Cleaning agent for water groove of closestool and preparation method thereof

A cleaning agent and water tank technology, applied in the field of cleaning agents, can solve problems such as piston and gasket failure to seal, threat to human health, corroded skin, etc., to avoid physical damage and environmental damage, with remarkable cleaning effect and moderate decomposition speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

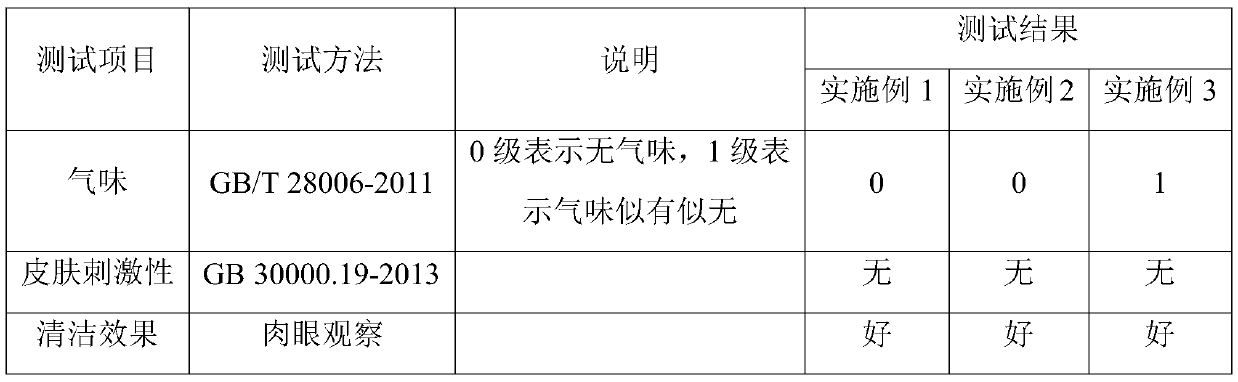

Examples

Embodiment 1

[0027] The toilet sink cleaning agent of the present embodiment is made up of the raw material of following percentage by weight: sodium sulfate 0.125%, sodium metasilicate 0.125%, α-olefin sulfonate 0.15%, surplus is sodium percarbonate, the grain of sodium percarbonate The diameter is 2mm.

[0028] The preparation method of described toilet sink cleaning agent, comprises the following steps:

[0029] (1) commercially available sodium percarbonate is sieved, and it is subsequent use to screen out the sodium percarbonate that diameter is 2mm;

[0030] (2) Mix the sodium percarbonate screened in step (1) with sodium sulfate, sodium metasilicate and α-olefin sulfonate evenly to obtain the product.

[0031] When using the toilet sink cleaning agent of this embodiment, the cleaning agent of this embodiment is added in the toilet sink, the consumption of cleaning agent is 150g, then keep the high liquid level of the sink, and flush after 2 hours.

Embodiment 2

[0033] The difference between this embodiment and Example 1 is that the sodium percarbonate used is the slag in its production process, and the slag with a diameter of more than 2mm is screened out first, and the slag is placed in a hammer with vacuum dust removal and cooling function. In the type pulverizer, hammer and pulverize with the speed of 60r / min, and then screen out the slag with a diameter of 2mm for later use.

[0034] When using the toilet sink cleaning agent of this embodiment, the cleaning agent of this embodiment is added in the toilet sink, the consumption of cleaning agent is 150g, then keep the high liquid level of the sink, and flush after 2 hours.

[0035] The comparison diagram before and after using the toilet sink cleaning agent of this embodiment to clean the toilet sink is shown in figure 1 (The picture on the left is before cleaning, the picture on the right is after cleaning), by figure 1 It can be seen that after cleaning with detergent, the dirt i

Embodiment 3

[0037] The toilet sink cleaning agent of the present embodiment is made up of the raw material of following percentage by weight: sodium sulfate 0.7%, sodium metasilicate 0.7%, dodecyl diphenyl ether disulfonate 0.6%, surplus is sodium percarbonate, The particle size of sodium percarbonate is 5mm.

[0038] Concrete, sodium percarbonate is slag material.

[0039] The difference between the preparation method and Example 2 is that the rotating speed of step (1) is 20r / min.

[0040] When using the toilet sink cleaning agent of the present embodiment, the cleaning agent of the present embodiment is added in the toilet, the consumption of the cleaning agent is 100g, then keep the high liquid level of the water tank, and flush after 2 hours.

[0041] The comparison diagram before and after using the toilet sink cleaning agent of this embodiment to clean the toilet is shown in figure 2 (The picture on the left is before cleaning, the picture on the right is after cleaning), by fi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap