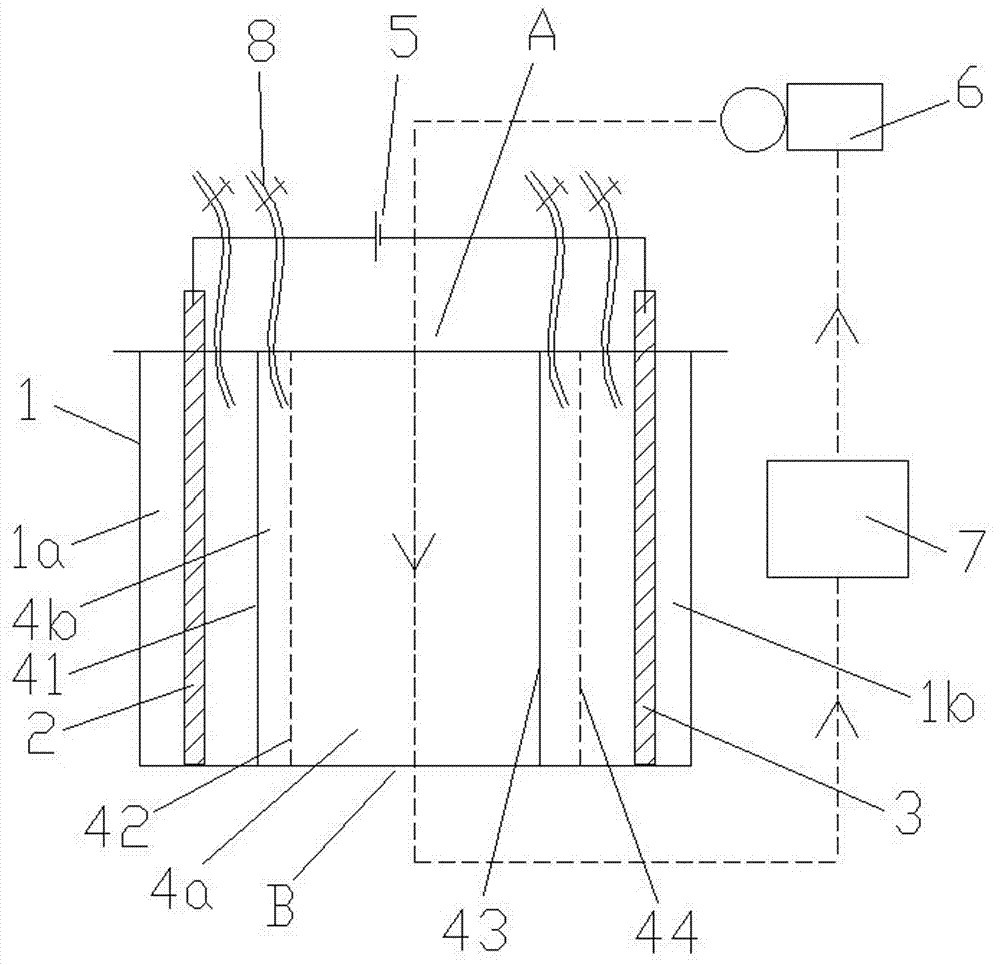

[0024] figure 1 It is a schematic structural diagram of an embodiment of the present invention.

[0025] The reference signs are: electroplating wastewater inlet A, electroplating wastewater outlet B, device frame 1, anode reaction tank 1a, cathode reaction tank 1b, anode plate 2, cathode plate 3, wastewater treatment channel 4a, metal recovery chamber 4b, The first cation exchange membrane 41, the first anion exchange membrane 42, the second cation exchange membrane 43, the second anion exchange membrane 44, the DC power supply 5, the waste water pump 6, the electroplating waste water tank 7, and the outlet pipe 8.

[0026] figure 1 It is a schematic diagram of the structure of the present invention. As shown in the figure, the present invention discloses a device for simultaneous separation and recovery of multiple heavy metals in electroplating

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap