Preparation method for color film

A color film and base film technology, applied in the field of diamond-like film preparation, can solve the problems of low color film, easy scratching or damage, affecting the lasting aesthetic effect of product appearance, etc., and achieve the effect of rich and changeable colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The present embodiment provides a kind of preparation method of hydrophilic diamond-like carbon film, comprises the following steps:

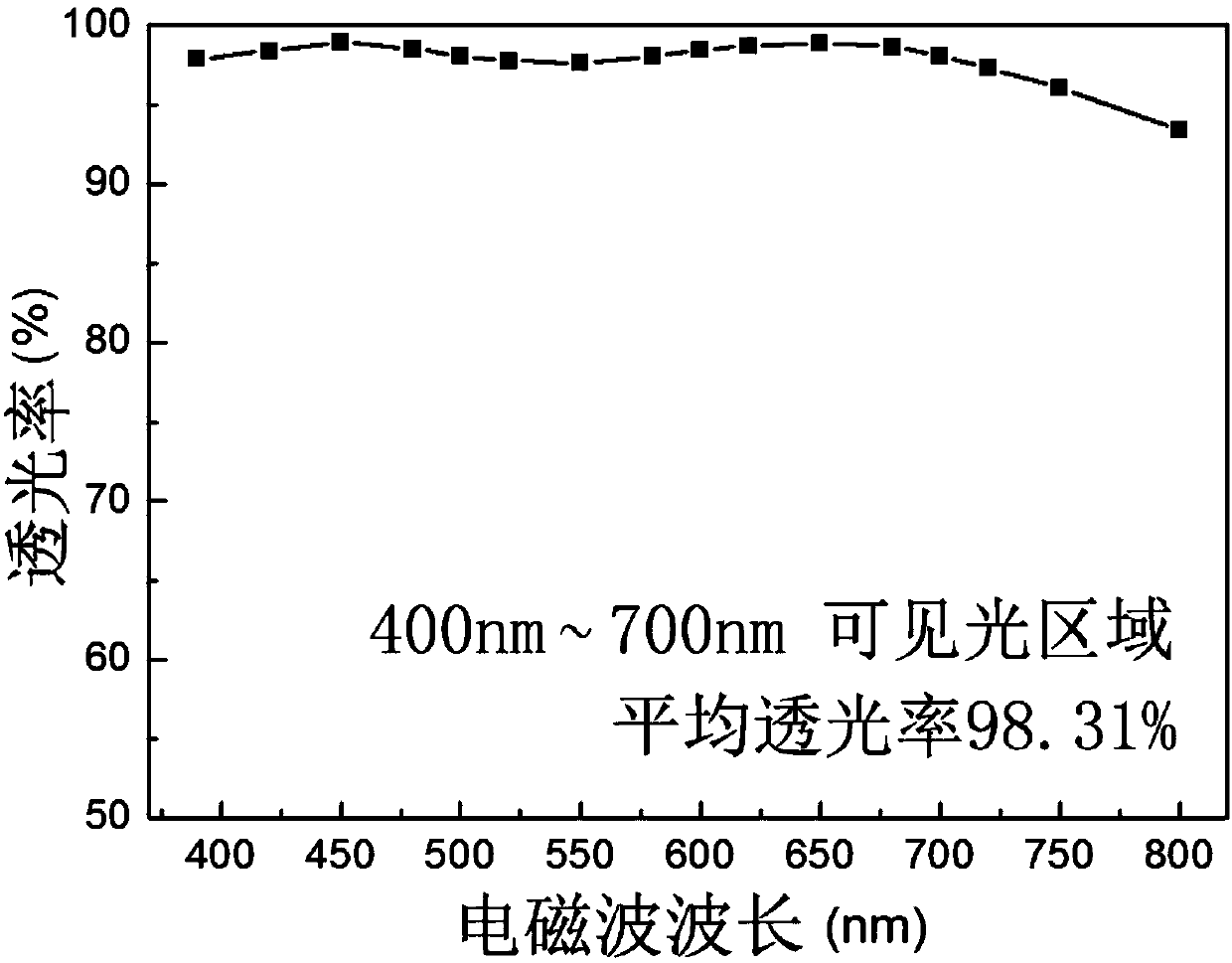

[0020] The prepared aluminum substrate is placed in a reaction chamber, and a mixed gas of methane, hydrogen and oxygen is introduced into the reaction chamber according to a volume flow ratio of 3:100:1. Preferably, in this embodiment, the standard gas flow rates for controlling methane, hydrogen and oxygen are respectively: 12 sccm for methane, 400 sccm for hydrogen, and 4 sccm for oxygen. Further, control the reaction conditions: select a solid microwave source with a microwave frequency of 915MHz, a temperature of 400°C, a microwave power of 1.5kw-2.5kw, and an air pressure of 20-30mbar to form a hydrophilic diamond-like carbon film on the surface of the aluminum substrate. Specifically, the coating speed is preferably 45-60 minutes to deposit 1 μm to form a hydrophilic diamond-like carbon film with a thickness close to 5 μm (maximum th

Embodiment 2

[0023] The present embodiment provides a method for preparing a hydrophobic diamond-like carbon film, comprising the steps of:

[0024] The prepared aluminum substrate is placed in a reaction chamber, and a mixed gas of methane, hydrogen and oxygen is introduced into the reaction chamber according to a volume flow ratio of 3:100:1. Preferably, in this embodiment, the standard gas flow rates for controlling methane, hydrogen and oxygen are respectively: 12 sccm for methane, 400 sccm for hydrogen, and 4 sccm for oxygen. Further, control the reaction conditions: choose a high-power solid microwave source with a microwave frequency of 915MHz, a temperature of 400°C, a power of 3kw-4kw, and an air pressure of 35-45mbar to form a hydrophobic diamond-like carbon film on the surface of the aluminum substrate. Specifically, the coating speed is preferably 45-60 minutes to deposit 1 μm, forming a hydrophobic diamond-like carbon film with a thickness close to 5 μm (the maximum thickness is

Embodiment 3

[0027] This embodiment introduces a color film and its preparation method.

[0028] Such as Figure 4 As shown, the color film 101 of this embodiment includes: an aluminum substrate 102 , a base film 103 , and a protective layer 104 are sequentially arranged from bottom to top. Wherein, the material of the aluminum substrate 102 can be, for example, metal aluminum or aluminum alloy. The base film 103 can be a color coating film with various colors on the market.

[0029] Preferably, the protective layer 104 is made of a hydrophilic or hydrophobic diamond-like carbon film, and its thickness is not greater than 5 μm. In order to improve the adhesion of the diamond-like carbon film to the base film, a bonding layer 105 is also included between the protective layer 104 and the base film 103. In this embodiment, the material of the bonding layer 105 can be, for example, nano-silica-epoxy resin, Silicone resin, the thickness is about 0.5 ~ 2μm.

[0030] The preparation method of th

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap