Broadband double-layer anti-reflection coating capable of improving efficiency of solar cell and preparation method thereof

A solar cell and broadband technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor anti-reflection effect, and achieve the effects of firm bonding, improved efficiency, and improved preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

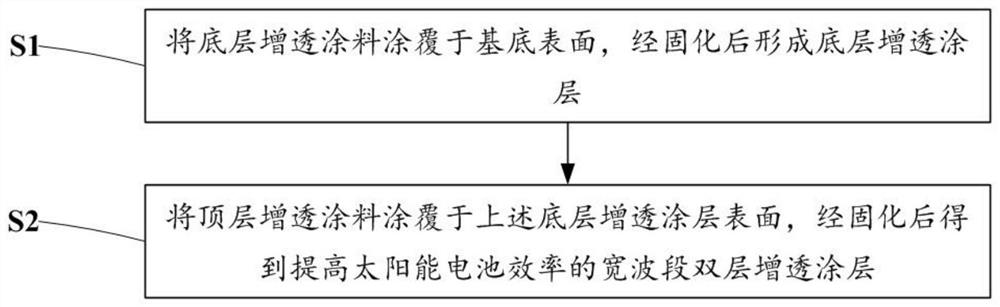

[0025] see figure 1 , the second aspect of the present invention provides a kind of preparation method of the broadband double-layer anti-reflection coating that improves solar cell efficiency, comprises the following steps:

[0026] S1: Apply the bottom anti-reflection coating on the surface of the substrate, and form the bottom anti-reflection coating after curing;

[0027] S2: Coating the top anti-reflection coating on the surface of the bottom anti-reflection coating, and obtaining a broadband double-layer anti-reflection coating for improving the efficiency of solar cells after curing.

[0028] In this embodiment, the curing temperature is 40-60°C, preferably 45-55°C; the curing time is 30-60s, preferably 30-40s.

[0029] In this method, the substrates used are glass, silicon wafers, optical devices and the like.

[0030] The preparation method of the broadband double-layer antireflection coating for improving solar cell efficiency provided by the second aspect of the p...

Embodiment 1

[0033] Synthesis of bottom anti-reflection coating: take 2mL of isopropanol and 50 μL of hydrochloric acid with a molar concentration of 0.1mol / L, then add 200 μL of TEOS, and stir at room temperature for 2 hours to obtain the bottom anti-reflection coating. During this process, the concentration of linear silica polymer in the resulting primer anti-reflection coating was 4.6 wt%.

[0034] Synthesis of the bottom anti-reflection coating: the modified mesoporous silica dispersion and the fluorinated silica polymer solution are mixed in a volume ratio of 2:1 to obtain the bottom anti-reflection coating; wherein,

[0035] The modified mesoporous silica dispersion was obtained by the following steps: 15 g of CTAB solution with a mass concentration of 2.5 wt % and 600 μL of TEA solution with a mass concentration of 10 wt % were added to a 30 mL round bottom flask, magnetically stirred and mixed, while heating in an oil bath to 70°C, add 1.2mLTEOS, stir the reaction at 70°C for 1h, ...

Embodiment 2

[0039] Synthesis of bottom anti-reflection coating: take 2mL of isopropanol and 40 μL of hydrochloric acid with a molar concentration of 0.1mol / L, then add 100 μL of TEOS, and stir at room temperature for 1 hour to obtain the bottom anti-reflection coating. During this process, the concentration of the linear silica polymer in the resulting primer anti-reflection coating was 2.3 wt%.

[0040] Synthesis of the bottom anti-reflection coating: the modified mesoporous silica dispersion and the fluorinated silica polymer solution are mixed in a volume ratio of 4:1 to obtain the bottom anti-reflection coating; wherein,

[0041] The modified mesoporous silica dispersion was obtained by the following steps: 8 g of CTAB solution with a mass concentration of 2.5 wt % and 400 μL of TEA solution with a mass concentration of 10 wt % were added to a 30 mL round-bottomed flask, magnetically stirred and mixed, while heating in an oil bath After reaching 65°C, add 1.2mLTEOS, stir the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap