Continuous mixing reactor

A technology of mixing reactor and reaction chamber is applied in the field of mechanical manufacturing and processing, which can solve the problems of long time and uneven mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

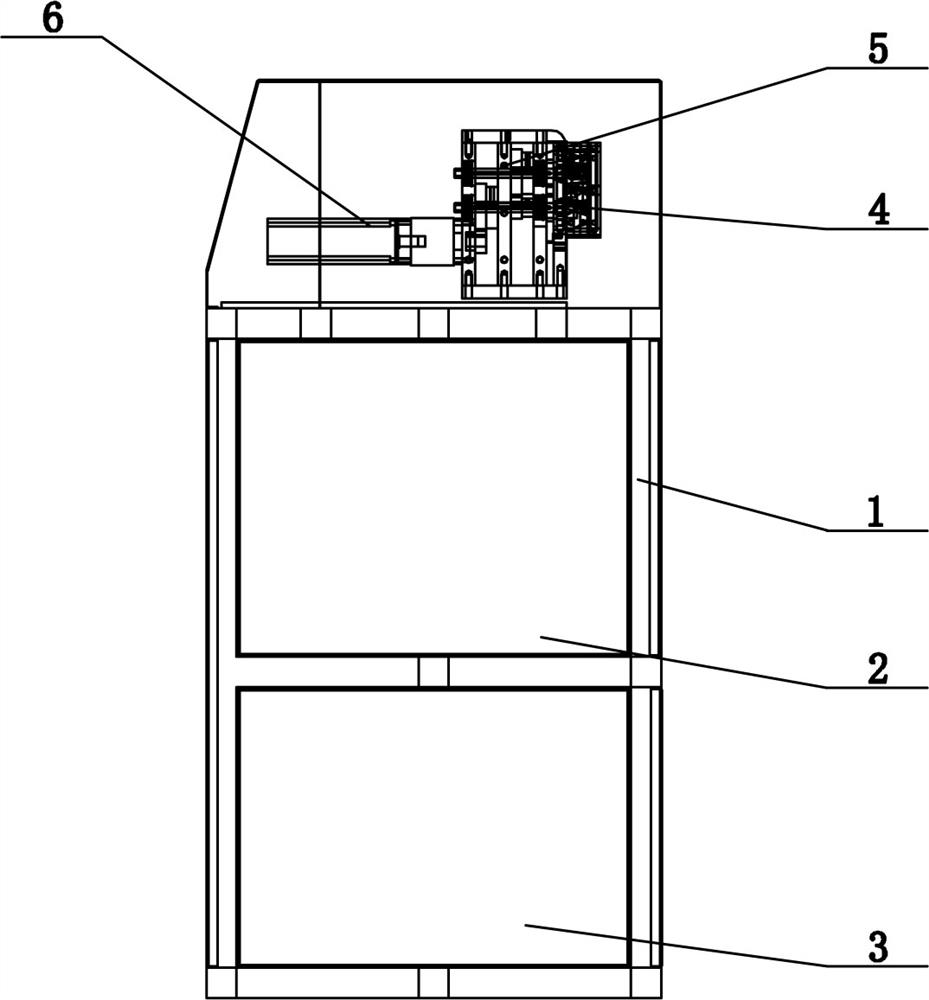

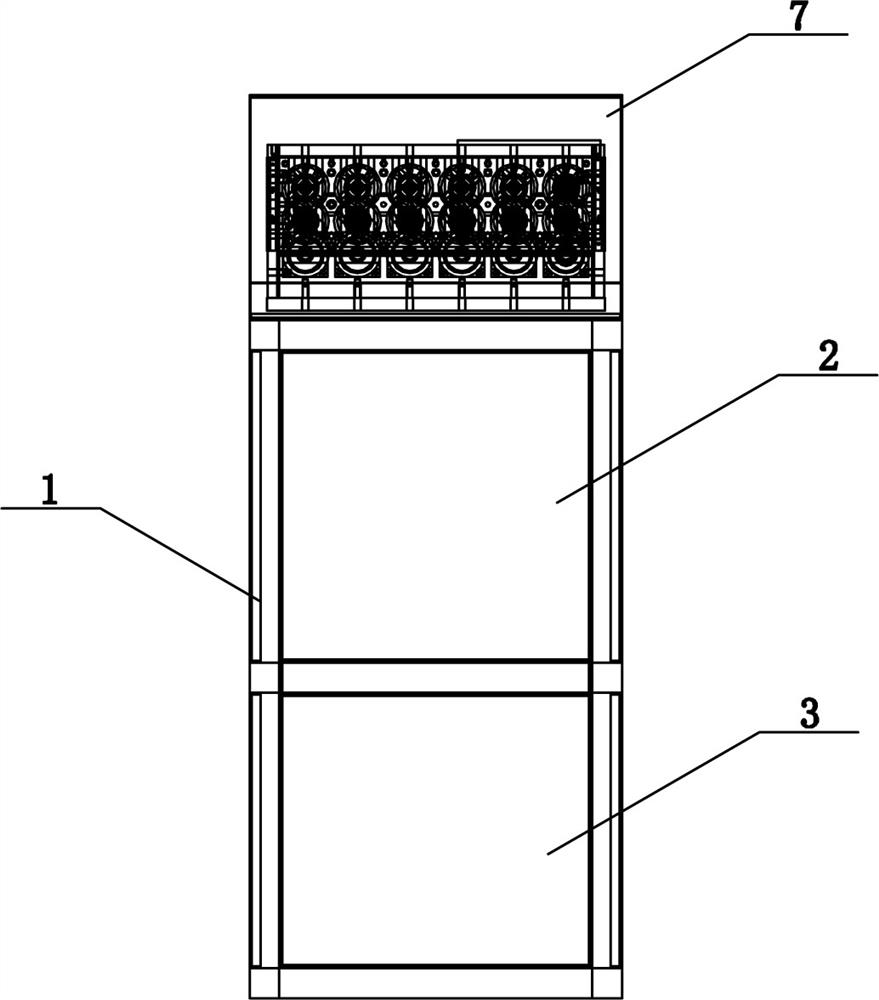

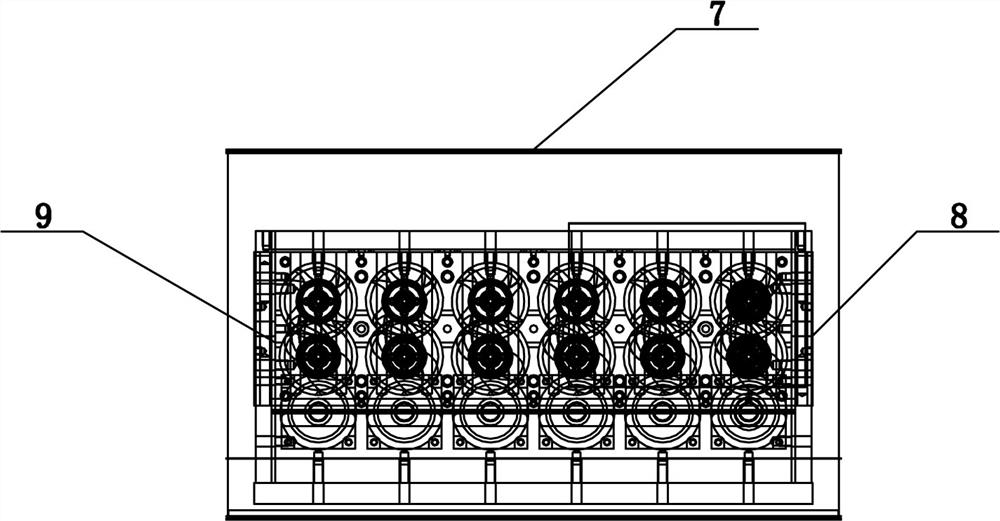

[0017]SeeFigure 1 - Figure 4As shown, the technical solution employed in this particular embodiment is: it includes a host frame 1, an electronically control system 2, a cooling lubricating system 3, a reaction chamber 4, a transmission 5, a servo motor 6, a mixed stirring mechanism 7, a material inlet 8, The material outlet 9, the upper rotor 10, the lower rotor 11; the internal portion of the main frame 1 is mounted above the internal control system 2, and the cooling lubrication system 3 is mounted below the electron control system 2, and the reactive cavity 4 is provided on the electron control system 2. The transmission 5 is electrically connected to the servo motor 6 and is connected to the reaction chamber 4; the main frame 1 is provided with a mixed stirring mechanism 7, and the left and right sides of the mixed stirring mechanism 7 are material inlet 8, material outlet 9, mixed stirring mechanism, respectively. 7 The upper rotor 10 and the lower rotor 11 for the stirred materi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap