Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Polymer solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer solutions are solutions containing dissolved polymers. These may be liquid solutions (e.g. in aqueous solution), or solid solutions (e.g. a substance which has been plasticized). The introduction into the polymer of small amounts of a solvent (plasticizer) reduces the temperature of glass transition, the yield temperature, and the viscosity of a melt. An understanding of the thermodynamics of a polymer solution is critical to prediction of its behavior in manufacturing processes — for example, its shrinkage or expansion in injection molding processes, or whether pigments and solvents will mix evenly with a polymer in the manufacture of paints and coatings.

Low Viscosity Liquid Polymeric Delivery System

InactiveUS20090181068A1Heavy metal active ingredientsNervous disorderPolymer sciencePolymer solution

Owner:DUNN RES & CONSULTING

Process for preparing halogen-free atrp products

The present invention relates to the in situ removal of terminal halogen atoms from polymer chains which have been prepared by means of atom transfer radical polymerization, and to the simultaneous removal of transition metals from polymer solutions.

Owner:EVONIK ROEHM GMBH

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

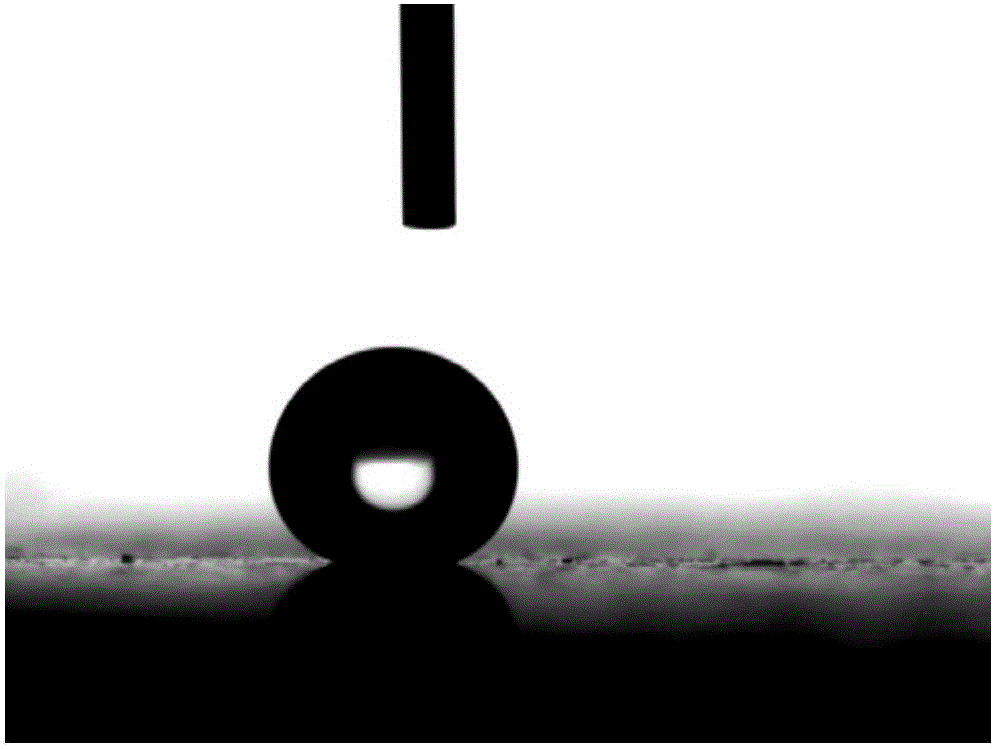

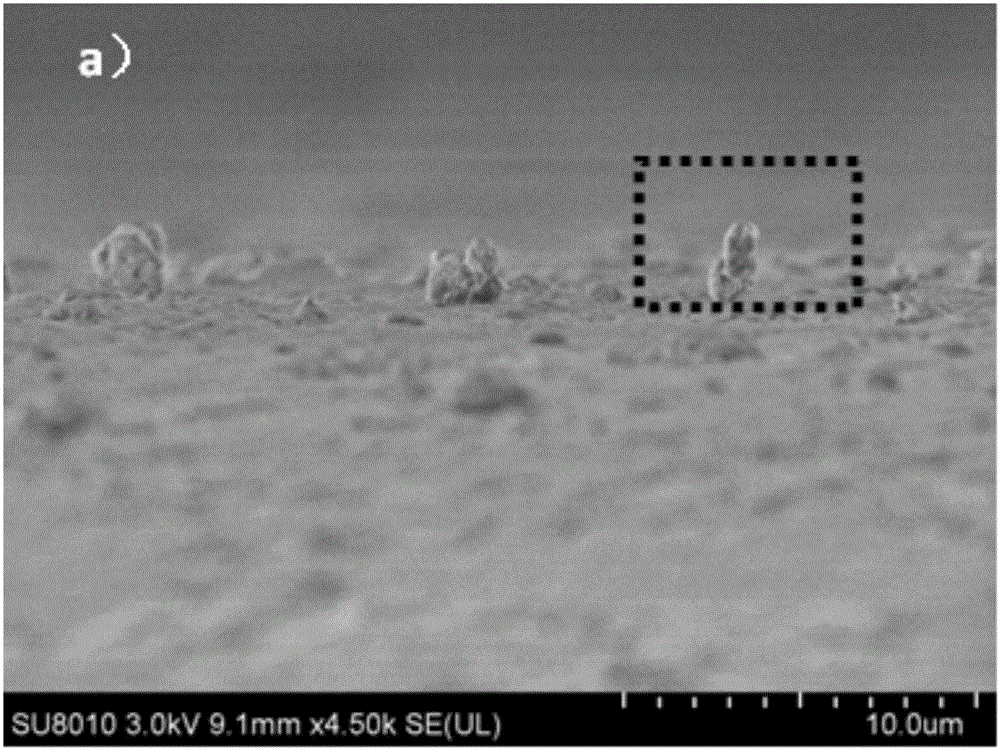

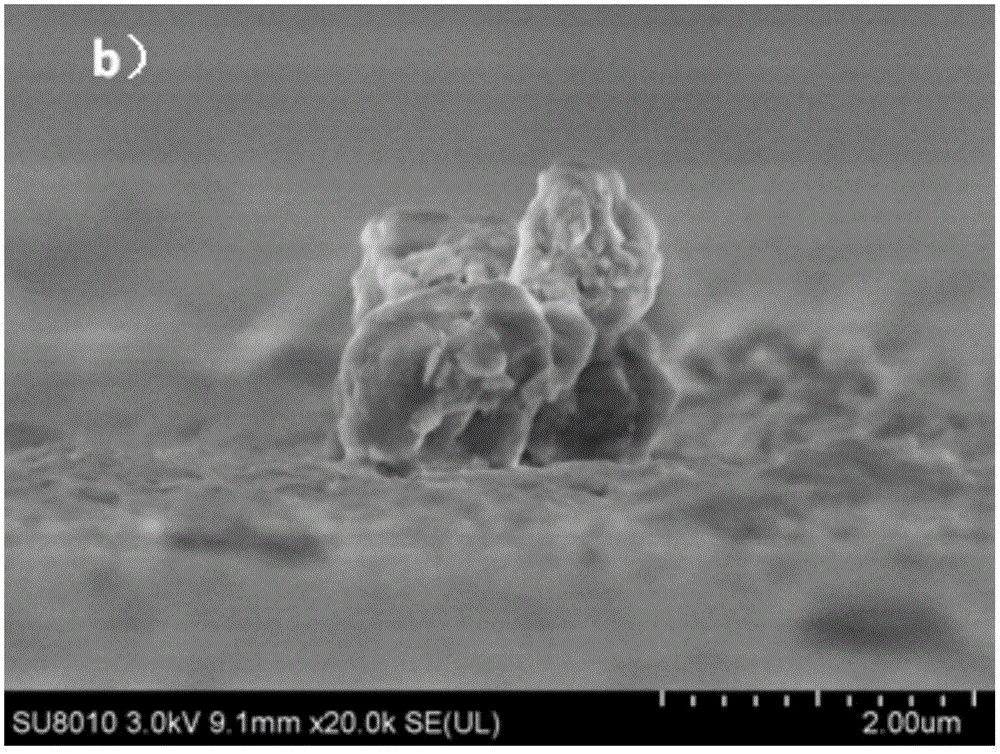

Super-hydrophobic polypropylene film and preparation method thereof

Owner:ZHEJIANG UNIV

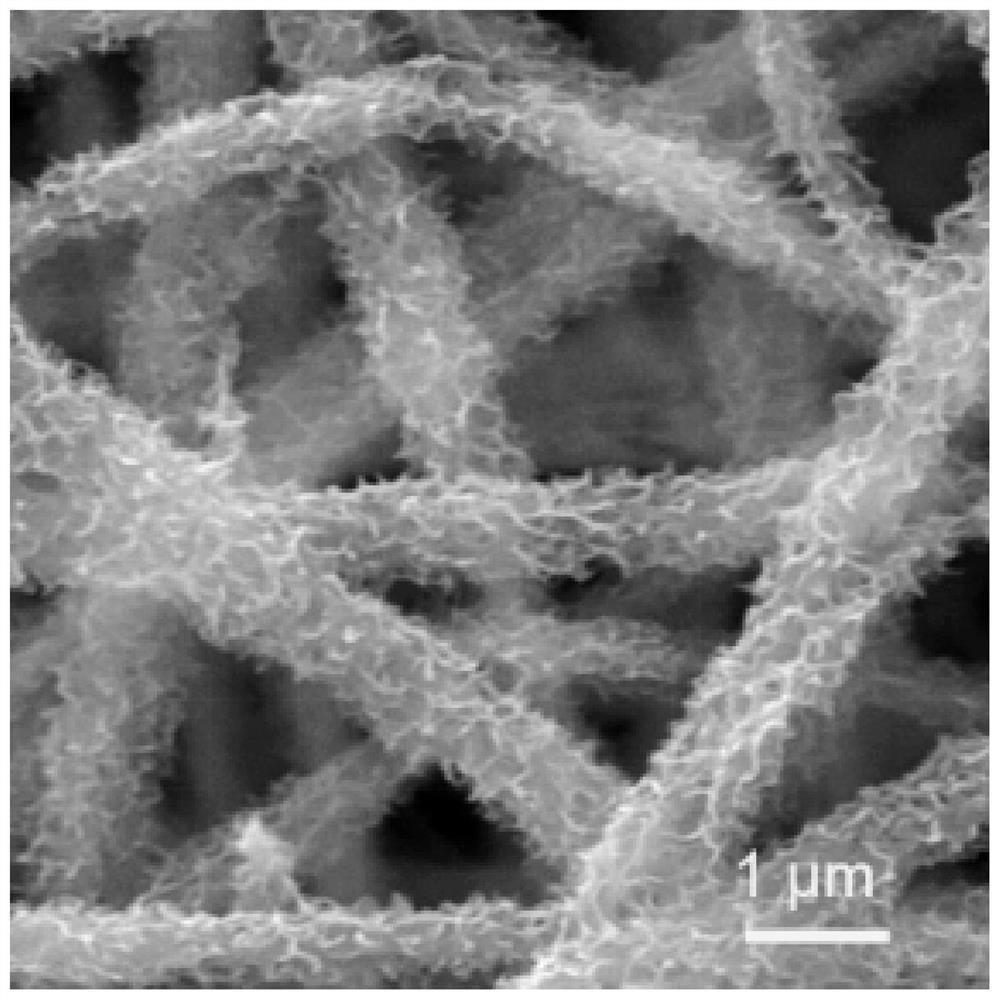

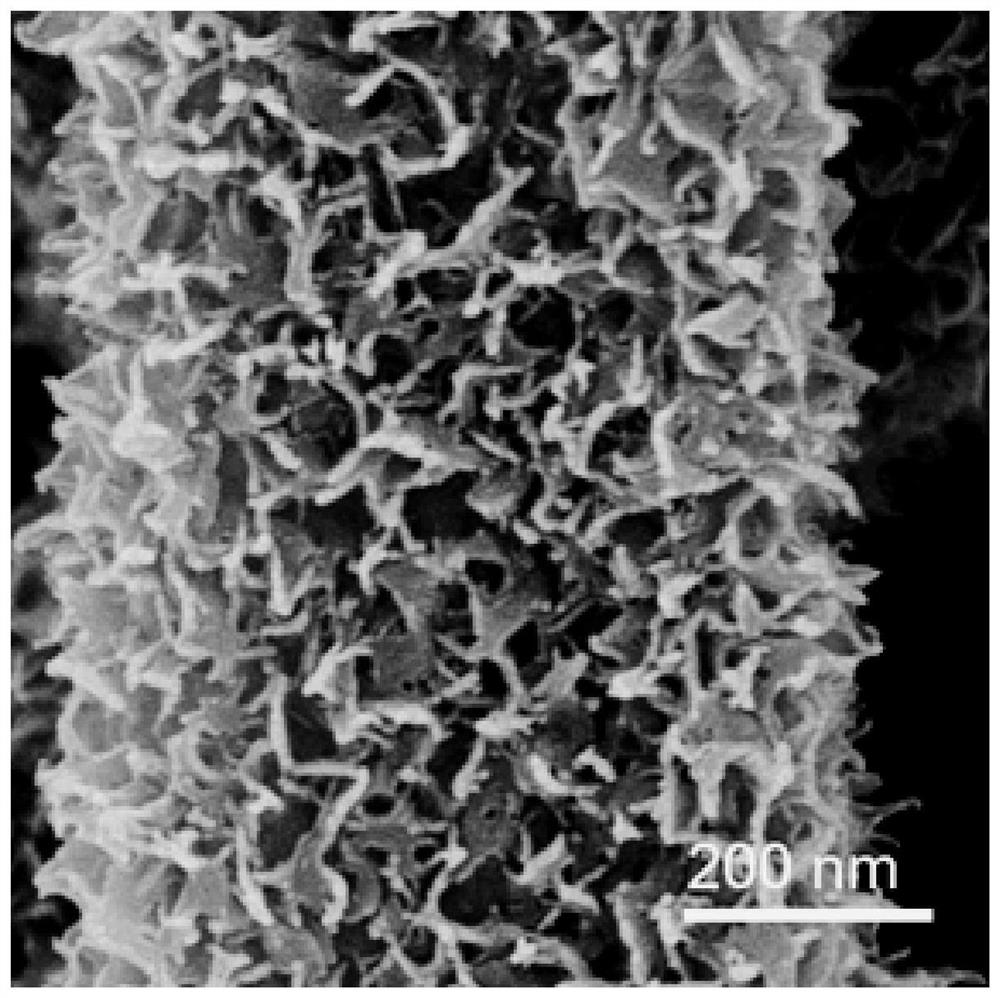

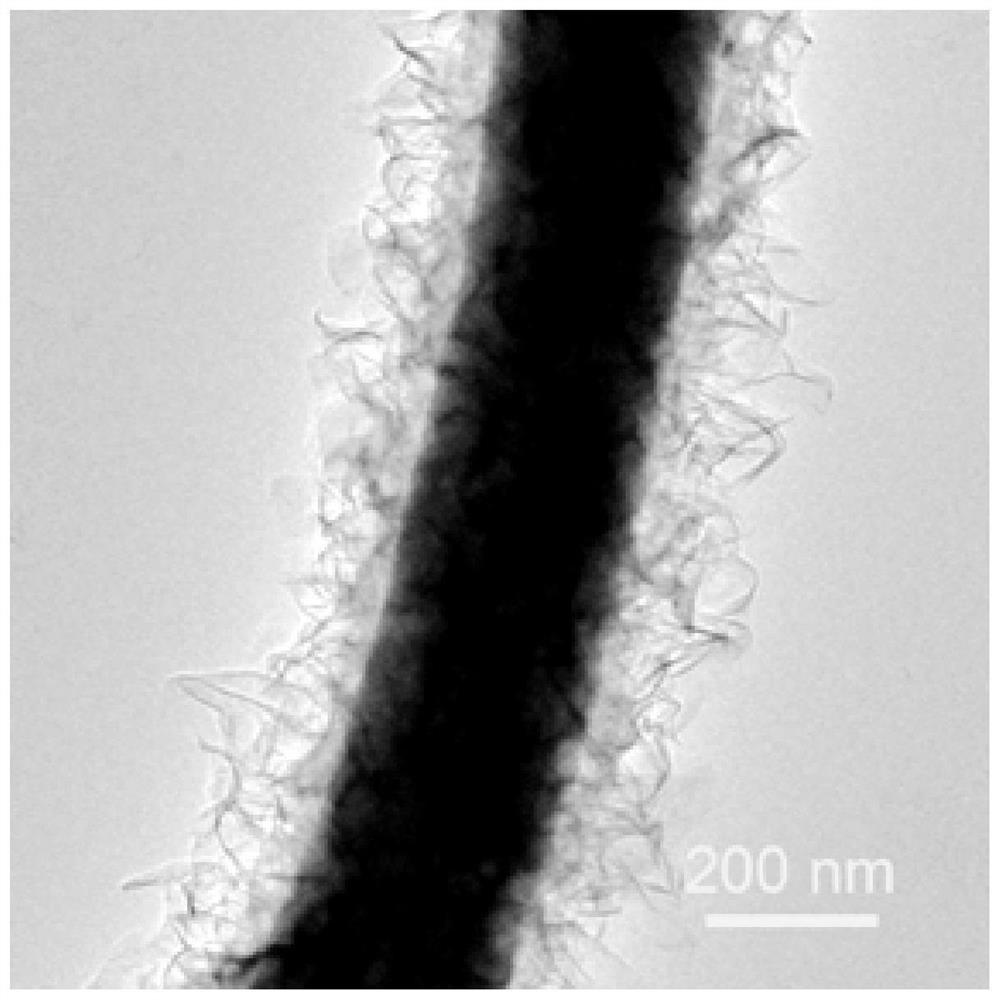

Ceramic nanofibers for liquid or gas filtration and other high temperature (> 1000 °c) applications

In accordance with the invention there are devices and processes for making ceramic nanofiber mats and ceramic filters for use in high temperature and in corrosive environments. The process for forming a ceramic filter can include electrospinning a preceramic polymer solution into a preceramic polymer fiber having a diameter from about 10 nm to about 1 micron and forming a preceramic polymer fiber web from the preceramic polymer fiber onto a collector. The process can also include pyrolyzing the preceramic polymer fiber web to form a ceramic nanofiber mat having a diameter less than the diameter of the preceramic polymer fiber, the ceramic nanofiber mat comprising one or more of an oxide ceramic and a non-oxide ceramic such that the ceramic fiber mat can withstand temperature greater than about 1000° C.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Zirconium hydroxide nanosheet/nanofiber composite membrane and preparation method thereof

Owner:DONGHUA UNIV

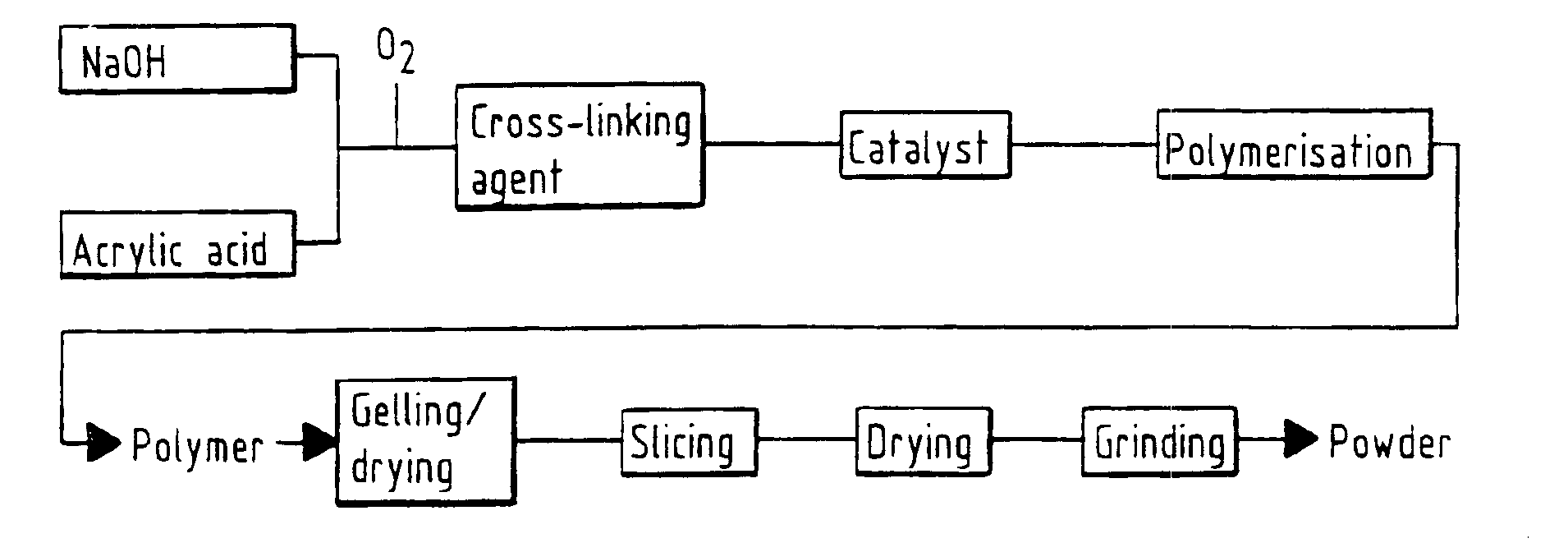

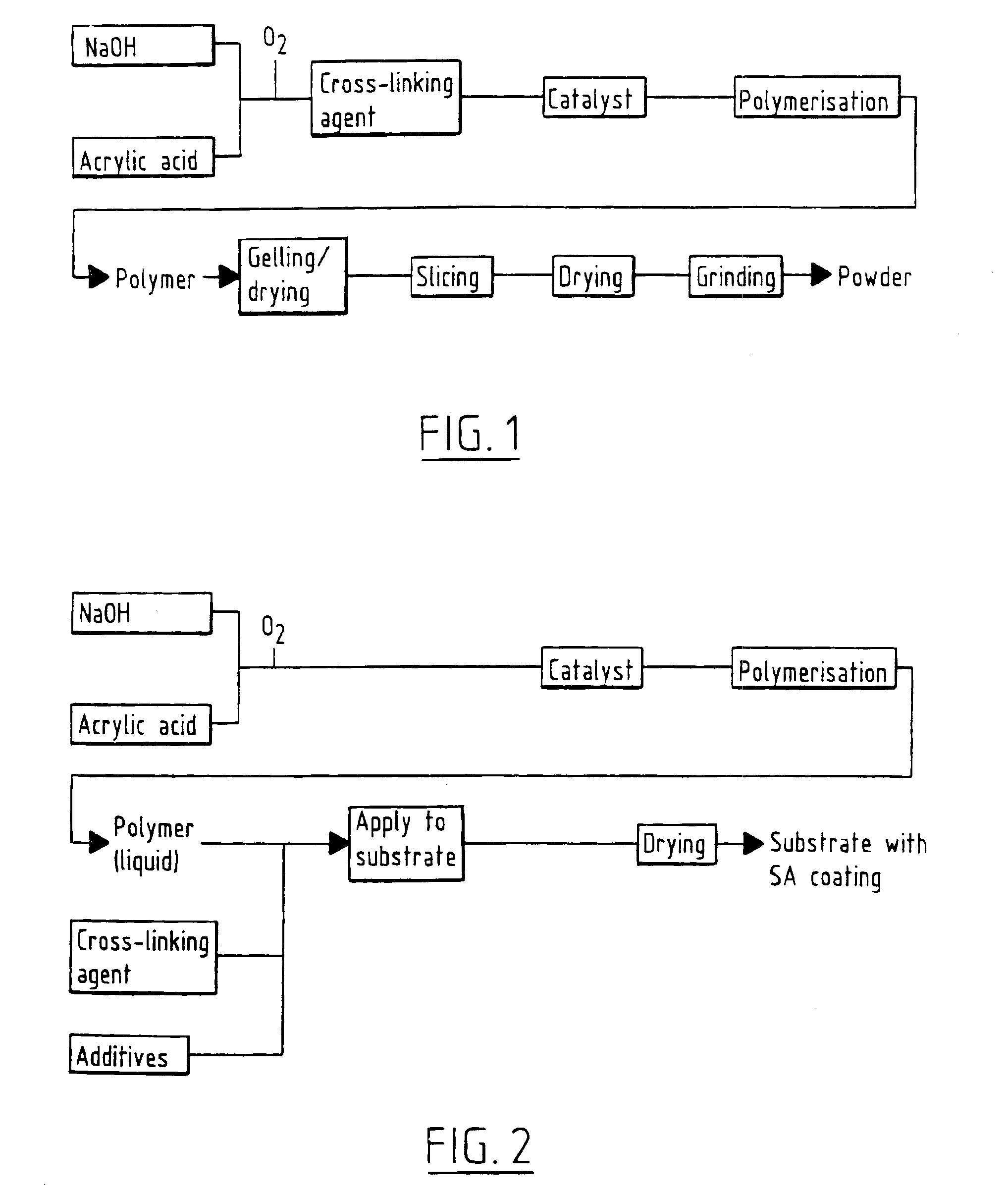

Substrate with super-absorbent material, method for manufacture thereof and use

Owner:EVONIK DEGUSSA GMBH

Profile control and plug removal integrated operation system and method for polymer flooding and injection well

PendingCN114810002AAvoid secondary damageIncrease the amount of suction and deblocking working fluidCleaning apparatusFluid removalWater floodingIntegrated operations

The invention discloses a profile control and plug removal integrated operation system and method for a polymer flooding and injection well, and belongs to the technical field of profile control and plug removal of a polymer injection well in the petroleum drilling and production technology. The method comprises the following steps: manufacturing an artificial high-permeability core and a low-permeability core, evacuating saturated water and saturated oil from the high-permeability core and the low-permeability core, connecting the high-permeability core and the low-permeability core in parallel to form a model for simulating intra-layer and inter-layer heterogeneity of an oil reservoir, performing constant-speed water flooding, injecting a polymer solution into the parallel model at a constant speed, and performing subsequent water flooding until the water content is 90%; the calcium chloride, the spacer fluid and the sodium silicate solution are alternately injected into the parallel model for multiple rounds under constant pressure P profile control, and contact and react in the high-permeability layer to finally generate the silicate gel profile control agent; according to constant-pressure P plug removal, plug removal working liquid is injected into the parallel models, and the models are closed for 12-36 h; and injecting water into the parallel model under the constant-pressure P follow-up water drive, and performing follow-up water drive until the water content reaches 90%.

Owner:CNOOC TIANJIN BRANCH

Hydrophobicity regulation and control method of alkaline polyelectrolyte fuel cell catalyst layer

InactiveCN111740118AHigh absolute performanceImprove water managementCell electrodesPolyelectrolytePtru catalyst

The invention discloses a hydrophobicity regulation and control method of an alkaline polyelectrolyte fuel cell catalyst layer. The method comprises the following steps of firstly, synthesizing a series of fluorine-containing alkaline polyelectrolytes, and dissolving and dispersing the fluorine-containing alkaline polyelectrolytes in an organic solvent (such as dimethyl sulfoxide) to prepare a polymer solution with a certain concentration; then adding the hydrophobic polymer solution and the common polymer solution into the catalyst dispersion solution according to different volume ratios (thehydrophobic polymer solution can be completely used), and carrying out uniform ultrasonic dispersion to prepare catalyst ink; finally, spraying uniformly dispersed catalyst ink on the alkaline membrane, removing the solvent by heating in the spraying process, and placing the alkaline membrane with the catalyst layer between the gas diffusion layers to form a membrane electrode. The method is characterized in that the hydrophilicity and hydrophobicity of the catalyst layer can be adjusted by adding the hydrophobic polymer solution in proportion, the hydrophobic polyelectrolyte is located in athree-phase reaction interface, and the hydrophilicity and hydrophobicity of reaction active sites of the catalyst layer can be accurately adjusted and controlled without introducing the extra electrode components.

Owner:WUHAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap