Sewage treatment system, sewage treatment method and adjustable power supply

A technology of sewage treatment system and sewage treatment method, which is applied in the direction of water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., and can solve the problems of short electrode life, high electrode pickling frequency, and low efficiency. problem, to achieve the effect of prolonging service life, improving efficiency and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

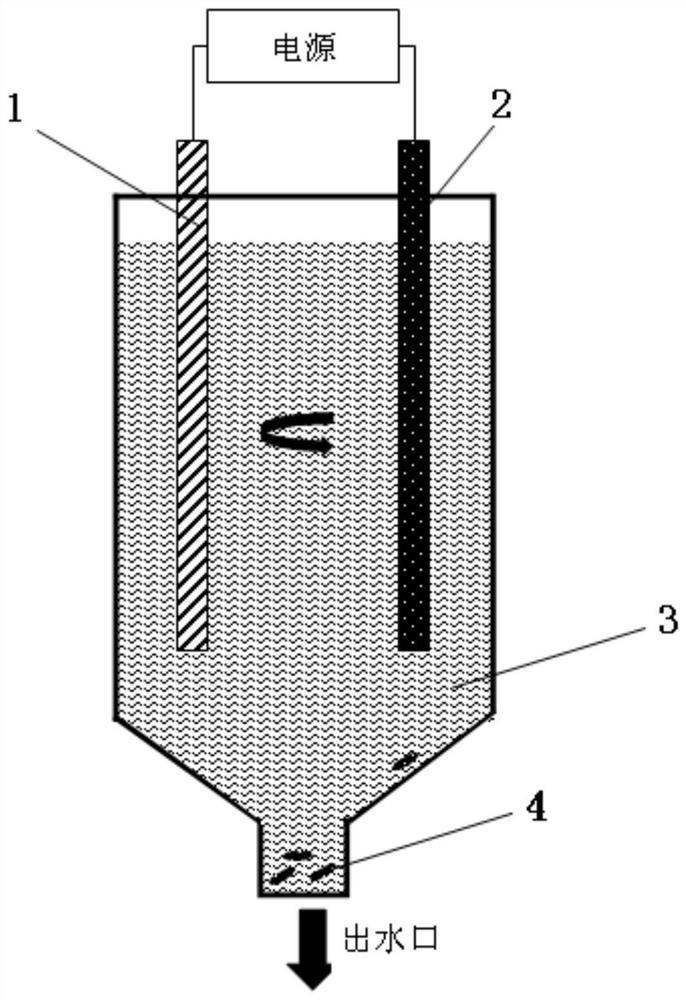

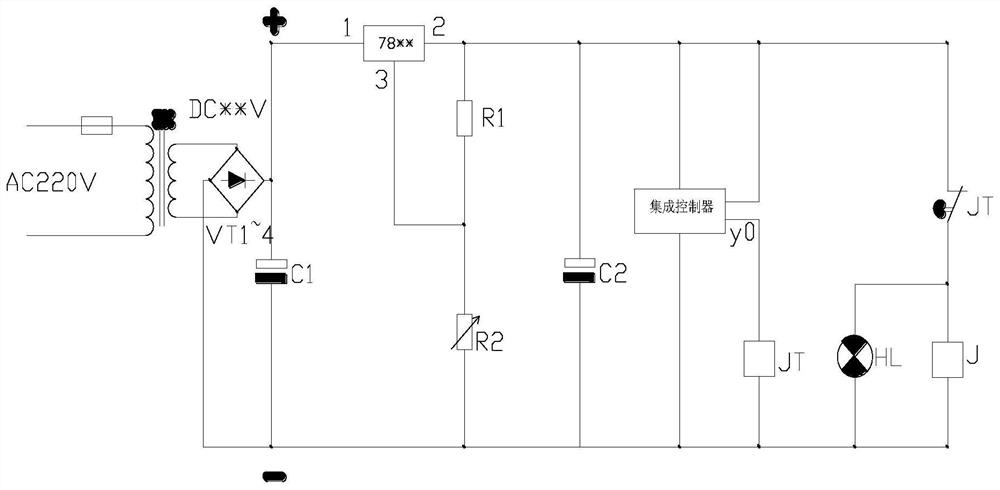

[0039] Specific embodiment one, such as Figure 1 to Figure 3 as shown,

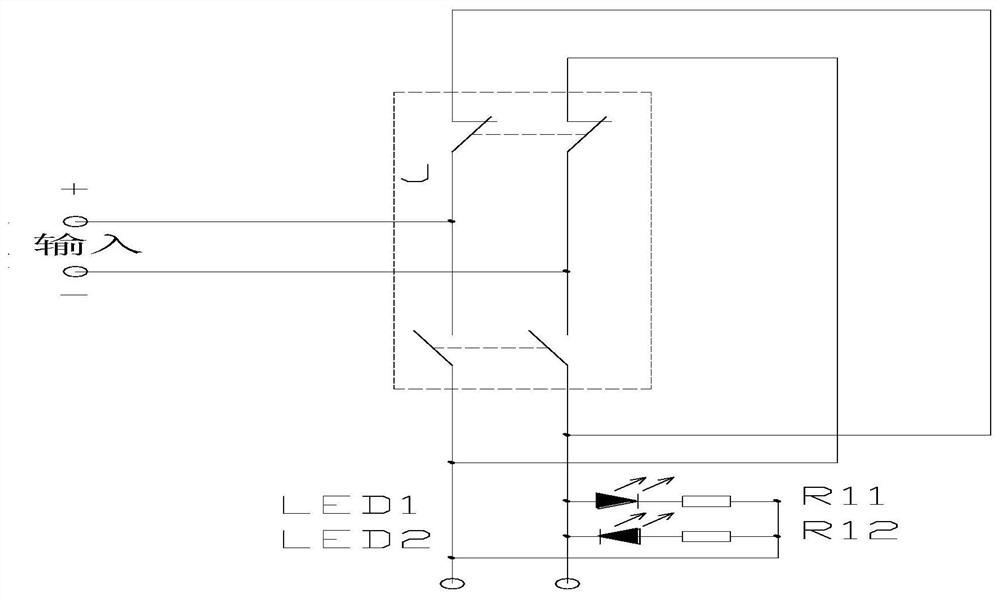

[0040] A sewage treatment system, including a sewage treatment tank, a first electrode 1 and a second electrode 2 arranged in the sewage treatment tank, a stirring system, and a power supply connected to the first electrode 1 and the second electrode 2, in the sewage treatment tank The organic sewage 3 is loaded, and the upper end of the electrode protrudes from the upper surface of the organic sewage 3. The power supply includes a rectifying part, a filtering part, a voltage stabilizing part, an integrated controller, a time control system, and an output relay; after the alternating current passes through the transformer BK, it passes through The rectifier bridge composed of four diodes VT1~VT4, after primary filtering, secondary filtering, voltage stabilization, and then the time relay JT reaches the output terminal, the output terminal has an output relay J, and the polarity of the output terminal of ...

specific Embodiment 2

[0063] Specific embodiment two, such as Figure 4 as shown,

[0064] The process of exchanging the positive and negative poles of the power supply once is regarded as a working cycle. A sewage treatment process includes n working cycles. The system working parameters of all working cycles are obtained in advance according to methods such as experiment, detection, and observation. The working parameters include the positive and negative poles of the power supply. Negative electrode switching time, stirring system stop stirring time, initial current intensity, current decay rate constant, etc., the working parameters are set and stored through the controller of the power supply. In this embodiment, the output current intensity works in a linear decay mode. The specific control process includes the following steps:

[0065] Step 1. Connect the positive and negative poles of the power output terminal to the two electrodes respectively. The positive pole of the power output termin...

specific Embodiment 3

[0071] Specific embodiment three, such as Figure 5 as shown,

[0072] The specific working process of this embodiment is basically the same as that of the third embodiment, except that the current intensity of this embodiment works according to the rule of exponential decrease.

[0073] The stop time of the stirring system is set according to the following rules:

[0074] After the positive and negative poles of the power supply are exchanged, the scaling matter attached to the original cathode electrode begins to fall off, wait for the scaling matter to fall off and sink, and then start the stirring system to start working.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap