Production method of high-strength antibacterial corrugated paper based on online monitoring

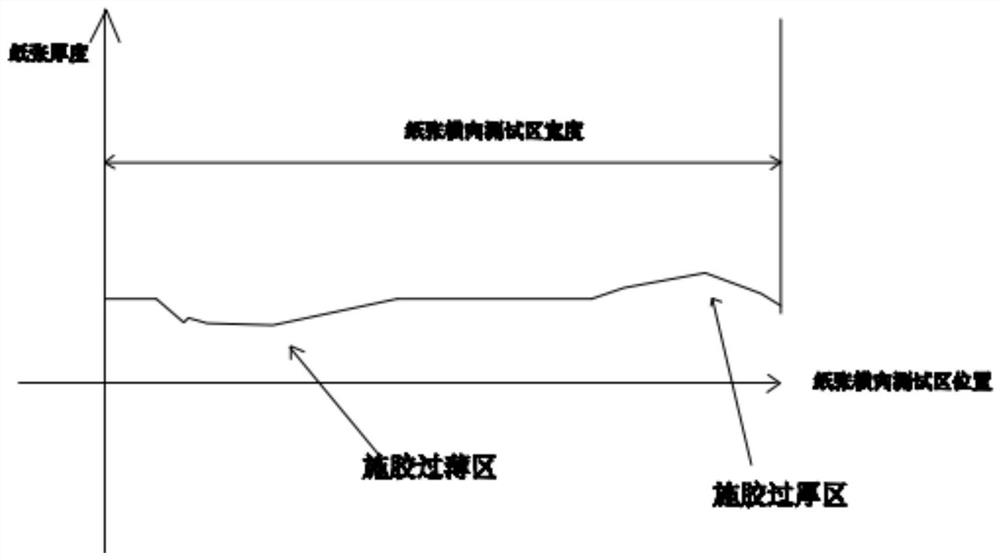

A production method and technology of antibacterial tiles, applied in chemical instruments and methods, papermaking, paper, etc., can solve problems such as difficulty in passing paper, uneven thickness, and inability to print, and achieve the effect of real-time and effective monitoring of production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] see Figure 1-6 , the present invention provides a technical solution:

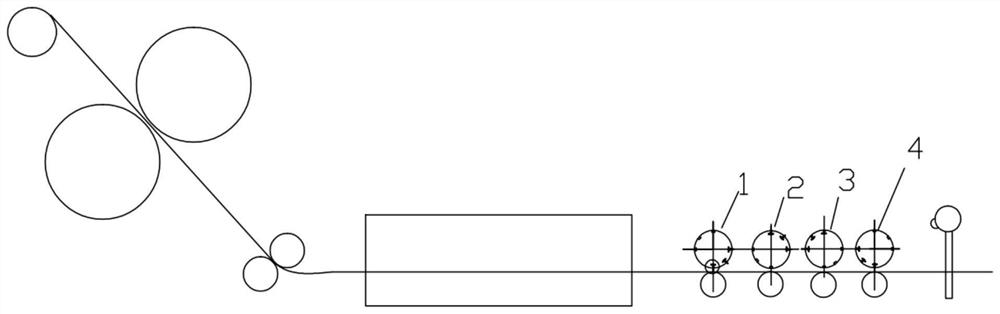

[0047] A method for manufacturing high-strength antibacterial corrugated paper based on on-line monitoring, comprising the following steps:

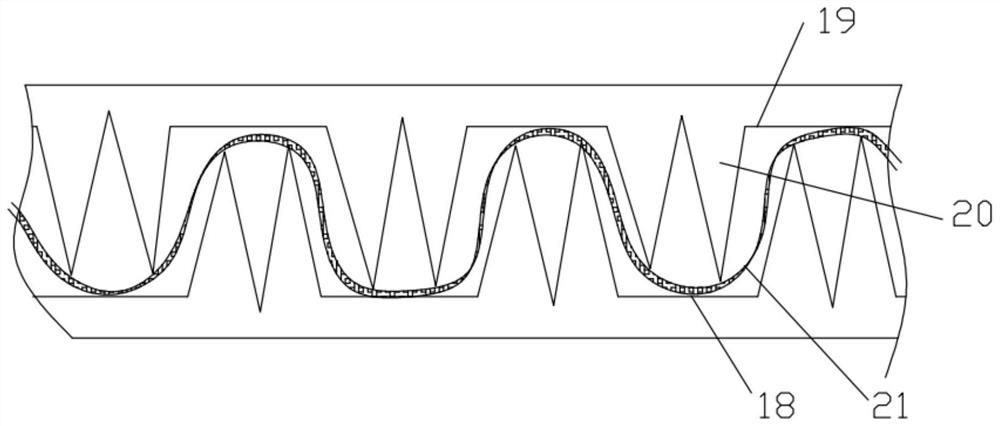

[0048] Step 1: Take the antibacterial paper of the core layer and press it into a wave shape by hot pressing;

[0049] Step 2: Take the first auxiliary support layer and the second auxiliary support layer, and stick the first auxiliary support layer and the second auxiliary support layer on the bottom surface and the top surface of the core antibacterial paper by adhesive;

[0050] Step 3: Take the first face paper layer and the second face paper layer; the first face paper layer is pasted on the top surface of the second auxiliary support layer by adhesive; the second face paper layer is pasted on the first face paper layer by adhesive on the bottom surface of the auxiliary support layer;

[0051] Step 4: After the corrugated paper completed in step 3 is dri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap