Electric leakage mutual inductor for high-power copper bar measurement

A transformer and high-power technology, applied in the direction of inductors, measuring electrical variables, transformer/inductor cores, etc., can solve the problems of low detection accuracy and magnetic balance characteristics, signal distortion, misoperation, etc., and achieve low manufacturing costs , The production, processing and installation process is simple, and the effect of improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

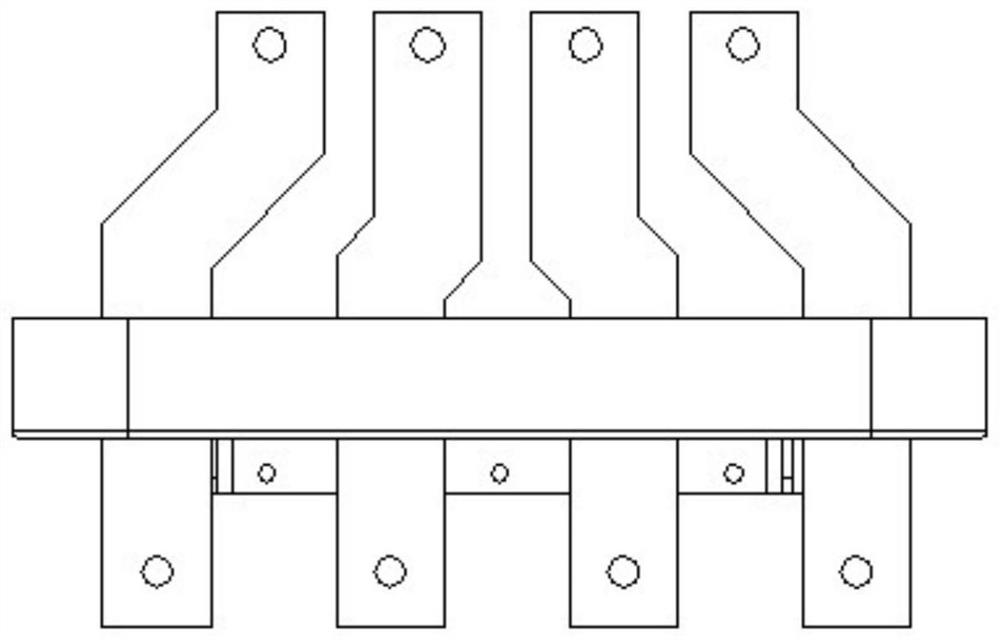

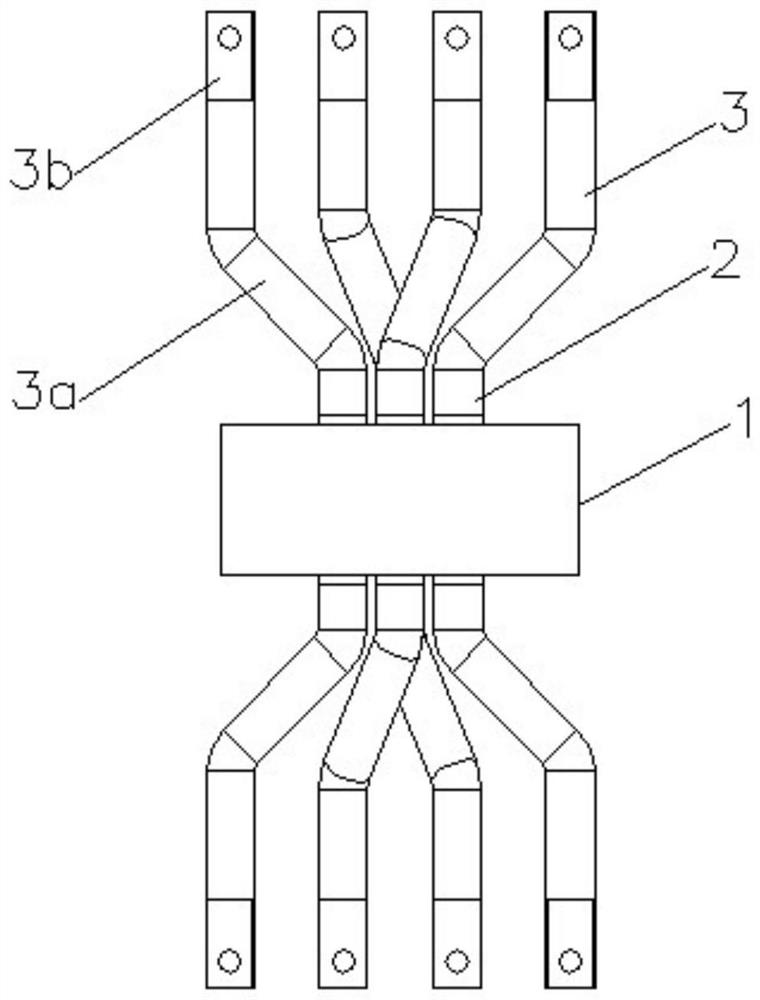

[0037] see Figure 3~Figure 5 , a leakage transformer for high-power copper bar measurement, comprising a transformer housing 1, characterized in that:

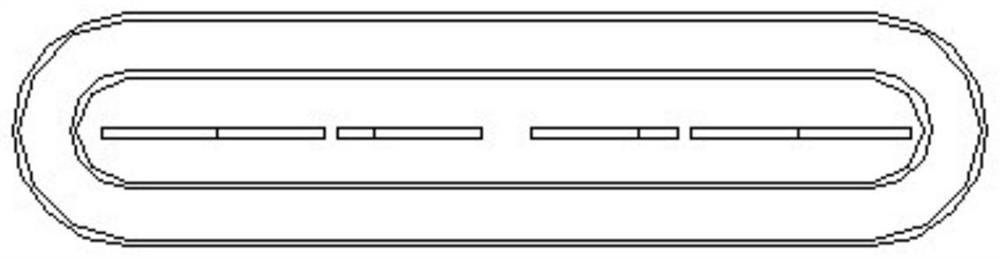

[0038] see Figure 6~Figure 9 , the transformer shell 1 is set as a round box, and a metal shielding layer 11 is connected inside it, and a transformer winding 4 is connected inside the transformer shell 1 outside the metal shielding layer 11, and the mutual inductance inside the metal shielding layer 11 Four through holes 12 are arranged in the device housing 1;

[0039] The metal shielding layer 11 divides the transformer housing 1 into two parts, one is the circular groove 1a located on the outer ring, which is coaxial with the transformer housing 1, and the other is the circular cavity located on the inner ring 1b, the transformer winding 4 is connected in the ring groove 1a, the through hole 12 is set in the circular inner cavity 1b, the centers of the four through holes 12 are connected successively to form a square, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap