Drawing oil for stamping electronic product plates, and preparation method thereof

A technology of electronic products and stretching oil, which is applied in the petroleum industry, lubricating compositions, etc., to achieve the effects of low odor, no resource loss, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

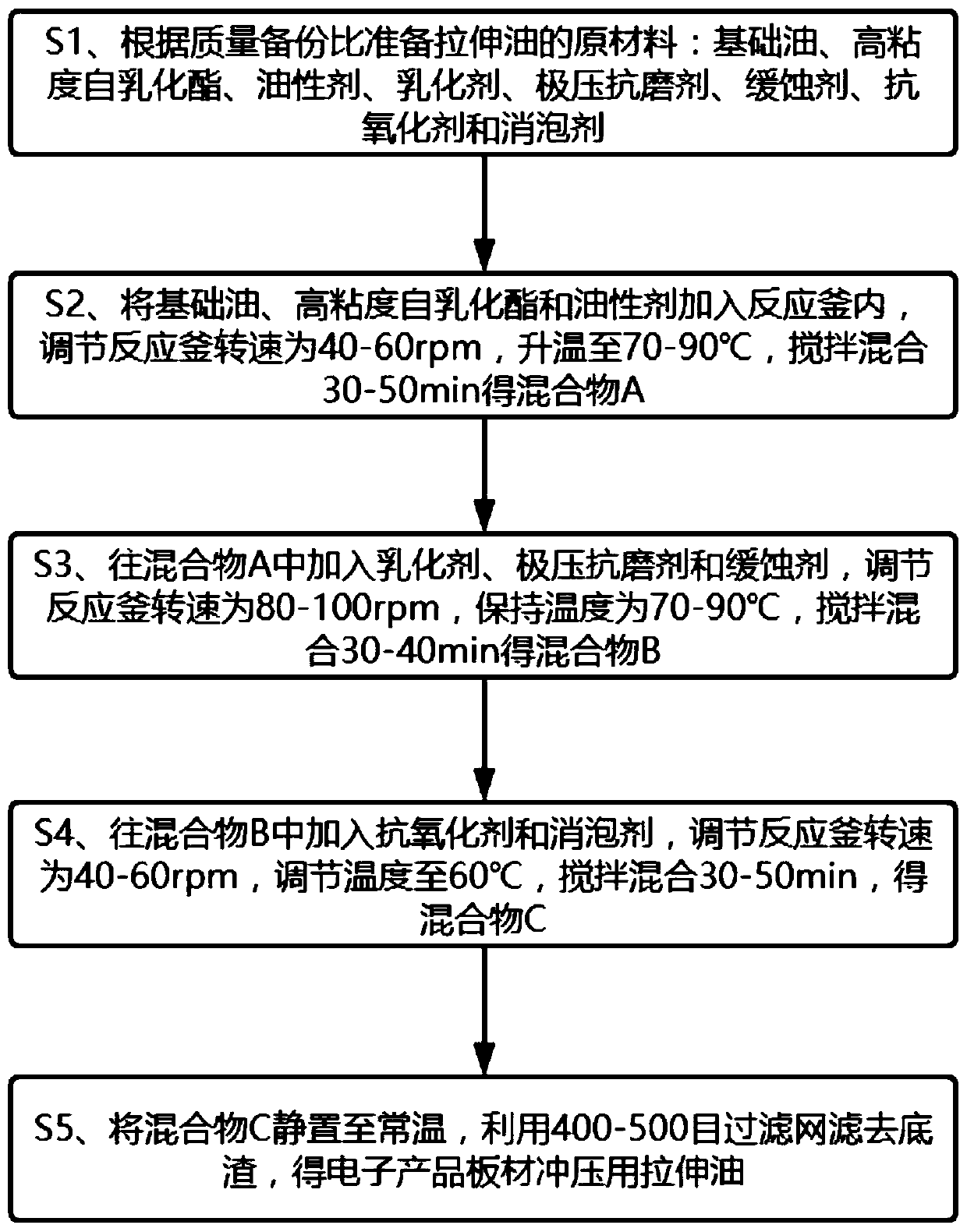

Method used

Image

Examples

Embodiment 1

[0033] A kind of stretching oil for sheet metal stamping of electronic products, comprising the following components by mass percentage:

[0034] Base oil 82.8%, high viscosity self-emulsifying ester 10%, oil agent 3%, emulsifier 3%, extreme pressure antiwear agent 1%, corrosion inhibitor 0.1%, antioxidant 0.05%, defoamer 0.05%.

[0035] Among them, the oily agent is a mixture of sulfurized oil and fatty acid in a mass ratio of 1-2, the sulfurized oil is sulfurized vegetable oil, and the fatty acid is saturated fatty acid; the extreme pressure and antiwear agent is sulfurized lard; the corrosion inhibitor methyl benzotriazole; The emulsifier is polyoxyethylene ether; the antioxidant is N, N'-di-sec-butyl-p-phenylenediamine; the defoamer is polyether modified silicone oil.

[0036] The base oil includes a mixture of vegetable oil, mineral oil and synthetic oil, and the mass ratio of vegetable oil, mineral oil and synthetic oil is 1:1:1, the vegetable oil is soybean oil, the minera

Embodiment 2

[0044] A kind of stretching oil for sheet metal stamping of electronic products, comprising the following components by mass percentage:

[0045] Base oil 74.55%, high viscosity self-emulsifying ester 12.5%, oil agent 6%, emulsifier 4.5%, extreme pressure antiwear agent 2%, corrosion inhibitor 0.3%, antioxidant 0.075%, defoamer 0.075%.

[0046] Among them, the oily agent is a mixture of sulfurized oil and fatty acid at a mass ratio of 1.5:1, the sulfurized oil is sulfurized vegetable oil, and the fatty acid is saturated fatty acid; the extreme pressure antiwear agent is sulfurized cottonseed oil; the corrosion inhibitor is mercaptobenzothiazole; the emulsifier It is polyoxypropylene ether; the antioxidant is N, N'-di-sec-butyl-p-phenylenediamine; the defoamer is polyether modified silicone oil.

[0047]The base oil includes a mixture of vegetable oil, mineral oil and synthetic oil, and the mass ratio of vegetable oil, mineral oil and synthetic oil is 1.5:1.5:1, the vegetable oil

Embodiment 3

[0055] A kind of stretching oil for sheet metal stamping of electronic products, comprising the following components by mass percentage:

[0056] Base oil 66.3%, high viscosity self-emulsifying ester 15%, oil agent 9%, emulsifier 6%, extreme pressure antiwear agent 3%, corrosion inhibitor 0.5%, antioxidant 0.1%, defoamer 0.1%.

[0057] Among them, the oily agent is a mixture of sulfurized oil and fatty acid at a mass ratio of 2:1, the sulfurized oil is sulfurized vegetable oil, and the fatty acid is saturated fatty acid; the extreme pressure antiwear agent is sulfurized olefin cottonseed oil; the corrosion inhibitor is benzotriazole; The emulsifier is a mixture of ethylene oxide and propylene oxide block copolymers; the antioxidant is 2,6-di-tert-butylphenol; the defoamer is polyether modified silicone oil.

[0058] The base oil includes a mixture of vegetable oil, mineral oil and synthetic oil, and the mass ratio of vegetable oil, mineral oil and synthetic oil is 2:2:1, the vege

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap