Preparation method of water-based starch adhesive

A starch adhesive, water-based starch technology, applied in the directions of starch adhesive, adhesive type, non-polymer adhesive additive, etc. Long time and other problems, to achieve the effect of shortening the processing turnover cycle, good flexibility, and high composite tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises the following steps:

[0029] Step 1): Weigh the water and α-amylase according to the raw material formula, add them into the reaction kettle, stir and mix evenly;

[0030] Step 2): Weigh the starch according to the raw material formula, and slowly add the starch into the reaction kettle while stirring at a speed of 300-350r / min, and at the same time, the reaction kettle starts from room temperature Gradually raise the temperature; based on 100 parts by weight of the starch adhesive, the feeding rate of the starch is 1.7-4.5 parts / min, the heating rate of the reactor is 1-2°C / min, and the temperature of the reactor is Complete all feeding before reaching 60°C; after completing the feeding, raise the temperature of the reactor to 80-85°C, keep constant temperature, maintain the stirring speed, and react for 50-70 minutes;

[0031] Step 3): Weigh the cross-linking agent according to the raw material formula, and slowly add the cross-li

Embodiment 1

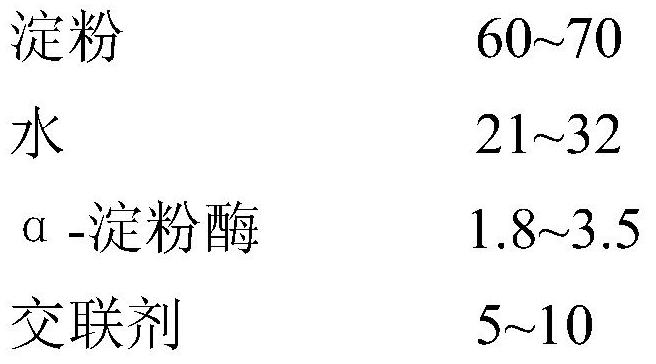

[0042] The formula of the water-based starch adhesive of embodiment 1 is as follows:

[0043] In 100 parts by weight of the water-based starch adhesive of embodiment 1, its raw material formula comprises the component of following parts by weight:

[0044]

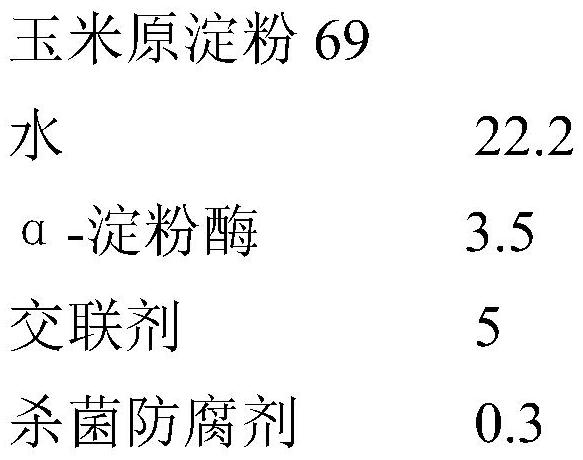

[0045] Among them, raw corn starch is an edible corn starch (grade 1) product purchased from Shandong Huayi Corn Technology Co., Ltd.; α-amylase is a XK-86 product purchased from Taizhou Ente New Material Co., Ltd.; the crosslinking agent is carbonized The diimine crosslinking agent was purchased from Shanghai Zhuo Tu New Material Technology Co., Ltd. DX-W140 product; the bactericidal preservative was purchased from Guangzhou Zhongwan New Material Co., Ltd. U-W66 product.

[0046] The preparation process of the water-based starch adhesive of embodiment 1 is as follows:

[0047] Step 1): Weigh water (tap water or purified water) and α-amylase according to the above raw material formula, add them into the reaction kettle, s

Embodiment 2

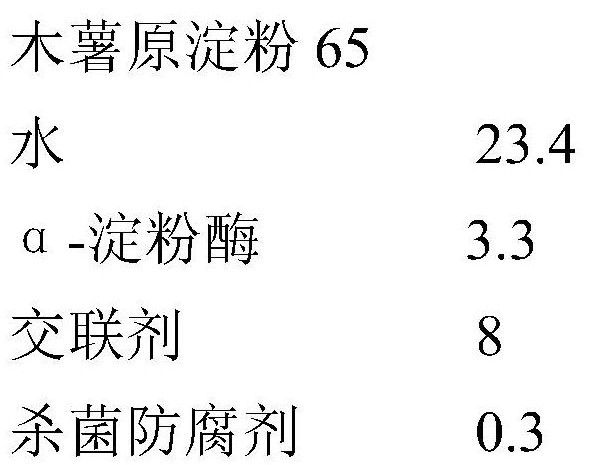

[0052] The formula of the water-based starch adhesive of embodiment 2 is as follows:

[0053] In 100 parts by weight of the water-based starch adhesive of embodiment 2, its raw material formula comprises the component of following parts by weight:

[0054] Raw corn starch 60

[0055] water 31

[0056] α-amylase 3

[0057] Crosslinker 6

[0058] The sources of raw corn starch, α-amylase and crosslinking agent are all the same as in Example 1.

[0059] The preparation process of the water-based starch adhesive of embodiment 2 is as follows:

[0060] Step 1): Weigh water (tap water or purified water) and α-amylase according to the above raw material formula, add them into the reaction kettle, stir and mix evenly;

[0061] Step 2): Weigh the raw corn starch according to the above raw material formula, and slowly add the starch into the reactor while stirring at a speed of 350r / min, and at the same time, the reactor starts to gradually heat up from room temperature (about 22°C)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap