Coal burning waste gas desulfurization and reutilization device

A waste gas desulfurization and coal-fired technology, applied in the field of desulfurization, can solve the problems that the equipment is easily corroded by acid, the desulfurization gypsum has many impurities, and it is difficult to meet the production demand, and achieves the effect of guaranteed strength, simple structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

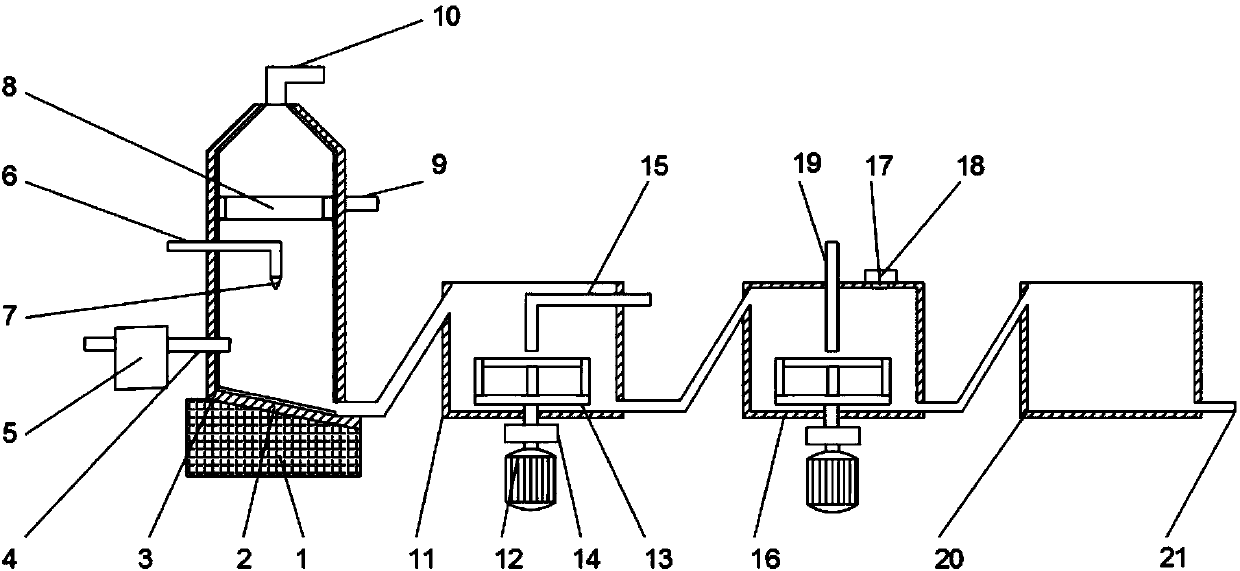

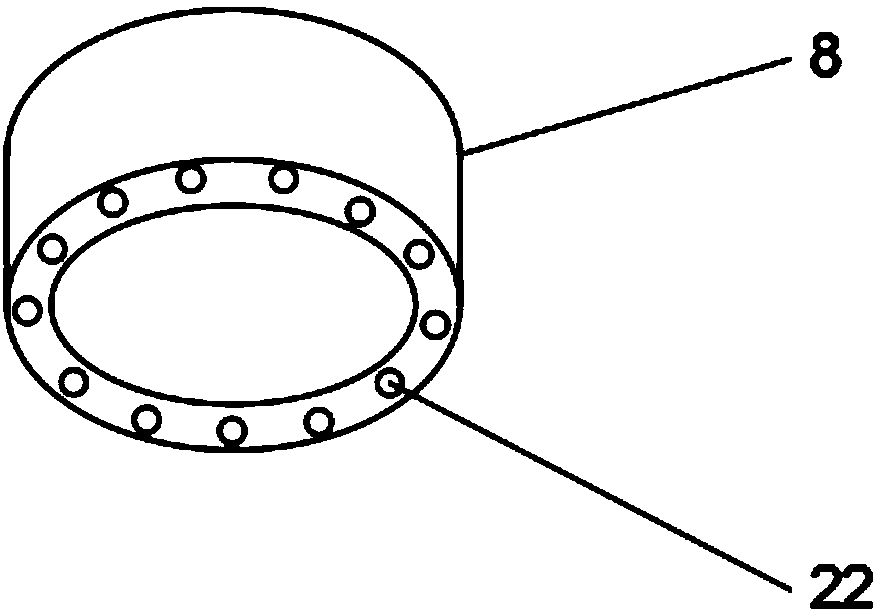

[0017] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a coal-fired waste gas desulfurization reuse device, including a base 1, a desulfurization tower 2, a tempered glass 3, an air intake pipe 4, a filter 5, quicklime slurry water pipe 6, and an atomizing nozzle 7 , annular water pipe 8, water inlet pipe 9, exhaust pipe 10, oxidation pool 11, motor 12, stirring wheel 13, reducer 14, air pipe 15, refining pool 16, ventilation hole 17, valve 18, dilute sulfuric acid pipe 19, sedimentation pool 20, discharge port 21 and through hole 22, a desulfurization tower 2 is built on the top surface of the base 1, tempered glass 3 is fixed on the inner surface of the desulfurization tower 2, and an air inlet pipe 4 is arranged on the side of the lower part of the desulfurization tower 2, and one end of the air inlet pipe 4 is connected to There is a filter 5, and a quicklime slurry water pipe 6 is arranged above the air intake pipe 4, and an atomiz

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap