Anti-shrinkage resin sand mold riser device

A technology of resin sand and anti-shrinkage cavity, applied in casting and molding equipment, molds, cores, etc., can solve the problems of increasing labor intensity of workers, large-area holes in profiles, and difficulty in grinding and cleaning of risers. Pouring efficiency, preventing shrinkage and shrinkage defects, and beneficial to the effect of liquid replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0014] Embodiments of the invention are:

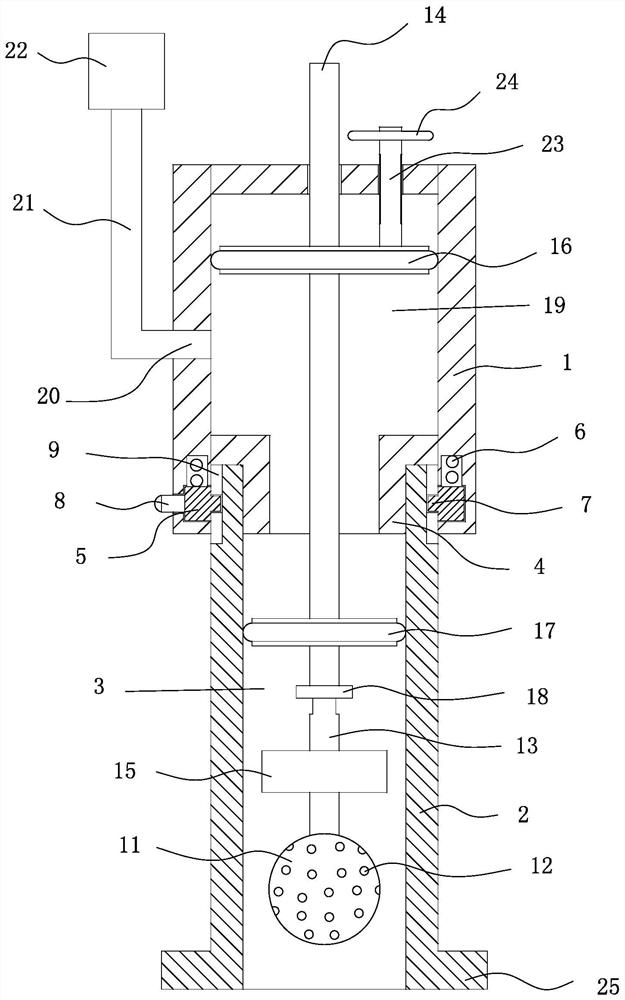

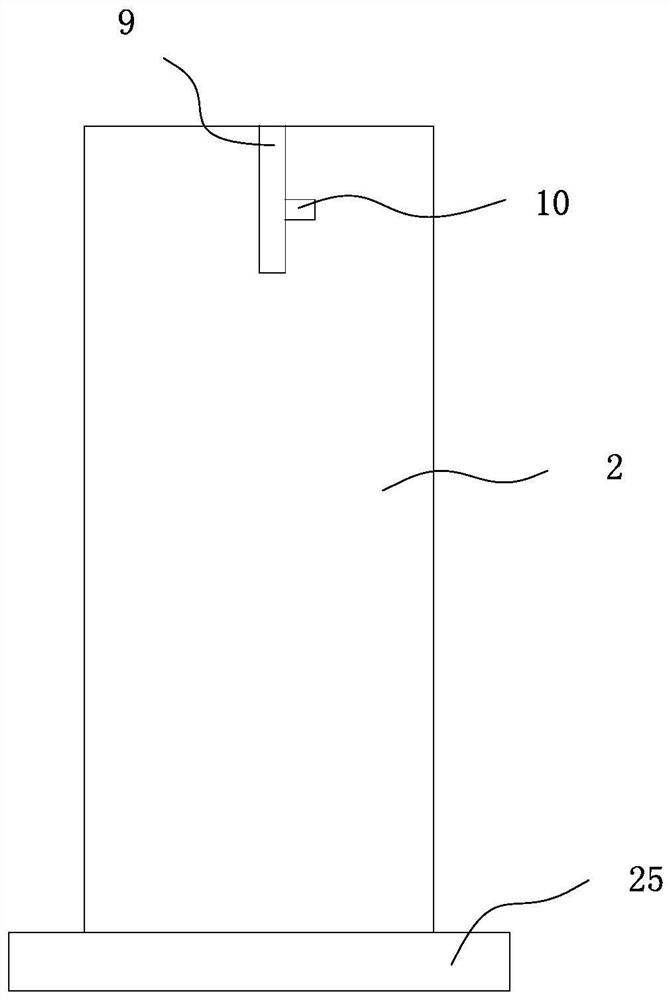

[0015] refer to figure 1 , figure 2 and image 3 As shown, an anti-shrinkage cavity resin sand mold riser device includes a hollow upper part 1 and a lower part 2 in a tubular structure. The upper part 1 and the lower part 2 are clamped and connected, and a through cavity 3 is formed inside. Specifically , the inner surface of the upper part 1 and near the lower end are provided with an embedding groove 4 for the insertion of the lower part 2, and the upper part 1 is rotatably provided with an annular block 5 on the side wall of the embedding groove 4, and the annular block 5 A torsion spring 6 is provided between the block 5 and the upper part, and the side of the annular block 5 facing the embedding groove 4 is outwardly provided with a clamping block 7, and the side of the annular block 5 away from the e

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap