Gas separator in wet process purification production of dissolved acetylene

A gas separator and wet purification technology, which is applied to acetylene generators, parts of acetylene gas generators, separation methods, etc., can solve problems such as low separation efficiency, improve treatment efficiency, ensure treatment effect, and improve treatment efficiency. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0028] In this example

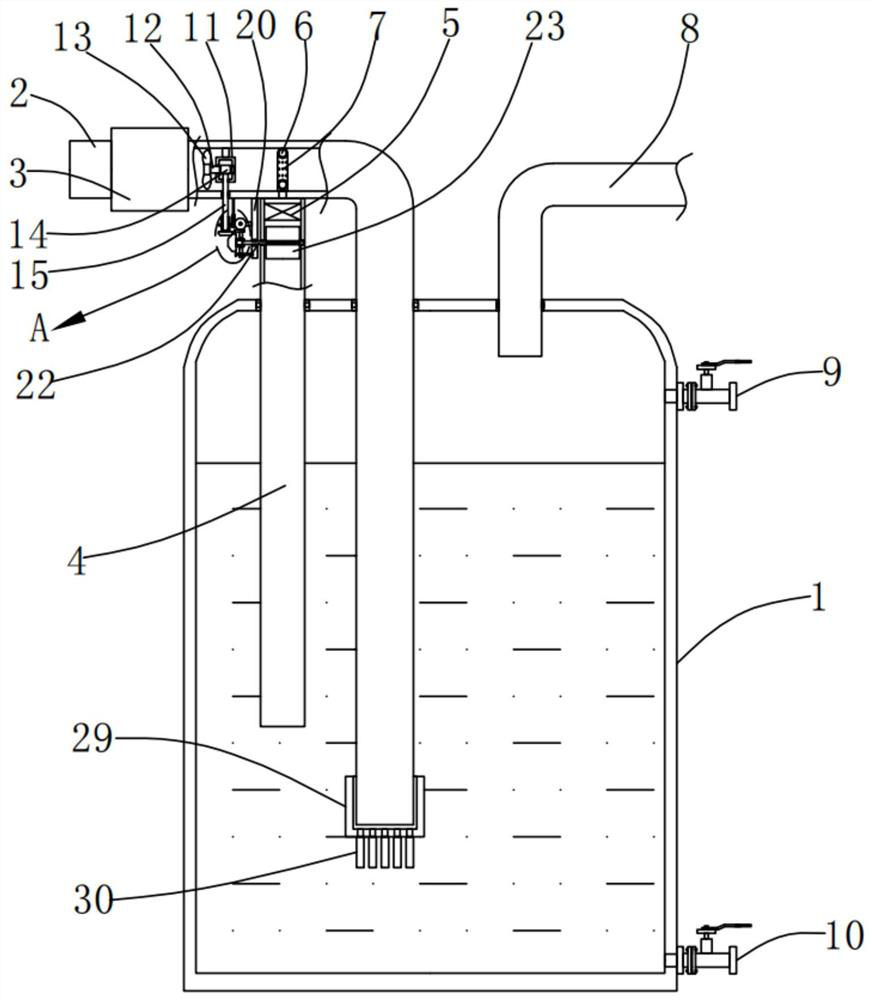

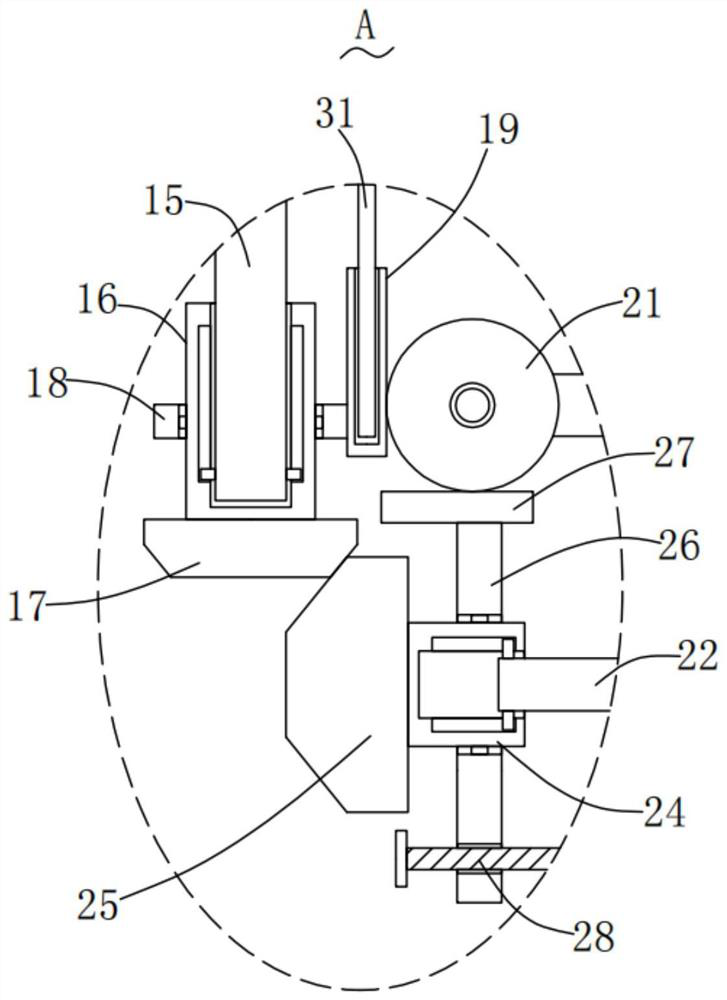

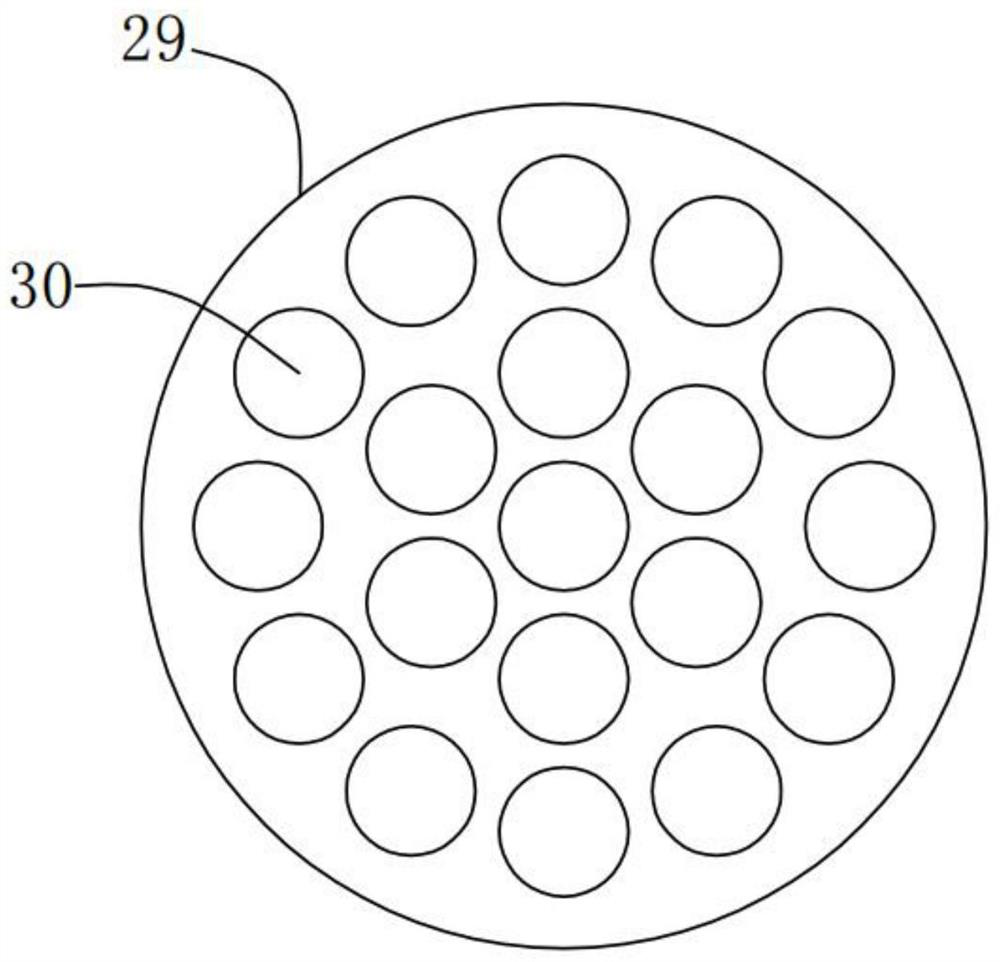

[0029] Please refer to Figure 1-5 The gas separator in the production of dissolved acetylene wet method includes: tank 1; intake pipe 2, the air tube 2 is fixedly mounted on the tank 1, and the bottom end of the intake pipe 2 extends to can body 1; filter 3, the filter 3 is disposed on the intake pipe 2; a liquid absorbent tube 4 is fixedly mounted within the tank 1, and the hydraulic tube 4 The top end extends to the can body 1; the one-way valve 5 is provided in the hydraulic tube 4; the annular tube 6, the annular tube 6 is fixedly mounted in the intake pipe 2, and The annular tube 6 is in communication with the water-absorbent tube 4; a plurality of micropores 7, the plurality of the micropores 7 are symmetrically opened on the inner wall of the annular tube 6; an exhaust pipe 8, the exhaust pipe 8 fixed mounting On the tank 1, the b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap