Material used for making multi-composite bullet-proof vest and performance strengthening method

A multi-component composite and body armor technology, applied in chemical instruments and methods, protective clothing, applications, etc., can solve the problems of consuming ineffective power, affecting combat flexibility of combatants, and small bulletproof area, so as to reduce manufacturing and use costs, Strengthen the effect of green environmental protection and shorten the process line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

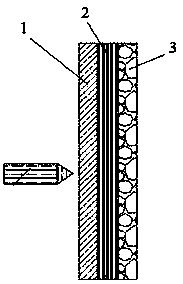

[0018] A material for making multi-element composite body armor, the material includes ultra-thin titanium alloy plate 2, such as figure 1 As shown, the two sides of the ultra-thin titanium alloy plate 2 are respectively provided with a ceramic plate 1 and a composite fiber bulletproof fabric 3, and the ultra-thin titanium alloy plate 2 is a corrugated formed plate.

[0019] A method for enhancing the performance of materials used to make multi-component body armor, such as figure 2 , 3 As shown, the method includes the following steps:

[0020] (1) According to the size of the mold and the size requirements of the bulletproof target material, the ultra-thin titanium alloy plate 2 is blanked. The ultra-thin titanium alloy plate 2 includes Ti-6Al-4V and Ti-5Al-2.5Sn. The thin titanium alloy plate 2 is coated with a mixture of zinc stearate and engine oil with a good ratio to provide lubrication;

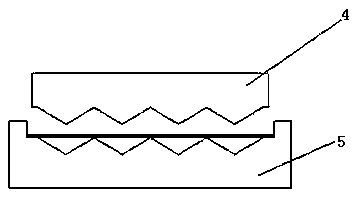

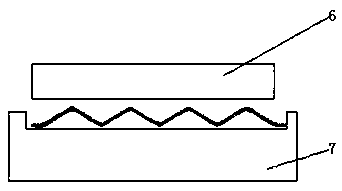

[0021] (2)Using the repeated creasing mold, the ultra-thin titanium alloy plate 2 is press

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap