Thermal management system and heating method of battery pack

A heat management system and heating method technology, applied in the thermal management system and heating field of battery packs, can solve the problems of power consumption of power batteries, high energy consumption of automobiles, and decreased mileage of automobiles, so as to achieve high utilization rate and increase mileage , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Further detailed explanation through specific implementation mode below:

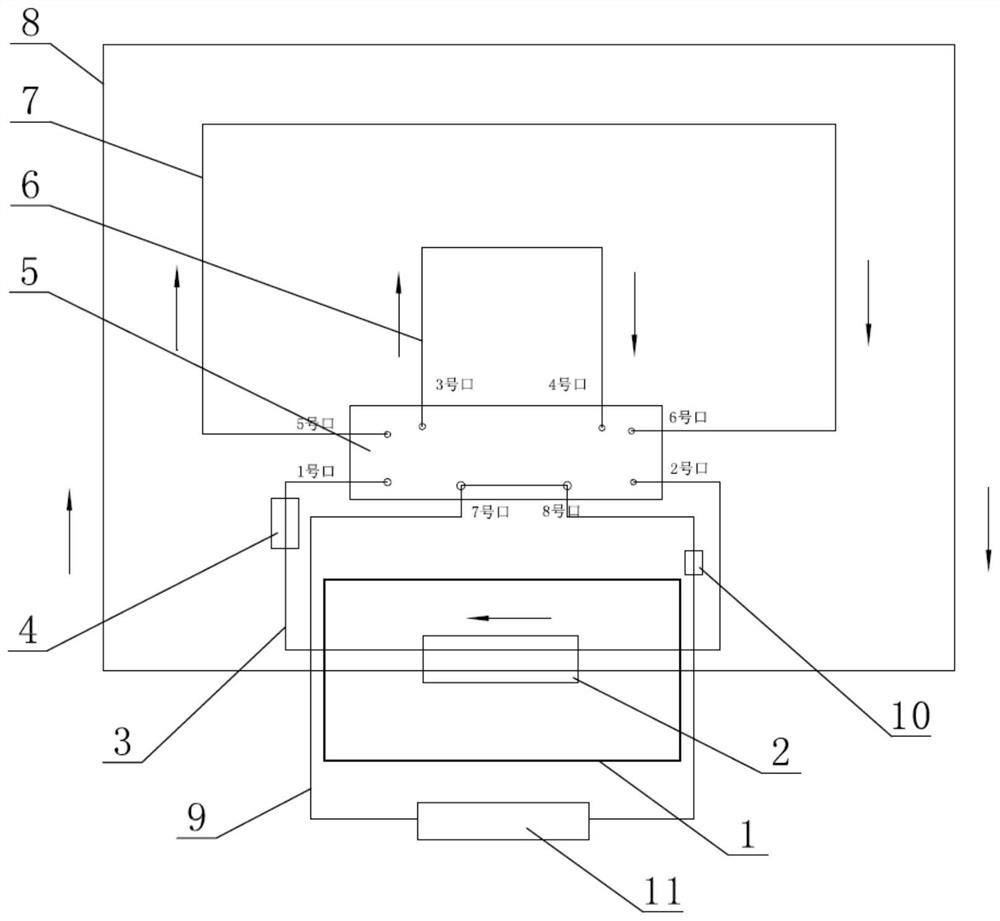

[0035] Such as figure 1 As shown, this embodiment provides a thermal management system for a battery pack, which includes a battery pack heating circuit and a battery pack heat dissipation circuit. The liquid cooling plate 2 of the channel dissipates heat to the battery pack.

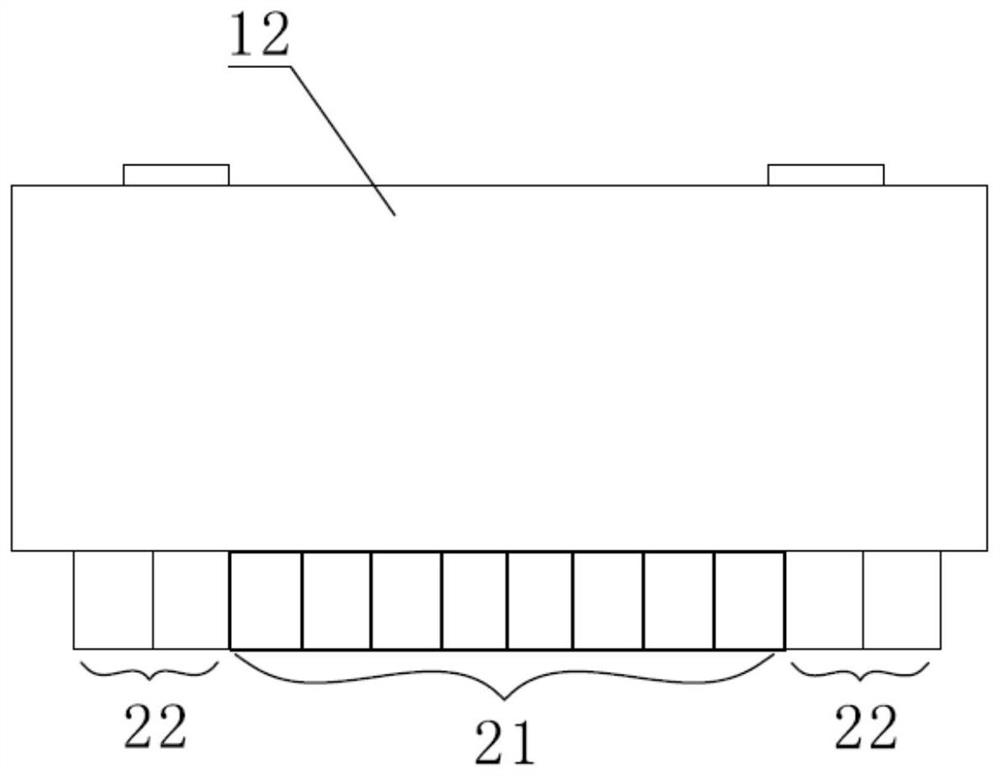

[0036] In this embodiment, the liquid cold plate 2 includes a first cavity 22 and a second cavity 21 that are independent of each other; the liquid cold plate 2 is preferably a harmonica tube, and a part of the harmonica tube channel in the liquid cold plate 2 is the second cavity 21 ; another part of the harmonica tube channel in the liquid cold plate 2 is the first cavity 22 . Such as figure 2 As shown, the multiple harmonica tube channels in the middle of the liquid cold plate 2 in this embodiment are the second cavity 21, and the multiple harmonica tube channels on both sides of the liquid cold plate 2 are the first c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap